Our high-tech 2-phase decanter centrifuge offers reliable and efficient performance, ensuring maximum separation of solids and liquids. With advanced technology and precision engineering, this centrifuge provides superior results in various industrial applications. Its innovative design and features make it a top choice for businesses looking to optimize their separation processes.

Our High-Tech 2-Phase Decanter Centrifuge is designed to serve your industrial separation needs with utmost reliability, efficiency, and maximum separation performance. We serve excellence by providing you with a cutting-edge solution that ensures optimal results in separating solids and liquids. Our commitment to innovation and quality guarantees a durable and high-performing product that exceeds industry standards. With a focus on customer satisfaction and cost-effectiveness, we serve your operational needs by delivering a dependable and efficient centrifuge that maximizes productivity and minimizes downtime. Trust us to serve you with the best-in-class technology for your separation requirements.

We serve with our High-Tech 2-Phase Decanter Centrifuge, built to deliver reliable and efficient performance for maximum separation. Our cutting-edge technology ensures consistent and precise results, making it a trusted solution for various industries. With a focus on quality and durability, our decanter centrifuge offers unparalleled efficiency and cost-effectiveness. We serve our customers by providing a solution that meets their unique needs, offering reliable operation and maximum separation capabilities. Trust in our expertise and dedication to serving you with the best-in-class decanter centrifuge for all your separation needs.

Decantador from Shenzhou

Shenzhou Decanter centrifuge from Chinese leading manufacturer since 1980, covering area of 80000M2 ,there are 2500 staffs, and have obtained both CE and ISO. As the leading manufacturer in the field of centrifugal separation technology in China, Shenzhou have more than 200 areas of application which have been tested in separation technology , besides have a good track record in the decanter field.

The Shenzhou decanter centrifuge batch Centrifuge & Separator is made from high-quality materials, including stainless steel, and is designed to withstand harsh operating environments. Its compact design makes it easy to install and maintain, while its low noise operation ensures a safe and comfortable work environment.

In addition to its superior performance and reliability, the Shenzhou decanter centrifuge batch Centrifuge & Separator offers a range of marketing advantages. Its advanced technology and robust construction demonstrate a commitment to quality and innovation that customers are sure to appreciate. Additionally, its efficiency and effectiveness can help businesses reduce waste volume and increase production efficiency, delivering significant cost savings over time.

Product Description

Shenzhou decanter centrifuges are nowadays used throughout the world in key industries, such as the chemical and pharmaceutical industry, biotechnology, starch technology, oils and fats recovery, in environmental technology and mineral oil recovery. This foundation is built on to constantly develop specific processes for new areas of application and improving existing processes. Experience and knowledge, which is being applied more and more intensively for starch and protein recovery.

The rotating part of these decanter tricanter centrifuges is mounted on a compact, in-line frame, with main bearings at both ends. Vibration dampers are placed under the frame. The rotating part is enclosed in a casing with a cover and a bottom section with integrated outlets for both solids and the liquid being removed.

Quality Assurance

- JB/T502-2015 Chinese national standard of decanter centrifuge

- 2006/42/EC Machinery Directive

- 2014/35/EU Low voltage Directive

- 2014/30/EU Electromagnetic compatibility Directive

- Quality management system of ISO9001-2000

Working Principle

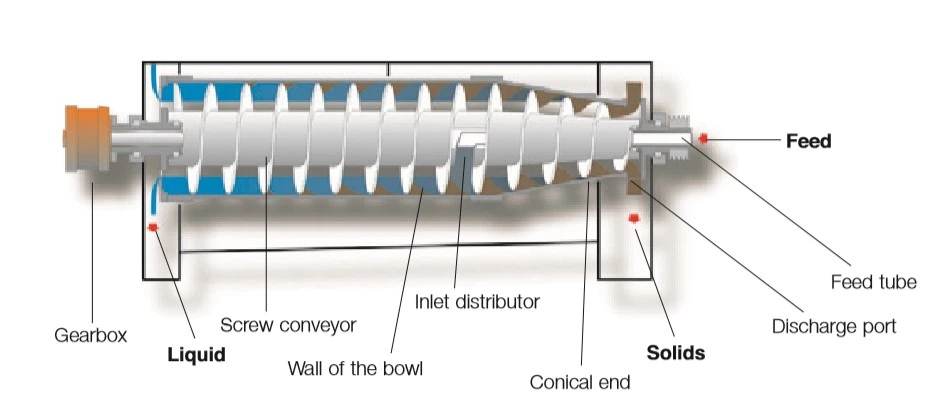

2 - Phase Separation

The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.

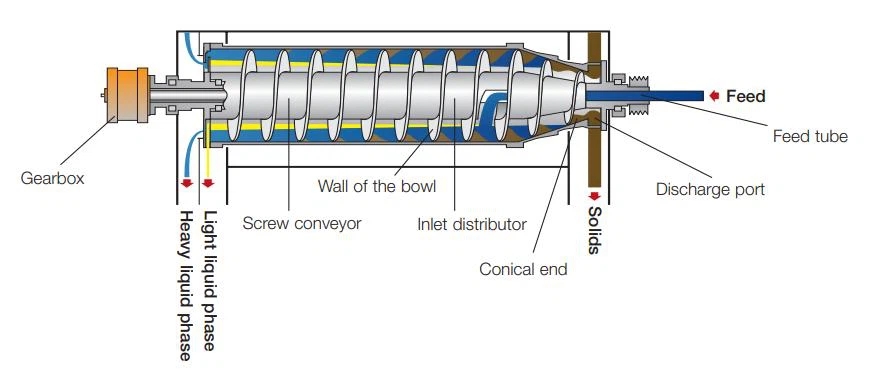

3 - Phase Separation

The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub. The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged in the normal way.

Material

The bowl, conveyor, inlet tube, outlets, cover and other parts in direct contact with the process media are all made of stainless steel. The discharge ports, conveyor flights and feed zone are protected with materials that are highly resistant to erosion. The frame is made of mild steel with an epoxy enamel finish.

Wear Protection

Shenzhour supply a wide range of wear protection for decanter centrifuge to meet the requirements of the many different applications, including:

- Welded hard facing or spray coating

- Ceramic

- Tungsten carbide tiles

- Plastic liners

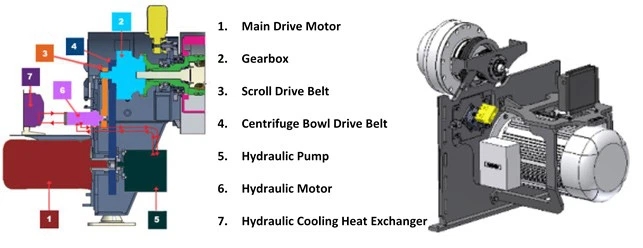

Available Back-Drive Transmission Types

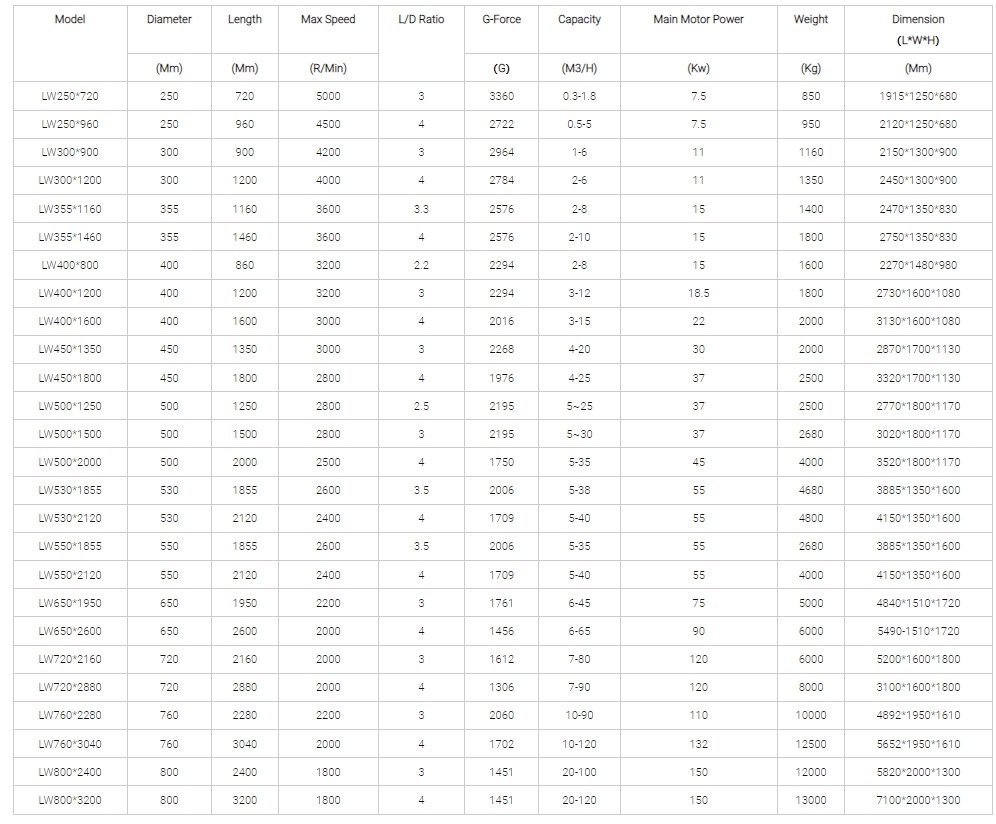

Technical Parameter

After Service

Technical service of decanter centrifuge:

- technical direction when installation, debugging

- training for operation and maintain worker

Training:

- separator working principle and structure

- operation regulation and attention

- machine maintains

Experience

Shenzhou Decanter has been developing and manufacturing centrifuges more than 40 years, and is one of the Chinese leading manufacturer. has more experience and expertise than any other decanter centrifuge manufacturer when it comes to applying and using decanter centrifuge for the purpose of continuous separation.

For more information, please refer to: www,lnszjx.com

Manufacturing

Workshop

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of 2 phase decanter centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Production Line equipment and an unforgettable experience of partnering with us.

In essence, a long-standing 2 phase decanter centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the 2 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the 2 phase decanter centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1