Sludge Dewatering Horizontal Type Spiral Centrifugal Machine For Industrial And Domestic Sewage Treatment Horizontal Screw Centrifuge

Applied in our manufacturing process, the technologies have speeded up the whole process and guaranteed the product quality.In the application range(s) of Water Treatment Machinery,Sludge Dewatering Horizontal Type Spiral Centrifugal Machine for Industrial and Domestic Sewage Treatment is of great use.

The Horizontal Decanter Centrifuge is a high-efficiency machine designed for industrial and domestic sewage treatment, featuring a 2 phase decanter for optimal separation of solid and liquid phases. With low power consumption and large handling capacity, this centrifuge offers automatic running for 24 hours of continuous operation. Its reliable safety guard and high corrosion resistance make it suitable for a wide range of applications in industries such as pharmaceutical, chemical, and food-making.

At our company, we serve industries and households in need of efficient sewage treatment solutions with our Horizontal Decanter Centrifuge. Our state-of-the-art technology ensures effective separation of solids from liquids, delivering clean and safe wastewater discharge. With our focus on quality and reliability, we guarantee high performance and long-term durability for all our customers. We serve our clients by providing a cost-effective and eco-friendly option for sewage treatment, meeting regulatory standards and promoting environmental sustainability. Trust us to serve you with top-notch products that prioritize efficiency, effectiveness, and environmental responsibility.

At our company, we serve the need for efficient and reliable sewage treatment solutions with our Horizontal Decanter Centrifuge. Designed for both industrial and domestic applications, this centrifuge offers unmatched performance in separating solids from liquids. Our team is dedicated to providing top-notch customer service and technical support to ensure smooth operations and maximum productivity. With a focus on quality and innovation, we serve as your trusted partner in wastewater treatment solutions. Experience the difference with our Horizontal Decanter Centrifuge and let us serve your needs for a cleaner and sustainable environment.

Product Description

Horizontal type spiral precipitated centrifugal machine is called horizontal type spiral centrifugal machine for short. lt is a high efficiency horizontal type spiral centrifugal equipment for discharging and precipitation. Generally, it can be divided into horizontal type spiral filtering centrifugal centrifugal machine and horizontal type spiral pricipitated centrifugal machine. lt is widelly used for dehydration for the sludge in industrial and domestic sewage, besides, it is also used in pharmaceutical factory, chemical industry and food-making industry.

Application

|  |

| Characteristics 1. low power consumption 2. large handling capacity 3. automatic running 4. 24 hours continuous operation 5.High corrosion resistance 6.Reliable safety guard |

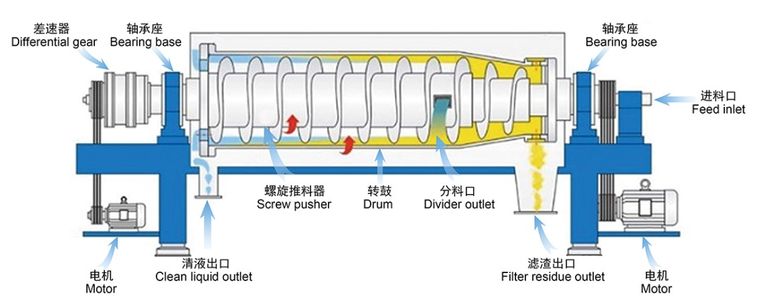

Horizontal Decanter Centrifuge is mainly composed of a conical drum, screw pusher, differential system, bearing base, frame, housing, main and auxiliary motor and electrical system. The main motor drive the drum and the second motor drives the planetary gear differential, which generates the drum and spiral differential. Under the strong centrifugal force produced by the high-speed rotation, the centrifuge can be separated continuously.

The drum and the screw pusher rotate at a certain differential speed and high speed. The material continuously enters the feeding tube's spiral feeding chamber and then accelerates and enters the drum. Under the centrifugal force field, the heavier solid phase deposits on the drum wall to form the sediment layer.

The solid deposits are continuously pushed to the drum's cone end by the screw pusher and discharged from the slag discharge outlet after drying in the drying zone. The lighter liquid phase forms an inner liquid ring, which continuously overflows the drum from the overflow outlet at the drum's large end and discharges out of the machine through the outlet.

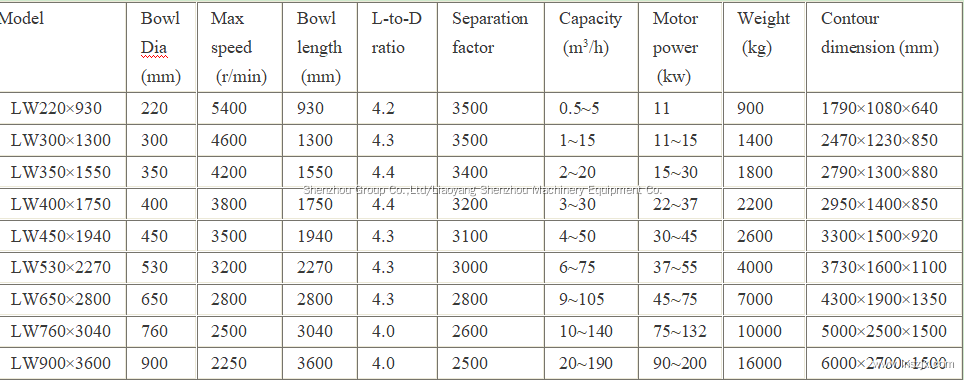

Technical Parameters:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1