Our industrial centrifuge, specifically designed for high-speed drilling mud decanting, provides efficient solid-liquid separation in the petroleum drilling fluid industry. It is capable of quickly recovering heavy components like barite in heavy mud systems to reduce density and is ideal for removing harmful solid phases in deep wells. With features like continuous operation, easy installation, and strong material adaptability, this drilling mud decanter centrifuge offers significant advantages for industrial centrifuge suppliers and users alike.

At Industrial Centrifuge, we serve the needs of industries requiring efficient separation of solids from liquids with our High-Speed Drilling Mud Decanter. Our state-of-the-art centrifuge technology ensures superior performance, reliability, and durability for optimal productivity. We understand the importance of precision and speed in your operations, and our decanter is designed to deliver exceptional results consistently. With our commitment to quality and innovation, we strive to exceed your expectations and provide you with the tools you need to succeed. Trust Industrial Centrifuge to serve you with excellence and make your processes more efficient and cost-effective.

At Industrial Centrifuge, we serve the drilling industry by providing high-speed decanter centrifuges designed specifically for separating drilling mud. Our industrial centrifuges are engineered to efficiently remove solids from drilling fluids, improving overall drilling efficiency and reducing downtime. With a focus on quality, reliability, and cutting-edge technology, we are committed to delivering top-notch equipment to meet the demanding needs of the drilling industry. Our customer-centric approach ensures that we serve our clients with tailored solutions and excellent customer service. Trust Industrial Centrifuge for all your drilling mud decanter needs.

The Explosion-Proof drilling mud decanter centrifuge is manily used to dehydration for the all kinds of sludge and the drilling mud in oilfield. Drilling well solids control Centrifuge is the key equipment in treatment of harmful superfine solid in drilling liquid. remove harmful fine drill solids such as debris, etc. in the mud fluid, or recover weighting materials such as barite etc. so as to reduce the cost of mud fluid.

Products Description

The high speed variable-frequency horizontal spiral Drilling mud centrifuge is a specialized equipment primarily used for solid-liquid separation in the petroleum drilling fluid industry. The machine is a new product developed to absorb the advantages of foreign centrifuges and according to the rapid development of China's oil drilling centrifuges. It processes a large volume of light weight mud systems, and the processing volume should be appropriately reduced in heavy mud systems. In heavy mud systems, it can quickly recover heavy components such as barite to rapidly reduce the mud density. It is capable of efficiently removing harmful solid phases in deep and complex wells, and the rotational speed can be adjusted according to drilling needs, ranging from 0 to 3000 rpm, to find the appropriate speed based on mud particle size and density.

According to different rotating speed, it can be defined as middle speed, high speed and high speed VFD centrifuge. It is mainly use for recycling the barite, removing the fine solid particles sized in 2-7μm, controlling the density and viscosity of drilling fluid to keep the drilling fluid performance. It is widely used in solid control system for drilling mud to separate the solids phase of mud, remove harmful fine drill solids such as debris, etc. in the mud fluid, or recover weighting materials such as barite etc. so as to reduce the cost of mud fluid.

Additionally, this high speed centrifuge machine-- Drilling Fluid Decanter Centrifuge offers strong material adaptability, continuous operation, ease of operation, easy installation, low operating costs, and a small footprint, among other significant advantages. It has good separation effect In oil and gas drilling, horizontal directional drilling, micro tunnel, tunnel construction, drilling waste management and wastewater treatment.

Working Principle

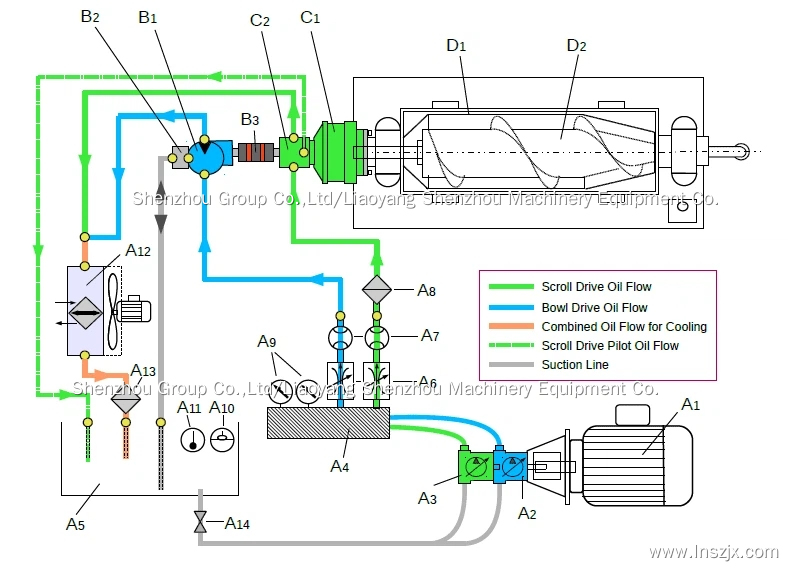

This machine operates based on the settling principle and is designed for the separation of solid and liquid phases in a suspension. The suspension enters the spiral pusher through the feed pipe, accelerates after passing through the accelerator, and then enters the drum. Under the influence of centrifugal force, the solid phase is thrown towards the inner wall of the drum. The spiral blades push the solid phase sediment through the slag discharge outlet. The lighter liquid phase is continuously clarified within the drum and flows towards the large end of the drum, exiting through the overflow outlet.

Structural Feature

1. Structure Of Drilling Mud Decanter Centrifuge

● Drum

The Drum Is Divided Into Cylindrical And Conical Sections And Has Components Such As The Large End Shaft, Differential,Connecting Plate, And Auxiliary Motor Belt Pulley On The Left End. The Right End Includes The Small End Shaft, Main Motor Belt Pulley, And Feed Pipe. Rib Strips Are Welded Inside The Drum To Prevent Material Slippage. It Has A Slag Discharge Outlet On The Small Cone End For Solid Phase Material Discharge, And An Overflow Outlet On The Large End Shaft To Control Liquid Clarity.

● Spiral Pusher

Comprising a cylindrical column section, material accelerator, baffles, spiral blades, and shafts, the spiral pusher's helix is double-ended and left-handed with a hard alloy surface. It connects to the differential and achieves solid-phase material discharge due to speed differences.

● Transmission Mechanism

This includes main and auxiliary motors, hydraulic couplings, belt pulleys, bearings, and a planetary gear differential. The differential is critical and uses a two-stage planetary gear transmission.

● Protective Measures:

To ensure safety, several protective measures are in place:

* Belt pulley-type hydraulic coupling ensures smooth operation and overload protection.

* Torque overload protection safeguards against material blockages.

* An inverter monitors and shuts down the centrifuge in case of overload

2. Installation And Adjustment

▶ Place the main unit on a level surface without the need for anchor bolts.

▶ Ensure ample workspace for operation, maintenance, and repairs.

▶ Adjust the main motor's securing bolts to achieve proper belt tension.

▶ Use the infinitely adjustable overflow plate to modify overflow radius and liquid pool depth as drilling fluid (mud) requirements change.

3. Operation & Use

Pre-Startup Preparation:

→ Check for loose connecting components and obstructions in moving parts.

→ Verify electrical circuit connections.

→ Inspect the differential and hydraulic coupling for oil leaks and ensure proper bearing lubrication.

→ Ensure water and feed valves are closed before starting the machine.

Start Up:

★ Turn on the main power and connect the supply.

★ Activate the "Main Unit Variable Frequency Power Switch" and "Auxiliary Unit Variable Frequency Power Switch."

★ Adjust the "Frequency Conversion/Work Frequency" switch to "Frequency Conversion." ★ Press "Auxiliary Unit Start" to confirm no unusual sounds, then start the main unit.

★ Press "Main Unit Start" and wait for the desired speed before starting the feed pump.

★ Press "Feed Pump Start" to begin material supply.

★ Gradually increase the feed rate, ensuring the current does not exceed 60A. In case of severe vibrations or anomalies, shut off the feed pump, open the water valve, and clean the drum and spiral pusher.

★ Check if the discharge is smooth; if not, clean the slag discharge valve.

Parameter Selection And Configuration:

The control cabinet comes with preset ABB inverter parameters. Adjust speed using the external "Main and Auxiliary Unit Speed Knobs" to control mud density and processing capacity.

For processing mud, adjust the "Main Unit Speed Knob" to manage density. Increase drum speed for higher density or reduce for lower density.

Set the main motor speed based on mud conditions, then adjust the auxiliary motor for desired slag discharge and separation efficiency. Gradually adjust differential speed to prevent tripping. After a fault, reset and press the reset button to restart the machine.

Shut Down:

① Press "Feed Pump Stop" to halt material supply.

② Open the water valve to clean the centrifuge for 10-15 minutes until clear liquid discharges.

③ Press "Main and Auxiliary Unit Stop" buttons to shut down, then turn off the main power.

Products Parameters

Our Factory

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1