LWS series decanter centrifuge is a new type of decanter centrifuge specially designed for extra virgin olive oil and avocado oil production,it contains the latest technology of centrifuge design and production in the world today.The device consists of a horizontal spiral centrifuge,slag discharge device.

The LWS420 Olive Oil Decanter Centrifuge is a high-quality 3 Phase decanter centrifuge designed specifically for olive oil extraction, offering maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology. With a robust design and sturdy quality "Made in China", this centrifuge ensures high efficiency and fast payback time for olive oil producers. The product features a self-cleaning bowl, adjustable machine parameters, and a PLC control panel for simple control and handling, providing customers with a reliable and efficient solution for olive oil extraction.

Team strength is at the heart of the LWS420 Olive Oil Decanter Centrifuge. Our dedicated team of engineers and designers have worked tirelessly to create a product that delivers unmatched performance and quality. With a focus on innovation and precision, our team has developed a centrifuge that is efficient, reliable, and easy to use. From the cutting-edge technology to the meticulous attention to detail, every aspect of the LWS420 reflects our team's commitment to excellence. Trust in our team's expertise and dedication to bring you a product that will exceed your expectations and revolutionize your olive oil production process.

Experience the ultimate in teamwork efficiency with the LWS420 Olive Oil Decanter Centrifuge. This powerful machine is designed to extract the maximum amount of olive oil from your harvest, thanks to its innovative centrifugal technology. The team strength of this decanter lies in its ability to work tirelessly to separate the oil from the pulp, ensuring a high yield with minimal effort. With a strong and reliable team of components working together seamlessly, this decanter guarantees smooth operation and consistent results every time. Invest in the LWS420 Olive Oil Decanter Centrifuge for a reliable and efficient team player in your oil production process.

Product Description

LWS420 Olive Oil Filtering Decanter Centrifuges is designed specially for olive oil extraction from the ready paste by 2-phase or 3-phase separation. Together with our polishing separator,customer can produce the extra virgin olive oil. 2 Phase decanter centrifuge is designed for olive oil extraction to avoid waste water pollution issues. 3 Phase decanter centrifuge is designed for olive oil extraction to get more drier olive pomace.

Plant Benefits:

1.Olive oil lines for batch and continuous processing

2.Design concepts for different capacities

3.Adjustment of machine parameters according to changes in product and process conditions

4.Simple control and handling Robust, sturdy quality “Made in China”

5.High efficiency – fast pay back time

6.Maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology

7.Low fresh water consumption with minimum waste water reduces environmental pollution

8.No manual cleaning of the disc stack thanks to the self-cleaning bowl of the separator

9.Polishing separator for minimum oil losses during discharge and automatic disc cleaning

10.Minimum oil oxidation thanks to centripetal pump 1-2% more oil yield than comparable machines

11.No additional separator needed for waste water because of adjustable paring tube Improved malaxer for high quality olive oil

12.Customer proximity and on-site service due to world-wide sales and service network In-depth know-how: more than 50 years of experience in the development and design of centrifuges.

How To Cultivate The Olive Tree To Extract An Excellent Extra Virgin Olive Oil:

The 5 steps for the production of olive oil

Olive Oil production is mainly divided into 5 phases.

1.Collection

Harvesting is one of the most delicate and decisive steps to obtain an excellent quality olive oil.

Generally it is facilitated with the use of nets lying on the ground under the plants that allow to easily collect the fallenproduct or facilitated by any mechanical equipment.

2.Washing And Pressing

After harvesting the olives are weighed and subjected to an abundant washing in water. This process is carried out with a special washing machine with a constant flow of water that invests the olives.

The crushing system of the milled olives is the most ancient instrument, conceptually derived from the millstones used since the Hellenic age. Today, however, many mills use the most modern hammer crushers, which break the olives by pushing them violently against a metal grid.

3.Kneading

After pressing the olive paste is subjected to the kneading operation which consists of a continuous and slow mixing of the dough.

The kneading phase is an essential moment for the subsequent extraction of the oil from the olive paste. In fact, the kneading allows the olive paste to reach the optimal temperature in which the natural enzymes present are able to fully activate.

4.Extraction

The extraction phase consists in the separation of the oil from the solid fraction.

This phase can be performed for:

* Pressure;

* Centrifugation;

* Percolation.

5.Separation

In this final phase we proceed to separate the olive oil from the water thanks to the centrifugal force.

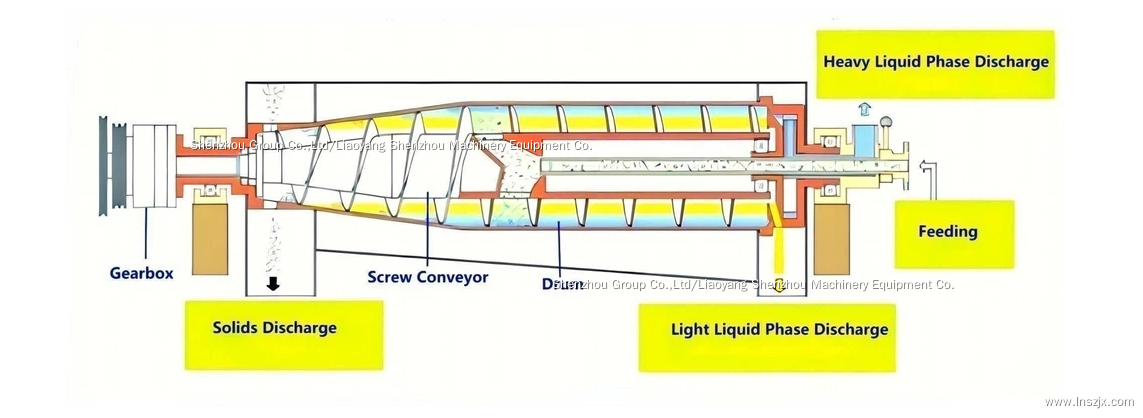

Structure And Working Principle

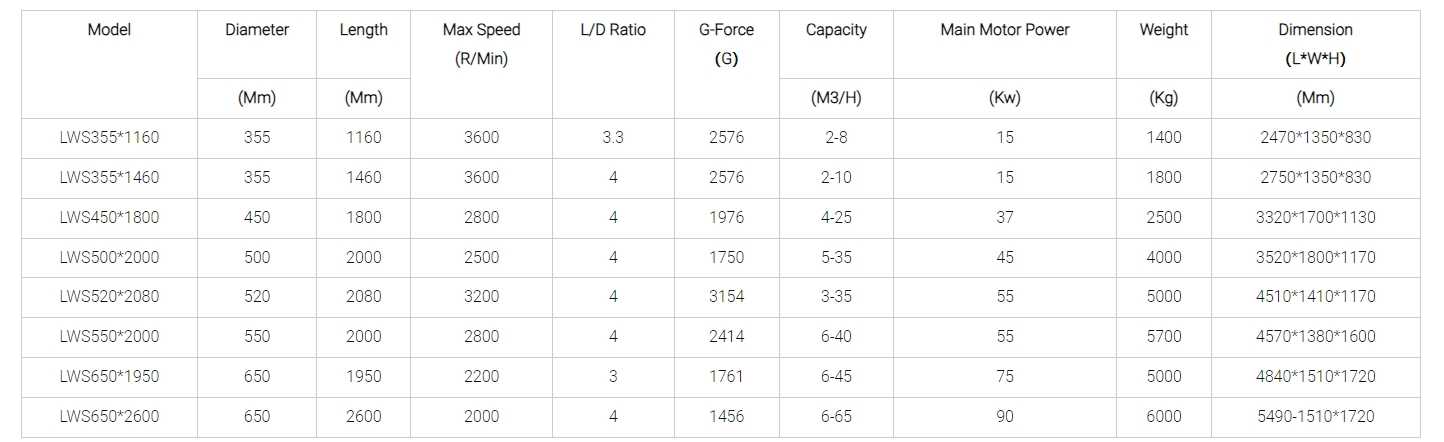

Technical Parameter

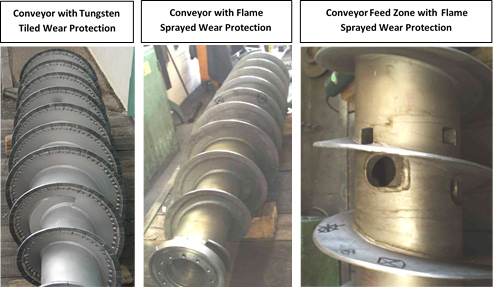

Product Details

Spiral Feeder

The spiral feeder is made of 304 stainless steel, and the forging process is adopted , which can enhance its corrosion resistance.

BD structure, spraying hard alloy powder on the surface of the blade. The thickness is over 3mm .The spiral outlet is equipped

with a replacement hard alloy sleeve, which greatly prolongs the service life of the machine blade. Because of this technology,the maintenance cost of the machine is greatly reduced. Other parts in contact with the material are 304 stainless steel.

Drum

The drum is cast by 304 stainless steel in centrifugal casting, the forging process is adopted , which can enhance its corrosion resistance, The replaceable alloy sleeve is installed in the solid state outlet, so that the mother material of the drum's outlet is not worn, and the wear-resistant bar is installed in the drum to make the drum inside not worn.

PLC Control Panel

The electrical control adopts the double conversion auto control system, which can display the parameters such as frequency, rotation speed, differential speed and current of operating major and auxiliary electrical engine.

Eletrical Components: SIEMENS/Schneider/ABB

Customer Photos

Our Services

Pre-Service

1. 24 hours onlinne consult and service

2. Introduce the product to the customer in detail, answer the question raised by customer carefully;

3. Make different plans for choice according to the needs and requirements of customers;

Sale Service

1. Ensure product with high quality before delivery;

2. Packing and shiping carefully;

3. Delivery on time;

4. Provide full set of documents as customer’s requirements.

After-Sale Service

1. Help to install and debug the equipment;

2. Provide 24 hours techincal support by e-mail or phone;

3. Keep sufficient replaceable spare parts;

4. Help customers slove any other questions about products or other aspect;

5. Establish long-term and friendly relationship.

Hot Tags: olive oil decanter centrifuge, China olive oil decanter centrifuge manufacturers, suppliers, factory, screw press sludge dewatering machine, solids dewatering, avocado oil extraction machine, Tricanter Centrifuge, Avocado And Palm Oil Extraction Centrifuge, Olive Oil Decanter Centrifuge

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1