The LWS horizontal screw centrifuge is a new type of Three-phase horizontal screw centrifuge mainly suitable for three phase separation (oil- water- solid ) of separation plant . It is mainly used in waste motor oil separation; oil sludge treatment, crude oil separation,.

The LWS520 Three Phase Decanter Centrifuge offers superior performance and efficiency when separating solids from liquids in industrial processes. Its advanced design and high-quality materials ensure durability and reliability, making it an ideal choice for demanding applications. With features such as variable speed control and automated operation, this centrifuge provides consistent and precise results for optimal production output.

Team strength is at the core of the LWS520 Three Phase Decanter Centrifuge. With a highly skilled team of engineers and technicians working together, this centrifuge offers unmatched efficiency and reliability in separating liquids and solids. Our team's expertise in design, manufacturing, and customer service ensures that each centrifuge meets the highest standards of quality and performance. By leveraging the collective strength and knowledge of our team, we are able to continuously innovate and improve our products, providing our customers with the best solutions for their separation needs. Trust in the team behind the LWS520 Three Phase Decanter Centrifuge for exceptional results every time.

Team strength is at the core of the LWS520 Three Phase Decanter Centrifuge. With a powerful team of engineers and researchers behind its design, this centrifuge boasts unmatched reliability and efficiency. Our team's expertise in centrifuge technology ensures that this product delivers top performance in separating liquids and solids. The collaboration within our team allows us to continuously innovate and improve the design of the centrifuge, providing our customers with a high-quality and durable product. Trust in the team strength behind the LWS520 Three Phase Decanter Centrifuge for all your separation needs.

Current status:

Currently, there are various types of waste oils, including used motor oil, hydraulic oil, cooking oil, industrial lubricants. Improper disposal or release of waste oils contaminate water bodies, soil, and adversely affect ecosystems. Moreover, waste oils pose health risks to both humans and wildlife. Decanter centrifuges provide a solution for reusing waste oils. This technology enables the separation of oil-water mixtures by utilizing centrifugal force. Decanter centrifuges can effectively separate oil from water and solid impurities. the recovered oil can be further processed and reused. This not only helps in reducing pollution and conserving resources but also provides economic benefits by reducing the need for new oil production.

#waste oil centrifuge for sale#centrifuge for cleaning waste oil;#centrifuge for waste oil;#waste vegetable oil centrifuge;#industrial waste oil centrifuge;#centrifuge waste oil

What is a Decanter Centrifuge

The horizontal spiral centrifuge, also known as a horizontal screw centrifuge, is a type of centrifuge that utilizes a rotating screw conveyor mechanism to separate solid particles or liquid-liquid mixtures based on their density. The centrifuge operates by subjecting the mixture to high centrifugal force, causing the denser components to move towards the outer edge of centrifuge while the lighter components stay towards the center.

It consists of a column cone, spiral discharge device, differential system, bearing seat, base, cover, main and auxiliary motors,and electrical system. It is capable of separating materials ranging from 0.002 to 5um. This tricanter centrifuge is commonly used in various industries such as chemical, pharmaceutical, food processing, and wastewater treatment.

It offers advantages such as 24 hours continuous operation, high separation efficiency, and the ability to handle large volumes of feed material. Horizontal spiral centrifuges are particularly effective separating fine particles or emulsions with a narrow density difference.

The LWS520 centrifuge allows for adjustable parameters to optimize the separation process. Parameters such as rotation speed, differential speed, and liquid level can be adjusted to suit the specific characteristics of the oil being processed. Fine-tuning these parameters improves the separation efficiency and product quality.

How Does Decanter Centrifuge Works

2 phase Centrifuge working principle:

After entering into the high-speed turning drum, the solid-phase particles in the mixed liquid run and settle on the drum wallunder the action of greatest centrifugal force; the light liquid settles at the innermost place of the drum under minimum centrifugal force; same as the drum's turning direction, a screw feeder also turns at a high speed, and a constant speed difference is generated by the differential mechanism, then the liquid will be discharged by the liquid outlet.(solid-liquid separation)

3 phase Centrifuge working principle

Three-phase centrifuge is that two liquid phases and one solid phase enter the centrifuge and expand it thousands of times by relying on the centrifugal force field. The solid phase is settled under the action of centrifugal force, and the two liquid phases are also stratified, so as to realize Solid-liquid-liquid 3-phase separation and discharge them from the body under the action of special mechanism. The whole feeding and separation process is continuous, closed and automatic. (solid-liqui-liquid separation)

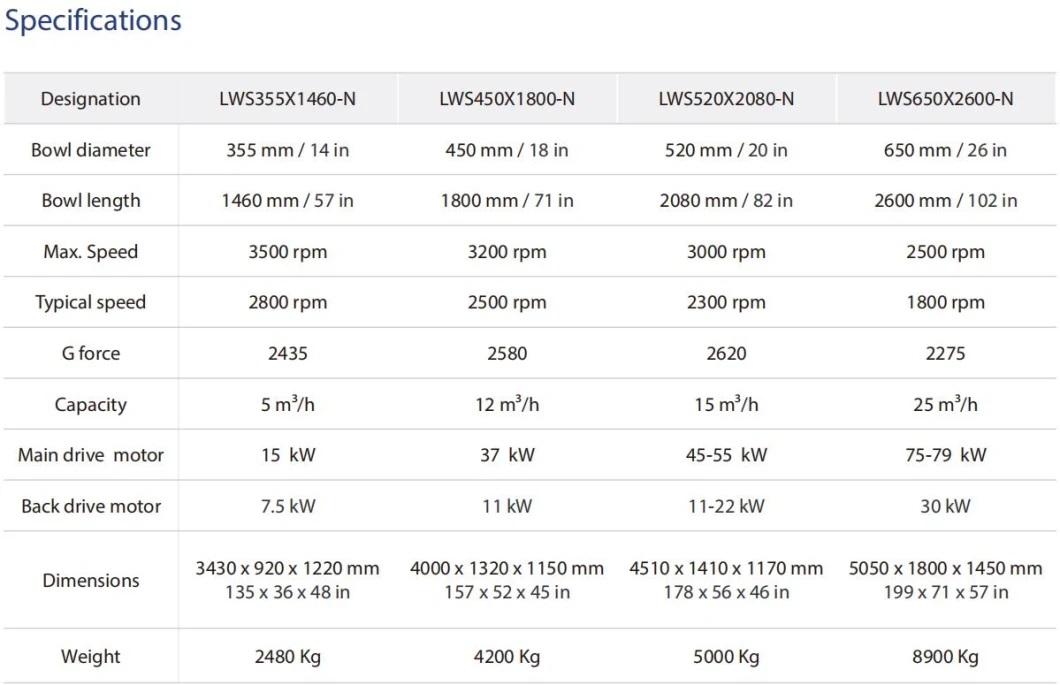

PRODUCT SPECIFICATIONS

Product Parameters:

Application:

Shenzhou LWS 520 Waste Oil Decanter Centrifuge : High G Force up to max 3000.

Big Volume Design. Bowl Material Duplex Stainless Steel 2205 made from centrifugal casting. Conveyor Wear Surface: Tungsten carbide tiles .The life is much longer than hard surface. And all tiles is interchangeable for easy maintenance.

Preasurized Explosiong Proof with PLC and HMI control for automatical operation. All the bearings for the centrifuge are S-KF brand premium bearings. Shenzhou LWS 520 Centrifuge for Drilling Waste Management: The drilling fluids recovered by the drilling cuttings dryer should go through the GNLW363 decanter centrifuge to reduce the solids content before returning to the active mud system.

The LWS three phase decanter centrifuge can be used in WBM, SBM or OBM. LWS 520 Dewatering Centrifuge for water based drilling waste: The result is a polymer enhanced flocculation of colloidal and ultra-fine drilled solids that can be efficiently removed with LWS decanter dewatering centrifuge. Without such a system, operators, would be left with the accumulation of colloidal and ultrafine drilled solids in the mud system. Ultimately leading to excessive mud densities, pipe torque/drag, mud loss, disposal fees, and overall well cost. Shenzhou LWS 520 Centrifuge for Oil Sludge Treatment: The design of the centrifuge on the telescopic skid is popular for oil sludge separation, and waste management rental business. The telescopic skid height is adjustable, It allows the liquid discharged from the centrifuge goes to storage tank by gravity without a transfer pump.

Features

* Adjustable bowl speed via VFD

* Highest g-force for higher solids output

* Approximately 80 to 90 % of the oil is recovered.

* Belts for both primary motor and secondary motor

* Automatic adjustment of differential speed via VFD

* Low personnel costs due to continuous and automatic operation.

* 3-phase AC motor for controlled torque starting via frequency converter

* All parts coming into contact with the product are made of stainless steel.

* Differential with high precision, compact structure, smooth operation.

* Main bearing of imported bearings, to ensure the accuracy of the operation.

* The machine is equipped with a variety of safety overload protection devices, to make sure safety in production.

* The machine system has two types, regular and explosion proof, to meet the different requirement.

* Large length to diameter ratio, high speed, many angels of drum cone structure

* Spiral pusher surface adopts hard alloy materials, against abrasion powerfully

* According to the customer's desire, the frame can develop to low center of gravity, high bracket and move.

* Spiral structure with BD board is used for the concentration dehydration of activated sludge and difficult separate materials

Successful Project

Material Choice

According to users' requirement,the product contact parts can be made of austenite stainless steel (321,316L...904L,C2205),Haynes alloy titanic alloy or other anti-erosion materials!

We Are The Earliest Centrifuge Manufacturer In China

Shenzhou Machinery is a subsidiary of Shenzhou Group.Which was Established In 1980, conveying an Area Of 80000M2 ,there are 2500 Staffs and employee in our company.200 of them are technicians and engineers.It has obtained the approvals and certifications of both CE and ISO.

Some of our machines gained the new technology invent patent. We are on of the world's leading manufacturers of decanter centrifuge,disc centrifuge,tubular centrifuge,separation systems and drying equipment. now there are over 180 series or decanter centrifuges and disc separators used home and abroad.Including U.S.A , Canada ,Australia,Russia ,Brazil,Singapore and so on totally 70 Countries.

We own various kinds of inspection and testing facilities with value Over USD10 Millio, We also welcome OEM and ODM orders.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Chemical&Pharmaceutical Centrifuge and an unforgettable experience of partnering with us.

The buyers of three phase decanter come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. three phase decanter QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the three phase decanter, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing three phase decanter organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1