Horizontal Separator Screw Three Phase Decanter Centrifuge for Olive Oil

Industrial decanter separator centrifuge machine for olive oil extraction from the ready paste by 2-phase or 3-phase separation. Together with our polishing separator,customer can produce the extra virgin olive oil.

2 Phase decanter centrifuge is designed for olive oil extraction to avoid waste water pollution issues.

3 Phase decanter centrifuge is designed for olive oil extraction to get more drier olive pomace

Plant Benefits:

1.Olive oil lines for batch and continuous processing

2.Design concepts for different capacities

3.Adjustment of machine parameters according to changes in product and process conditions

4.Simple control and handling Robust, sturdy quality "Made in China"

5.High efficiency - fast pay back time

6.Maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology

7.Low fresh water consumption with minimum waste water reduces environmental pollution

8.No manual cleaning of the disc stack thanks to the self-cleaning bowl of the separator

9.Polishing separator for minimum oil losses during discharge and automatic disc cleaning

10.Minimum oil oxidation thanks to centripetal pump 1-2% more oil yield than comparable machines

11.No additional separator needed for waste water because of adjustable paring tube Improved malaxer for high quality olive oil

12.Customer proximity and on-site service due to world-wide sales and service network In-depth know-how: more than 50 years of experience in the development and design of centrifuges.

How to cultivate the olive tree to extract an excellent extra virgin olive oil:

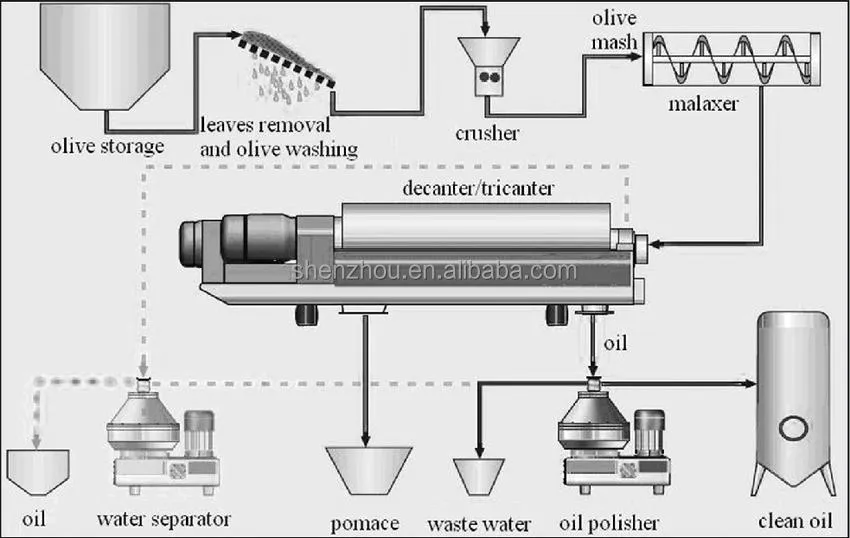

The 5 steps for the production of olive oil

Olive Oil production is mainly divided into 5 phases.

1.Collection

Harvesting is one of the most delicate and decisive steps to obtain an excellent quality olive oil.

Generally it is facilitated with the use of nets lying on the ground under the plants that allow to easily collect the fallen

product or facilitated by any mechanical equipment.

2.Washing and pressing

After harvesting the olives are weighed and subjected to an abundant washing in water. This process is carried out with a special washing machine with a constant flow of water that invests the olives.

The crushing system of the milled olives is the most ancient instrument, conceptually derived from the millstones used since the Hellenic age. Today, however, many mills use the most modern hammer crushers, which break the olives by pushing them violently against a metal grid.

3.Kneading

After pressing the olive paste is subjected to the kneading operation which consists of a continuous and slow mixing of the dough.

The kneading phase is an essential moment for the subsequent extraction of the oil from the olive paste. In fact, the kneading allows the olive paste to reach the optimal temperature in which the natural enzymes present are able to fully activate.

4.Extraction

The extraction phase consists in the separation of the oil from the solid fraction.

This phase can be performed for:

* Pressure;

* Centrifugation;

* Percolation.

5.Separation

In this final phase we proceed to separate the olive oil from the water thanks to the centrifugal force.

If you want to know more please contact me:Cathy Tel:+8613130722088(WhatsApp)

Website: www.lnszjx.com