Sludge Dewatering Horizontal Type Spiral Centrifugal Machine For Industrial And Domestic Sewage Treatment Horizontal Screw Centrifuge

Applied in our manufacturing process, the technologies have speeded up the whole process and guaranteed the product quality.In the application range(s) of Water Treatment Machinery,Sludge Dewatering Horizontal Type Spiral Centrifugal Machine for Industrial and Domestic Sewage Treatment is of great use.

The Spiral Centrifugal Sludge Dewatering Machine for Sewage Treatment is designed to effectively remove moisture from sludge, resulting in reduced volume and easier disposal. Its high-speed rotating screw shaft efficiently separates water from solids, making it an ideal solution for wastewater treatment plants. With its compact design and high dewatering performance, this machine saves both space and energy, ensuring cost-effective and sustainable sewage treatment processes.

At our company, we specialize in producing high-quality Spiral Centrifugal Sludge Dewatering Machines for sewage treatment. With years of experience in the industry, we are dedicated to providing efficient and reliable solutions for wastewater management. Our machines are designed to effectively remove moisture from sludge, reducing volume and minimizing disposal costs. We pride ourselves on our commitment to innovation and sustainability, ensuring that our products not only meet but exceed industry standards. Trust us to deliver top-notch equipment that will make a significant impact on your sewage treatment processes. Choose our company for all your sludge dewatering needs.

As an e-commerce product operation expert, I would focus on highlighting the company's expertise and commitment to providing innovative solutions for sewage treatment. With a strong emphasis on sustainability and efficiency, our Spiral Centrifugal Sludge Dewatering Machine is designed to effectively remove excess water from sludge, reducing environmental impact and costs associated with sewage treatment. Our company is dedicated to continuous improvement and customer satisfaction, striving to meet the highest standards in the industry. Trust in our reliable and high-quality products to meet your sewage treatment needs effectively.

Product Description

Horizontal type spiral precipitated centrifugal machine is called horizontal type spiral centrifugal machine for short. lt is a high efficiency horizontal type spiral centrifugal equipment for discharging and precipitation. Generally, it can be divided into horizontal type spiral filtering centrifugal centrifugal machine and horizontal type spiral pricipitated centrifugal machine. lt is widelly used for dehydration for the sludge in industrial and domestic sewage, besides, it is also used in pharmaceutical factory, chemical industry and food-making industry.

Application

|  |

| Characteristics 1. low power consumption 2. large handling capacity 3. automatic running 4. 24 hours continuous operation 5.High corrosion resistance 6.Reliable safety guard |

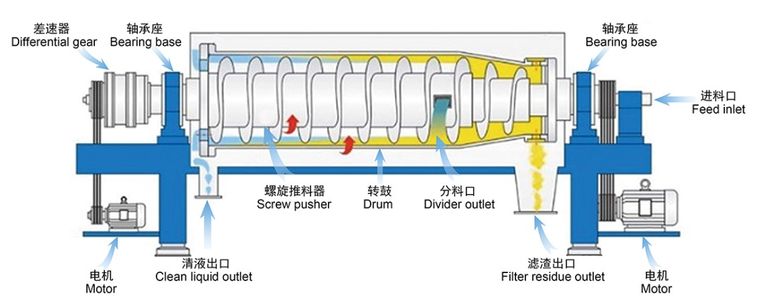

Horizontal Decanter Centrifuge is mainly composed of a conical drum, screw pusher, differential system, bearing base, frame, housing, main and auxiliary motor and electrical system. The main motor drive the drum and the second motor drives the planetary gear differential, which generates the drum and spiral differential. Under the strong centrifugal force produced by the high-speed rotation, the centrifuge can be separated continuously.

The drum and the screw pusher rotate at a certain differential speed and high speed. The material continuously enters the feeding tube's spiral feeding chamber and then accelerates and enters the drum. Under the centrifugal force field, the heavier solid phase deposits on the drum wall to form the sediment layer.

The solid deposits are continuously pushed to the drum's cone end by the screw pusher and discharged from the slag discharge outlet after drying in the drying zone. The lighter liquid phase forms an inner liquid ring, which continuously overflows the drum from the overflow outlet at the drum's large end and discharges out of the machine through the outlet.

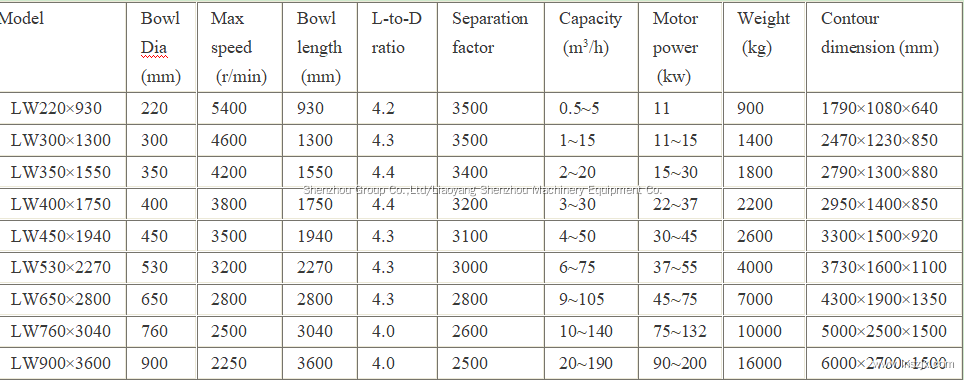

Technical Parameters:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1