The three phase centrifuge for efficient waste oil recovery utilizes high G force of over 3000 G and offers flexibility with various scroll and bowl wear protection systems. This decanter centrifuge features a duplex stainless steel bowl for corrosion resistance and VFD control with HMI and PLC for automatic operation. With the ability to separate water and sludge from waste oil while providing customized design options, this centrifuge is a valuable asset for industries dealing with waste oil recovery.

Our Company Profile

At our company, we are dedicated to providing innovative solutions for efficient waste oil recovery. With a focus on sustainability and environmental responsibility, we have developed a cutting-edge Three Phase Centrifuge that delivers superior performance in separating oil, water, and solids. Our team of experts works tirelessly to ensure that our products meet the highest quality standards and provide our customers with reliable and cost-effective solutions for their waste oil management needs. With a commitment to excellence and customer satisfaction, we are proud to be at the forefront of the industry, offering state-of-the-art solutions for a greener tomorrow.

Our company is a leading manufacturer and supplier of innovative industrial equipment, including the Three Phase Centrifuge for Efficient Waste Oil Recovery. With a strong emphasis on quality and efficiency, we aim to provide our customers with top-of-the-line products that meet their unique needs. Our team of experts is dedicated to continuous improvement and technological advancements, ensuring that our products are at the forefront of the industry. We prioritize customer satisfaction and are committed to delivering exceptional service and support, making us the go-to choice for businesses looking to streamline their waste oil recovery processes.

3 phase decanter specially used for separate water and sludge from waste oil,then get clear oil.More details please check following:

Products Description

The waste oil recovery and treatment include following:

Oil storage tank bottom solids and water and oil

Oily residues, slop oils from oil refineries

Oil sludge lagoons

Oil water mixtures from ship ballasts

API oil water separator sludge treatment

Industry discarded lubricant oils and emulsions

Industrial oil / water and emulsion waste streams

Advantage of Waste Oil Recovery decanter centrifuge

More sizes available with big length/diameter ratio of 4.2:1 or greater.

High G force up to over 3000 G.

Two phase or 3 phase separation decanter is available.

Nitrogen purged centrifuge for explosion proof.

Duplex Stainless Steel bowl for Corrosion resistant materials

VFD control with HMI and PLC for automatically operation.

Variable bowl speed, differential speed, and adjustable pump capacity for the system.

Various scroll and bowl wear protection systems by tungsten carbide materials.

Customized design with flexibility according to clients requirements.

Worldwide partners and branches to offer you fast support for your waste oil recovery.

Depends on customer's requirements for the source of the waste oil and make-up of the raw material as well as the quality of the products after processing. The selection of equipment and process will be different, but a typical waste oil processing plant will include following.

Separation of solids from the waste oil.

Reducing the viscosity by using chemical or heating.

Breaking the emulsions and make oil, water and solids bound in the emulsion accessible by de-emulsifier dosing for decanter centrifuge separation.

Polymer dosing dewatering to improve the separation efficiency.

Shenzhou Protein Isolation Decanter Features And Benefits

1. Industrial Design

Whole machine set design follows concept of advanced industrial design,ensures stability, functionality and safety of whole machine.

2. High Rigidity Screw Rotor

The decanter centrifuge is a typical high-speed rotating device with dual rotors. In the protein industry, it boasts a separation factor of up to 2370G, characteristic of high-speed centrifuges. Ensuring operational stability, the rigidity of the rotor and control of unbalance are vital factors. The Shenzhou centrifuge is meticulously designed in compliance with JB/T 8051-2008 centrifuge drum strength calculations. The screw rotor, adaptable to high-speed conditions, undergoes finite element modal analysis to steer clear of first and second-order critical speeds, preventing high-speed resonance. This safeguards bearing longevity, reduces vibration, and minimizes noise levels.

3. Bubble Breaker

At the acid-sinking section, the high-speed centrifuge will produce a large number of bubbles in the separation and liquid discharging processes. If the bubble is not broken, it is hard to take out protein. Shenzhou protein isolation decanter is internally set with a bubble breaker, which plays a good role.

4. Discharge Device For Centripetal Pump With Pressure

In the centrifuge's drainage process, the formation of bubbles can often lead to drainpipe blockages, resulting in fluctuations in the centrifuge's operating current. The Shenzhou protein isolation decanter features an integrated pressure-enabled centrifugal pump discharge device, which prevents the high-speed ejection of supernatant. This device is especially well-suited for scenarios where the liquid phase is directly transferred to subsequent equipment or processes after separation. For instance, in the protein separation process, when soybean milk from the first and second extractions proceeds to the acid precipitation tank, the use of this device eliminates the need for intermediate transition tanks, transfer pumps, and associated pipelines and instrumentation.

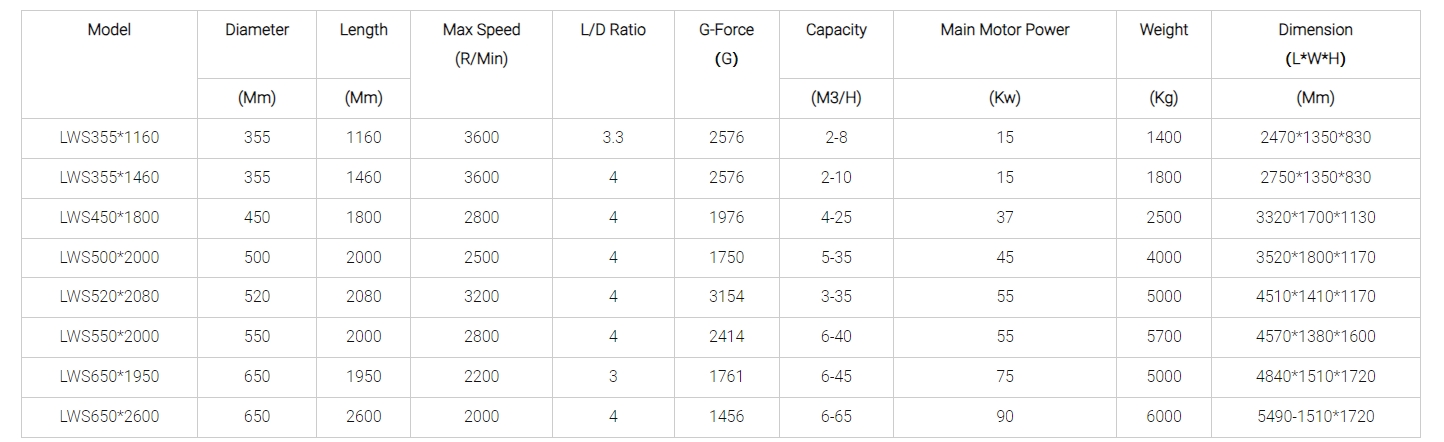

Technical Parameter

Our Customers

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1