Our Three Phase Decanter for Palm Oil Processing is designed with precision engineering to separate oil, water, and solids efficiently. With high-quality materials and advanced technology, this decanter ensures a smooth and continuous palm oil production process. Its innovative features include a robust design, easy operation, and low maintenance, making it a reliable and cost-effective solution for palm oil processing.

Team strength is a crucial component in the successful operation of our Three Phase Decanter for Palm Oil Processing. Our team of experts brings together a wealth of knowledge and experience in the palm oil industry, ensuring that our decanter is designed and manufactured to the highest standards. From our engineers who work tirelessly to develop innovative solutions to our customer service team who provide unparalleled support, our team is dedicated to providing top-quality products and service. With a focus on collaboration and ingenuity, our team strength is evident in every aspect of our decanter, making it a reliable and efficient choice for palm oil processing.

Our Three Phase Decanter for Palm Oil Processing is a testament to our team's strength in creating innovative and efficient solutions for the agricultural industry. With years of experience and expertise in palm oil processing, our team of engineers, technicians, and researchers have collaborated to design a high-performance decanter that guarantees maximum oil extraction and purity. Our dedication to quality and customer satisfaction drives us to continuously improve and perfect our products, ensuring that our customers receive the best results possible. Trust in our team's strength to deliver exceptional performance and reliability in palm oil processing.

Palm Oil Extraction

Product Description

Palm oil is one of the most produced oils in the world. The global demand for palm oil is overgrowing. The traditional manual crushing method for extracting palm oil can no longer meet the palm oil market's needs. The three-phase decanter centrifuge provides an effective separation and purification program for palm oil processing plants' processing process. It can help palm oil mills process fresh palm fruit bunch (FFB) into crude palm oil (CPO), with the characteristics of high efficiency and high purity. Simultaneously, the equipment can work automatically and continuously for a long time, which can significantly improve the refining efficiency of palm oil. In the process of palm oil extraction, the palm oil decanter is used for: Direct processing of the crude oil after the screw press; Oil recovery from empty fruit bunch liquor; Crude oil recovery from the sludge in the CS tank; Crude oil recovery from the wastewater flow of the palm oil mill.

SEPARATION Decanters for Palm Oil Production Process

SHEENZHOU is a company that manufactures and develops different types of centrifuge equipment for all walks of life. For the palm oil separation and purification process, SZ has specially designed a food-grade palm oil three-phase centrifuge to realize the automatic separation and extraction of palm oil and the oil recovery from the sludge. In addition, SZseparation has a mature production technology that allows better results of separation which refers to less water consumption, less waste disposal, fewer costs, and more oil. SZcentrifuge adopts a frequency converter to control all operating parameters of the machine. Whether when running at a high speed or in the discharging process, it can significantly reduce the vibration and noise level during operation.

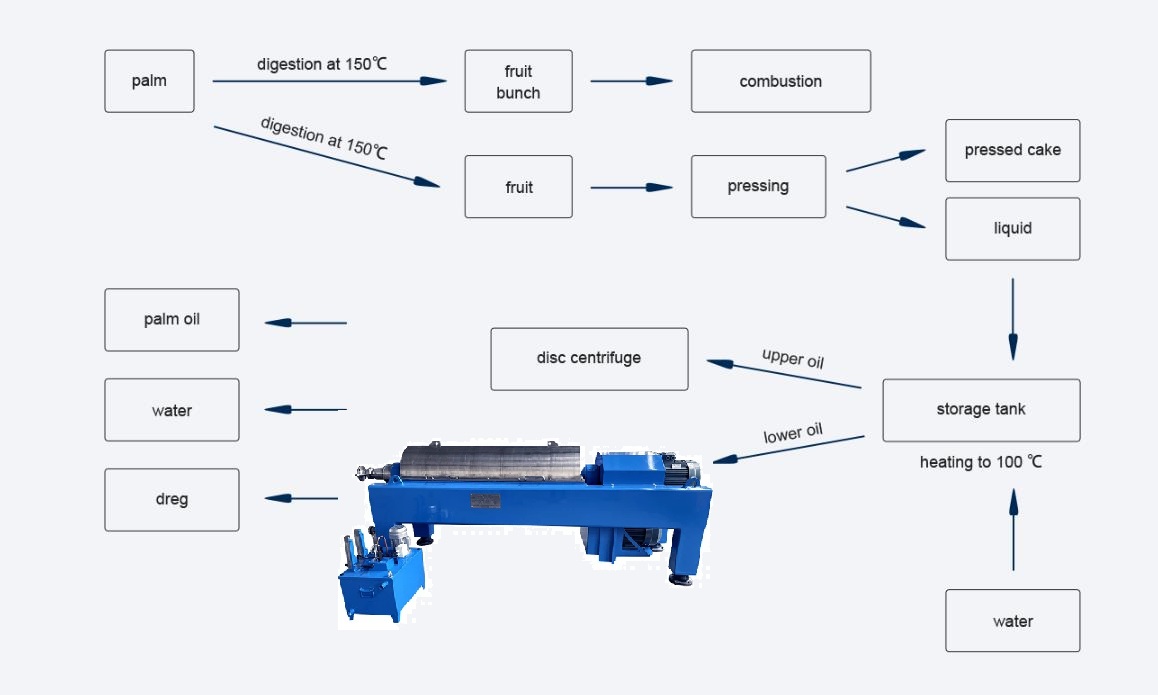

Oil palm processing process

Firstly, the fresh fruit bunches are sent to the preliminary pressing factory within 24h after harvesting (mainly to prevent the increase of FFA).

Then, the fruit bunches are heated to 150℃ and keep the temperature for 85min to sterilize the fruits and boil out the stalks.

The fruits then are separated from bunches by winder – peeling machine. After that, bunches can be used for combustion and fruits are introduced to silo.

Next, send the fruits into a screw press for high-pressure pressing. The pressed cake containing kernel (unbroken, containing palm kernel oil) is squeezed out from the machine head, and the liquid (mainly palm oil) is discharged from the liquid outlet of the presser.

The liquid is discharged from the outlet to a 100m³ tank, and be heated by water (maximum 100°C). After standing for a while the upper raw palm oil in the tank is directly discharged into the three-phase disc centrifuge to be separated; and the lower water containing palm oil would be separated in the 3 phase decanter (oil +water+ dreg).

Finally, the palm oil separated in the three-phase decanter is sent to a 100m³ tank again for standing and extraction of raw palm oil.

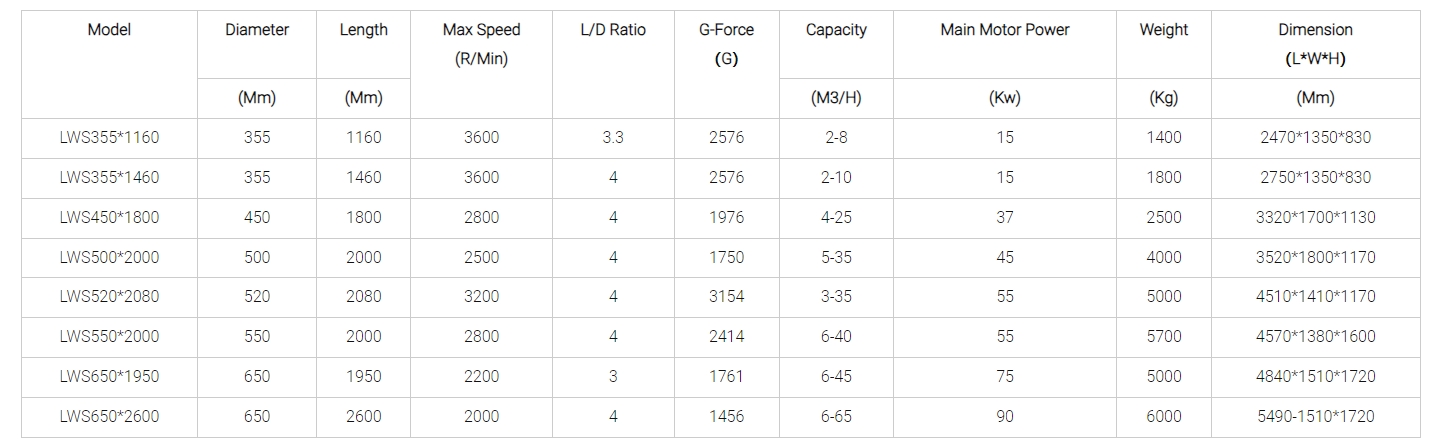

Product parameters from Shenzhou decanter

Our Customers

Shenzhou decanter pacakge:

Regarding the attributes and functionality of the three phase decanter, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of three phase decanter come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. three phase decanter QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing three phase decanter organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1