The horizontal spiral centrifuge produced by Shenzhou Group is specially used for the separation of river sludge. The separated sludge can be directly incinerated.

Brief Introduction

LW Sedimentation Centrifuge from Shenzhou Group is a horizontal, continuously working and continuously spiral discharging sedimentation centrifuge. It is used in a variety or industries for separating all kinds of solid liquid suspension, defecating liquid phase with graded grains, and dehydrating sludge such as: polyoxyethylene, sulfurous acid tansuanbei, strontium sulfate, lidefen, titanium pigment, ore porcelain, clay, kaoline, diatomite, amylum, soyabean protein earthnut protein, syrup, beverage, vegetable oil, citric acid scavenge oil purification, cleansing water purification, lees, tallow, blood powder, sludge from power plants, sludge from printing and dyeing, sludge from paper making, sludge from desulfurizing natural gas, calcium carbide sludge, activated sludge ammonia sludge, sludge from washing cars, alum sludge, drilling mud, coal flotation waste, cryolite flotation liquid.

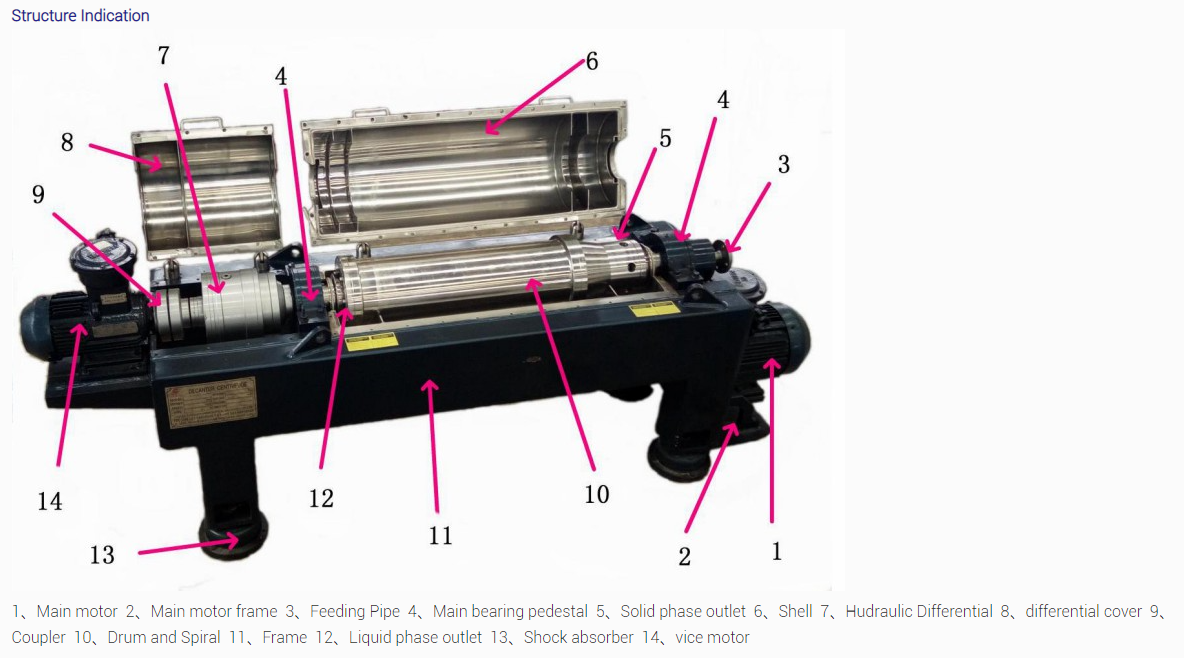

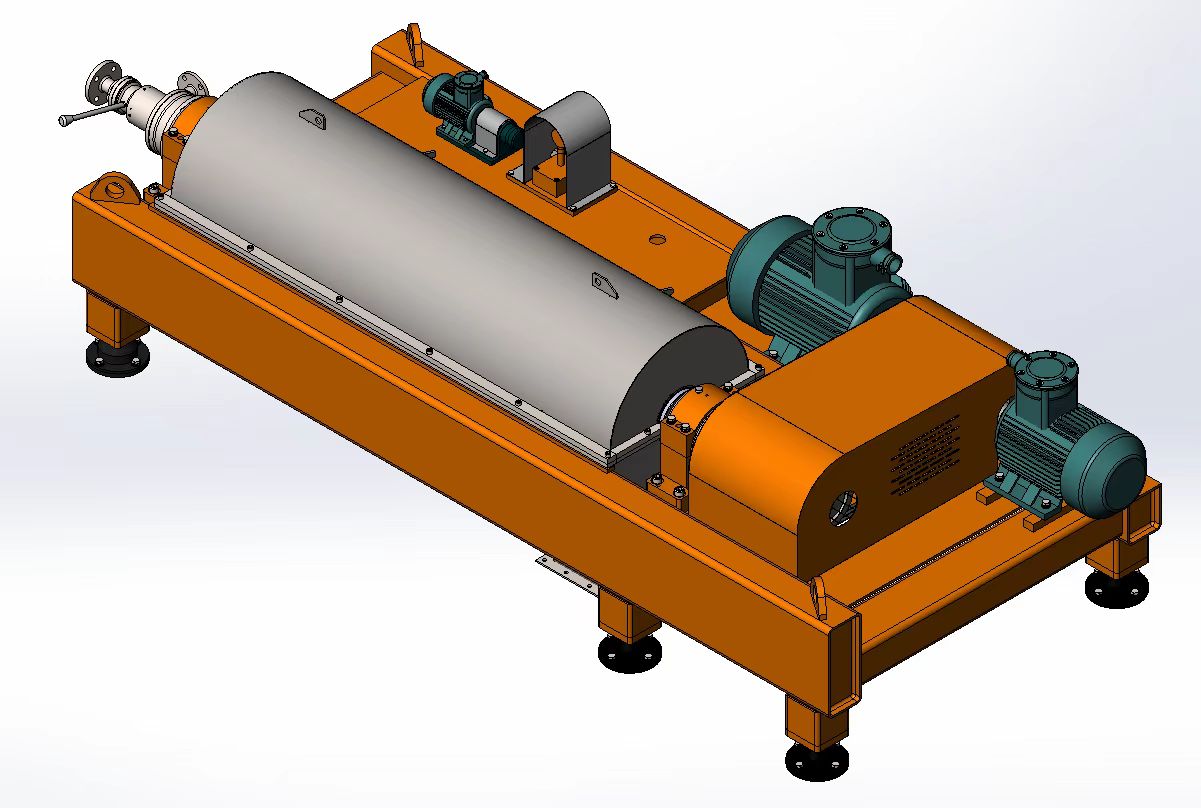

This machine is a countercurrent horizontal spiral discharging and settling centrifuge (horizontal screw centrifuge or centrifugal dehydrator for short), and the main machine is composed of column and cone drum, spiral discharging device, differential, bearing seat, frame, housing, main and auxiliary motors, and electrical system.Its working principle is: the suspension after the feed pipe and spiral discharging mouth into the drum, under the effects of the centrifugal force at high speed, high proportion of solid phased particles deposited on the inner wall of the drum, the drum for relative motion of the helical blade will continuously of solid phased particles deposited on the drum wall scraping, spiral pusher of solid phased particles will scrape the specially designed the structure of the two-way extrusion.

Description of Main Parts

Drum Parts:

● drum adopts centrifugal casting or forging, choose stainless steel material according to the material properties, choose 2205 duplex stainless steel;

● drum parts of castings, welding parts and forging after high temperature heat treatment process (solid solution treatment), effectively avoid the intergranular corrosion of stainless steel organization and delta facies tended to defect, improve the organizational structure and corrosion resistance of the weld area, can fully eliminate the casting, welding, forging stress and processing residual stress;

● drum parts of castings, welding parts and forgings according to standard JB/T9095 and technical specification of JB/T10411 NDT inspection and acceptance

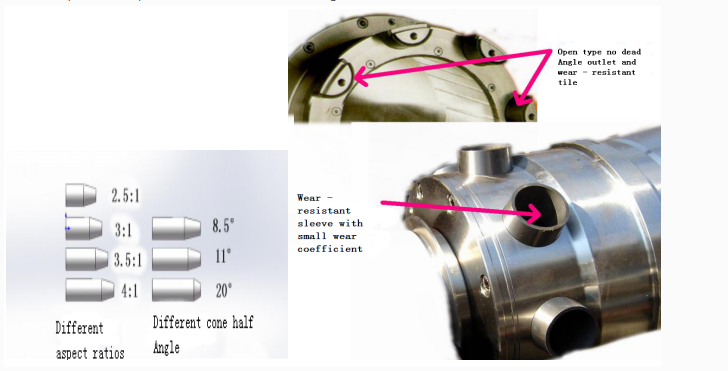

2. Spiral Discharger Components:

● spiral blade is made of stainless steel sheet suppression and become, after extrusion, due to the existence of the surface compressive stress, strength and wear performance is greatly enhanced, not easily by pushing torque deformation;

● spiral feeding port and the location of the blade pushing part, such as easy to wear according to material features with spray hard tungsten carbide, tungsten carbide hardness of the coating is HRA65 ~ 68, the high hardness reduces the material of the spiral wear and improve the service life of the screw;Stainless steel 316L is selected for other parts and parts of the screw according to material characteristics.

3. Bearing Block Components:

● parts according to the material characteristics of bearing parts contact with material choose stainless steel material, other parts made of high quality carbon structural steel and alloy steel;All bearings are of international brand (NSK or SKF or FAG);

● thin oil circulation is used in the main bearing lubrication, to guarantee good lubrication of the bearing, the equipment safe and reliable operation, easy to operate;Spiral bearings are lubricated with grease (mobil EP2);

● lubrication system of the machine set including the oil pump motor, oil pump, oil filter, pressure gauge, etc., cut-off protection: lubricating pump if abnormal centrifuge automatic alarm downtime, restore power machine can't start, when the power must be started manual intervention, and set the permissions;

Advantages:

· · Increase mud separation percentage

· Continuous operation without interrupt

· Save power 15-30%

· Save wear cost.

• Mud concentrated

Working principle:

Suspension liquid goes into the drum through the feeding tube and spiral screw

Then through the centrifugal force produced by high-speed rotary machine, the heavier density solids will gather on the inside rotary drum wall

Helical screw which is rotary in differential speed with the rotary drum, continuously scrap and push the solids to slag

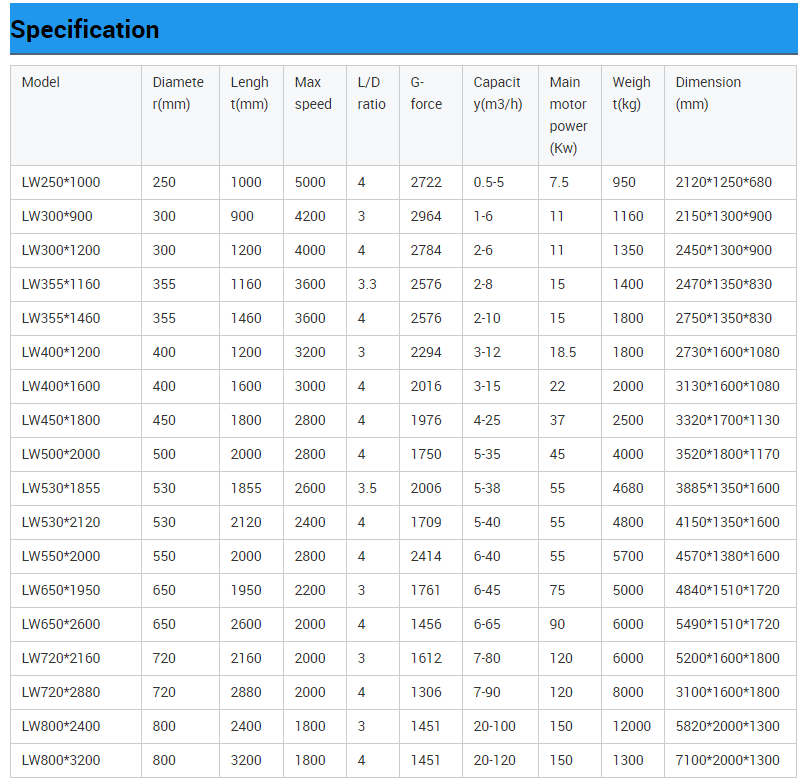

Technical Parameter:

Package show:

Export fumigation-free wooden box packaging to meet the packaging requirements of various countries!

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1