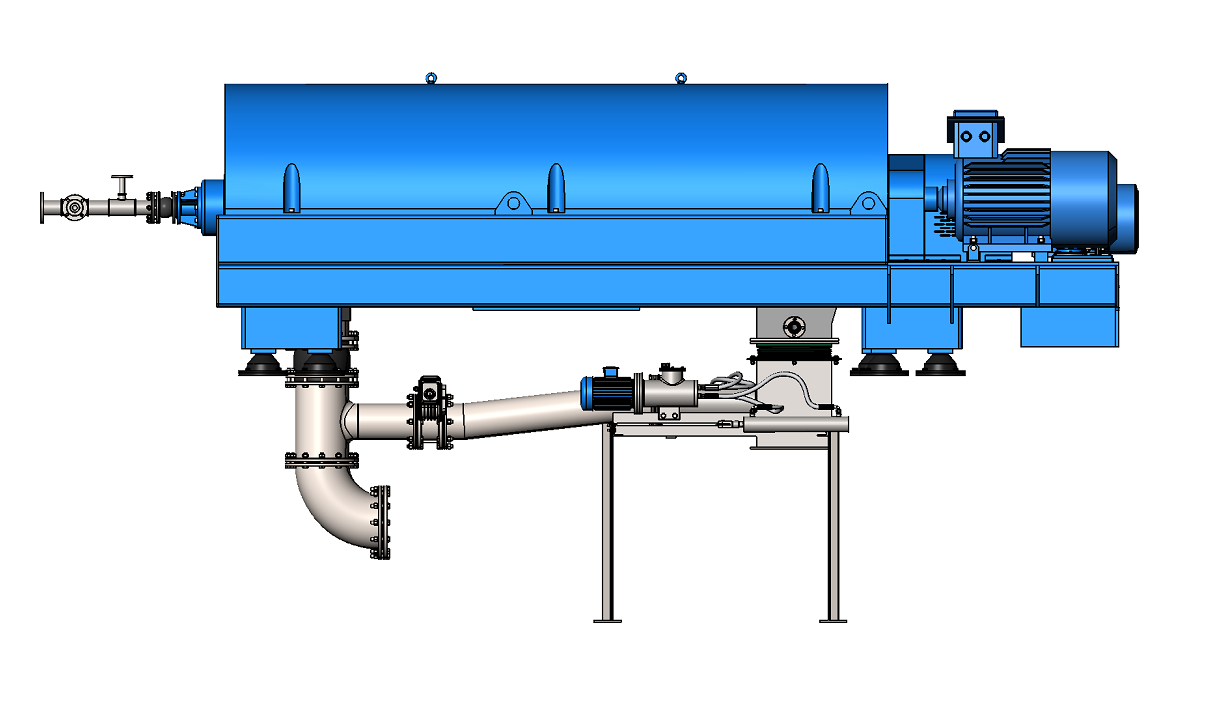

The decanter centrifuge for the thickening of sewage sludge:

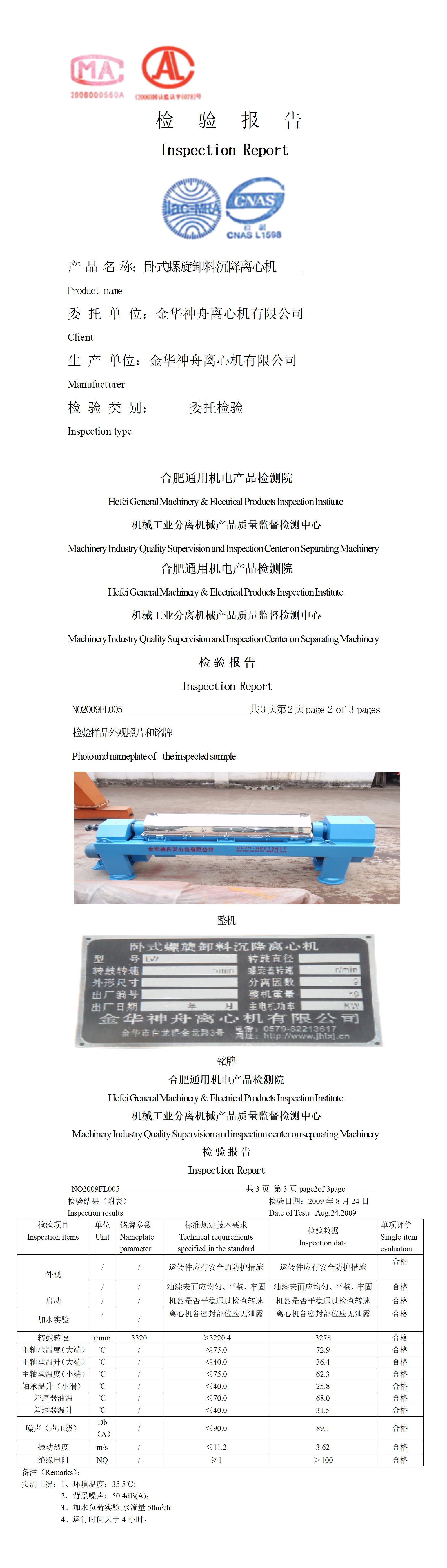

LW760 Decanter centrifuge from Shenzhou Group specially used for thickening of sewage sludge.

Sludge thickening decanter from Shenzhou :In the process of treating waste water, fine biological sludge is constantly produced during the decomposition process at a sewage treatment plant. For a stable decomposition process in the biological treatment phase, the sludge produced in the secondary sedimentation pond, also known as excess sludge, is removed and fed into the digestion tower. Shenzhou LW decanters thicken the sludge before it enters the digestion tower. Sewage treatment plants benefit from an even feeding of the digestion tower and can thus optimally use the volume of the digestion tower. The LW decanter is specially designed for sludge thickening. Thus this thickening centrifuge achieves considerably better separation qualities than other centrifuges.

More than 50 years of experience and know-how in the field of sewage sludge thickening flow into our decanters. The thickening decanter is thus convincing in terms of reliability, high economy and minimum maintenance.

Reduce cost of sludge dewatering and sludge thickening:

Depending on the size of the waste water treatment plant, different waste water treatment processes are used. Sewage plant operators use Flottweg decanter centrifuges at various stages of waste water treatment to dewater and thicken sewage sludge. Sludge dewatering and thickening reduce the volume of sludge produced. After the sewage sludge is dewatered with a decanter, it can be reused or disposed of in various ways, such as agricultural use, incineration or landfill.

Thanks to decades of experience and consistent further development, SHENZHOU achieves an optimum dewatering rate for each type of sludge. This leads to considerable savings in transport and disposal costs.

Technical paramter of LW760 Sludge thickening decanter from Shenzhou :

No. | Item | Specification | Remark |

| 1 | Bowl Diameter (mm) | 760 | |

| 2 | Bowl Length (mm) | 3040 | |

| 3 | Bowl Shape | Cylinder-Cone | Hard alloy solid discharge ports |

| 4 | Wedge slope | 2 × 8° | |

| 5 | Bowl speed (r/min) | 2700 | |

| 6 | Relative Centrifugal Force | 1360 | |

| 7 | Scroll Conveyor | Scroll flights lined with tungsten carbide had alloy Hard alloy solid discharge ports | Single end, Left cycle rotating |

| 8 | Gearbox | Planetary Gearbox | |

| 9 | Differential Speed(r/min) | 1~30 | |

| 10 | Main Motor(kW) | 110 | IP55 |

| 11 | Back drive motor(kW) | 37 | IP55 |

| 12 | Pond Depth mm | Adjustable | |

| 13 | Overall Dimension (L*W*H ) mm | 5630×1900×1520 | |

| 14 | Machine weight | 9200kg |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1