Feature of tubular centrifuge separator

The tubular centrifugal separation machines has high performance of separate factor, high capacity, and account for small area and easy to handle.

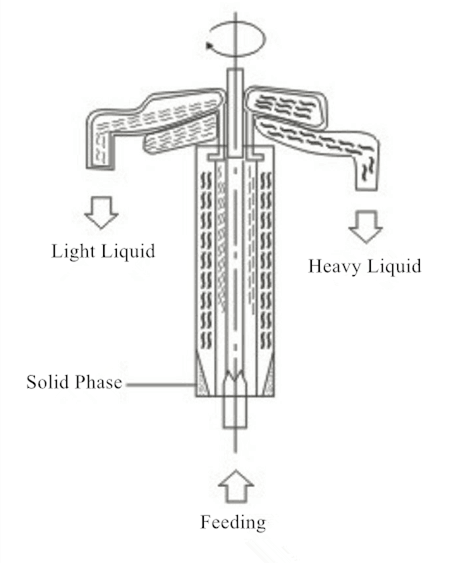

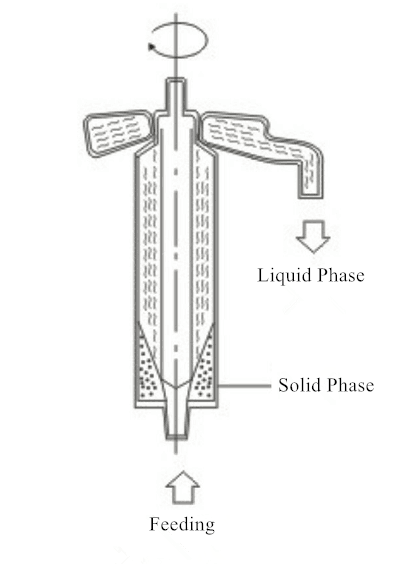

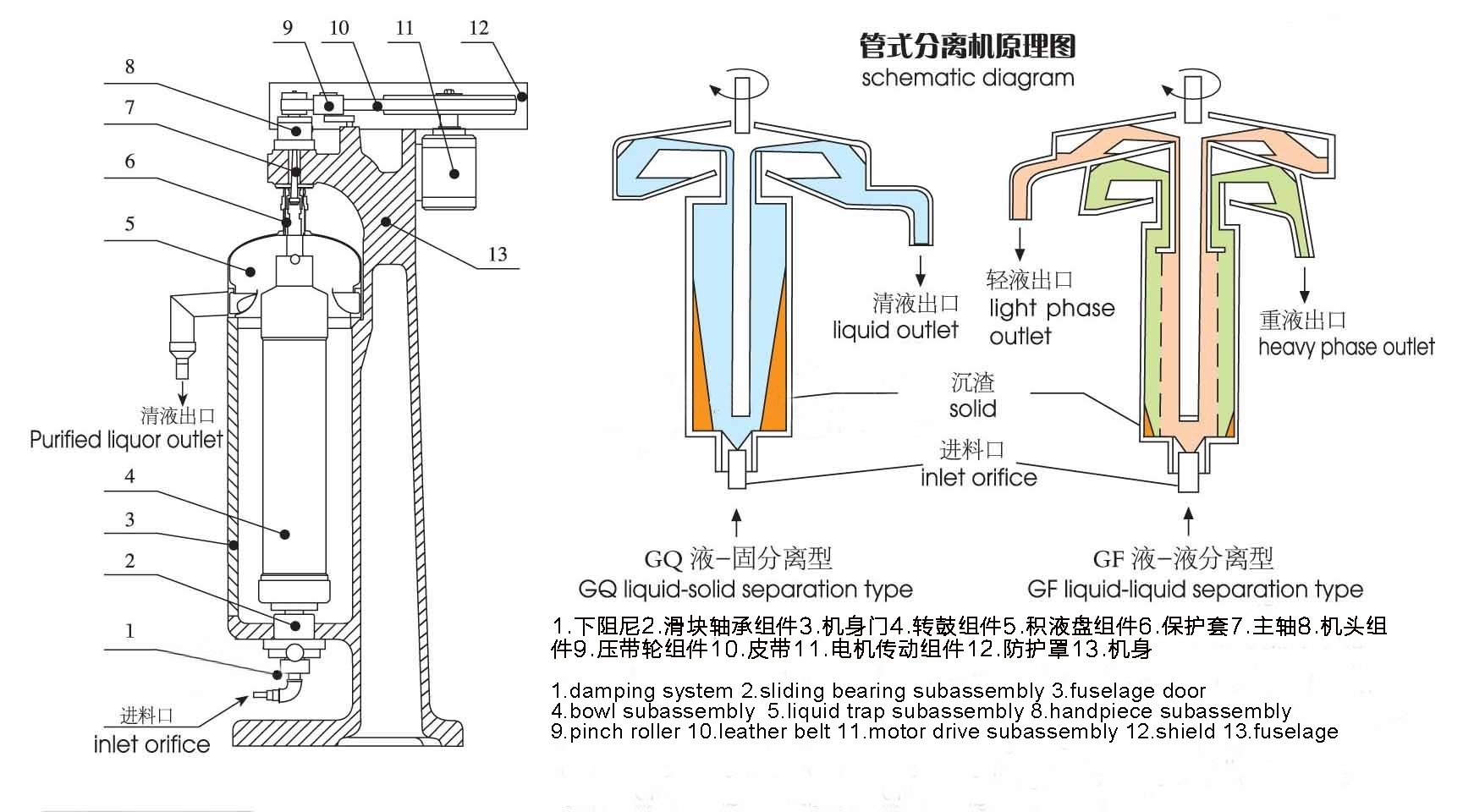

General tubular centrifuge separator has 2 model series.

GQ series - two phase that can separate solid from the liquid.

GF series, which can separate the water, solid from the oil.

The Application of tubular centrifuge separator

It has been widely used in pharmaceutical, health food, drinks, chemical industries to separate the liquid-solid or

liquid-liquid-solid materials. It is an ideal centrifuge take advantage of centrifugal methods, the minimum granules is 1 um,which is suitable for distill, condense and clarify the material has small gravity difference, small and few solid granules and high erosion products.

GF model is suitable for separating various emulsion, especially for two states specific gravity difference liquid-liquid and

contain small impurities liquid-liquid-solid separation, for example: transformer oil, tubine oil, lubricating oil, fuel oil,

dyes, oil resins, saponification, various powder materials, purification span-80 material liquid, various oral, various

pharmaceutical liquid, "920" separation; blood plasma biological pharmaceutical separation and animal blood plasma extracted; edible oil, cai plate soaking liquid, polyphenols, soy lecithin refining, oil water separation and seqage treatment.

Working principles

The machine is composed of main body, transmission device, drum, liquid collecting tray, and liquid-feeding bearing base. There is a flexible main axis on the top of drum, and a damping floating bearing at its bottom. With the linked buffering device, the main axis is connected with the passive wheel. Through the conveyor and the fastening wheel, motor provides power for the passive wheel, so the drum rotates around itself axis by high speed, and form strong centrifuge force field. Materials are launched from the bottom feeding inlet, by the centrifugal force, liquid flows upward along the drum wall, and is separated to layers because their different density.

Centrifugal sedimentation, a well‐known solid‐liquid separation process, is typically used for the separation of solids from low concentration feeds because of its high separation efficiency due to high settling velocities. The performance of the tubular bowl centrifuge GQ) can be studied by using the sigma theory, which assumes plug flow and rigid body motion inside the rotating bowl wall. The separation efficiency of the system is evaluated by determining the effective fluid layer thickness from the experimental data. A method suitable for evaluating the separation efficiency at different parameters for a given GQ is explained along with experimental validation. By using this method, different case studies are performed which depict the influence of each parameter on the separation efficiency. Also, it is demonstrated that the same higher separation efficiency (98%) at 20000rpm could be achieved at higher bowl capacities.

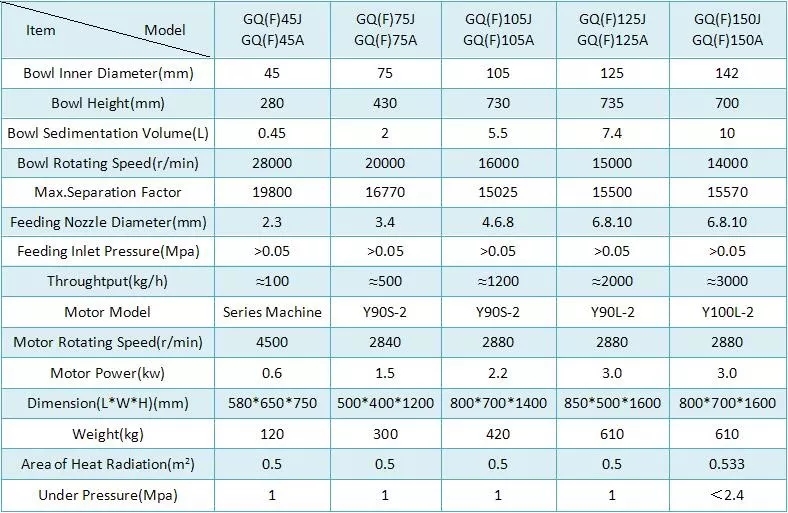

Technical Paramter of the tubular centrifuge :

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1