In response to the characteristics of xanthan gum, Shenzhou has specially developed a horizontal screw centrifuge for xanthan gum separation.

In response to the characteristics of xanthan gum, Shenzhou has specially developed a horizontal screw centrifuge for xanthan gum separation.

Separation is an important step in the production of xanthan gum.

The horizontal screw centrifuge developed by Shenzhou meets the production requirements of xanthan gum and has received unanimous praise from customers for its separation effect.

Pretreatment of raw materials:

After refining primary starch into starch milk, it enters the continuous sterilization gelatinization system to prepare a clear and impurity free starch gelatinization liquid. The nitrogen source is hydrolyzed using soybean cake powder under specific conditions, and then centrifuged to remove the residue to obtain a turbid liquid without visible suspended particles.

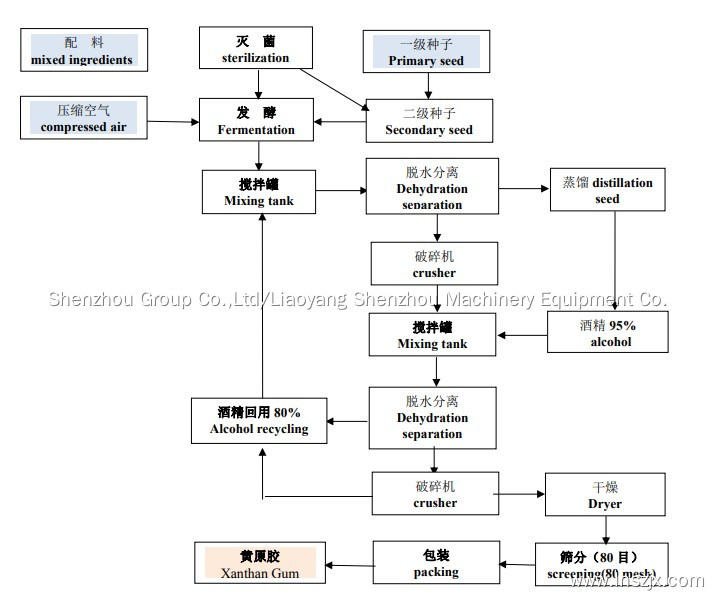

Sterilization: The processed carbon and nitrogen source culture medium is instantaneously heated to 120 ℃ using an automatic continuous sterilization method, maintained for 10 minutes, and then the heat energy of the material is recovered, cooled to the desired temperature.

Strain expansion culture: primary and secondary seed tanks culture for 13 to 18 hours, with a culture temperature of 28 to 30 ℃. They have a large number of cells, a robust body, and evenly stained mature seeds.

Fermentation: After the fermentation tank is empty and cooled to about 30 ℃, the secondary seeds are inoculated into the fermentation tank using differential pressure. The temperature of the fermentation tank is maintained at 28 ℃, and the fermentation time is 60-70 hours with ventilation and stirring.

Extraction and drying: Use alcohol to extract xanthan gum from fermentation broth, wash the mash and alcohol twice in a tank, remove the solvent, press, and enter a vacuum drying device. During the drying process, recover alcohol, and dry to a moisture content of 10-12%.

Packaging: The material is crushed by a pulverizer and made into 80 mesh petroleum grade xanthan gum as required.

Ethanol recovery: Waste ethanol used for elution is distilled in distillation column and then re-entered the system for use

Xanthan gum product quality: Implement petroleum grade quality standard

Xanthan gum product quality: Implement petroleum grade quality standard

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1