Application of beer centrifugeCentrifuge applications in craft beer include pre-filtration, yeast count control, and recovery of wort from hot clots. Centrifugation is an important step in the brewing process, in which a beer centrifuge removes solids such as yeast and hops from draft beer and transfers them to a mature container for final conditioning, preventing unwanted particles from entering the final productCharacteristics of beer centrifugeMany brewing equipment manufacturers have been able to design and manufacture high-quality, fully functional new beer centrifuges. Let's take a look at the features of this centrifuge: It has an inert gas containment system that minimizes oxygen entry into the clarifying product, ensuring that the oxygen gain behind the centrifuge does not exceed 10ppb. Ability to monitor all functions and self-adjust to maintain operational Settings, ensuring always trouble-free and safe operation. Centrifuge self-cleaning design, no disassembly cleaning, with CIP online cleaning system. Through the circulatory system, the beer stays cool enough.Advantages of beer centrifugeCompared with traditional filtration and precipitation methods, centrifuges can significantly reduce processing time and increase production. Control clarification of total suspended solids in beer prior to direct bottling. Keep inlet and outlet temperatures low to minimize flavor and texture loss, thereby extending product shelf life. With variable frequency drive, improved service life and reduced cost, craft beer can earn a return on investment in a short time.

Features:1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise and vibration, the installation path is very easy to operate. 2.The Stainless steel cover use SUS304. 3.The base use casting steel, coating does the same way as ship bottom. 4.Independent electric control cabinet can be remote controlled. 5.Safety protection: Rotating speed detection, over-vibrating protection, cover opening protection, motor

|  |

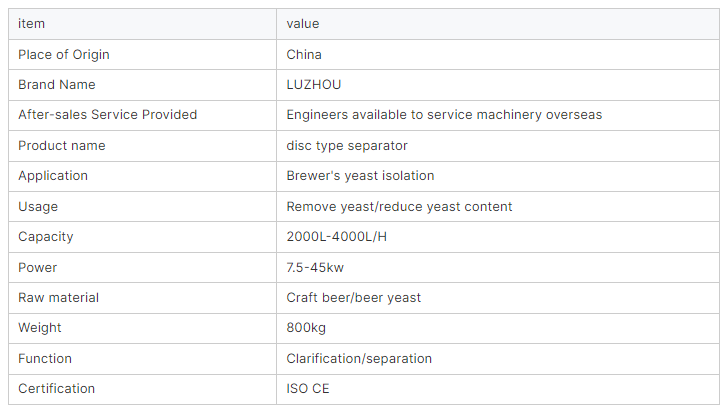

Application of beer centrifuge

Centrifuge applications in craft beer include pre-filtration, yeast count control, and recovery of wort from hot clots. Centrifugation is an important step in the brewing process, in which a beer centrifuge removes solids such as yeast and hops from draft beer and transfers them to a mature container for final conditioning, preventing unwanted particles from entering the final productCharacteristics of beer centrifugeMany brewing equipment manufacturers have been able to design and manufacture high-quality, fully functional new beer centrifuges. Let's take a look at the features of this centrifuge: It has an inert gas containment system that minimizes oxygen entry into the clarifying product, ensuring that the oxygen gain behind the centrifuge does not exceed 10ppb. Ability to monitor all functions and self-adjust to maintain operational Settings, ensuring always trouble-free and safe operation. Centrifuge self-cleaning design, no disassembly cleaning, with CIP online cleaning system. Through the circulatory system, the beer stays cool enough.Advantages of beer centrifugeCompared with traditional filtration and precipitation methods, centrifuges can significantly reduce processing time and increase production. Control clarification of total suspended solids in beer prior to direct bottling. Keep inlet and outlet temperatures low to minimize flavor and texture loss, thereby extending product shelf life. With variable frequency drive, improved service life and reduced cost, craft beer can earn a return on investment in a short time.

Features:1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise and vibration, the installation path is very easy to operate. 2.The Stainless steel cover use SUS304. 3.The base use casting steel, coating does the same way as ship bottom. 4.Independent electric control cabinet can be remote controlled. 5.Safety protection: Rotating speed detection, over-vibrating protection, cover opening protection, motor

The beer separator was exported to Azerbaijan, and the engineer went to Azerbaijan for debugging on March 26, 2024. The customer is very satisfied with the separation effect.

If you have difficulty separating beer, you can always contact us. We will provide you with a satisfactory answer with our professional knowledge!

|  |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1