Ethanol Centrifuge Extractor For Hemp CBD Oil

After years of development, we have introduced and upgraded the technologies so as to make the manufacturing process more efficient.As more and more Hot sale Low Temperature Herbal CBD Oil Industrial Basket Extraction Hemp Centrifuge Machine advantages have been gradually discovered, the product enjoys a wider range of application uses and now can be found in the field(s) of Extractor.

thanol Centrifuge Extractor For Hemp CBD Oil

The LCE Series extraction centrifuges focus on extracting the hemp and other plant species you need. High-purity extraction of specific plants is efficiently performed by a programmable touch control program.

6 Advantages Of CBD Centrifugal Extractor

1. LCD touch screen, PLC controller system. Frequency control cabinet. Explosion proof motor.

2. Large visible window, can observe working condistion easily and clearly.

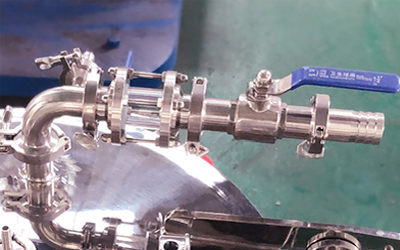

3. Ethanol feeding port with valve.

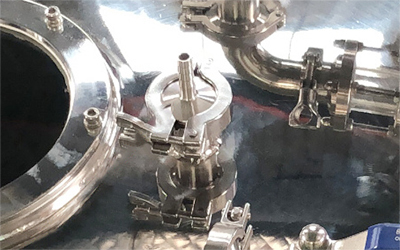

4. Vacuum port with quick clamp, can match vacuum pump for negative pressure feeding.

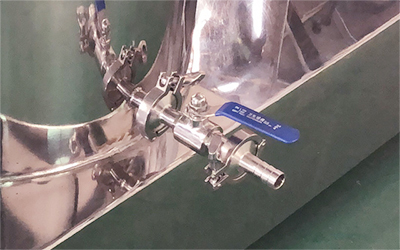

5. Discharge port with controller valve.

DESCRIPTION

The LCE Series Centrifuge is an all-in-one system that combines closed low temperature alcohol extraction with mechanical centrifugation. With PLC controller and LCD touch screen, with forward/reverse/dehydration functions and the ability to set the time and number of cycles, all of which can be programmed according to actual usage for more efficient separation. The system's one-cycle run time is approximately 10-15 minutes, ensuring high quality raw extracts in a short period of time.

FEATURES

1. 98% plant extraction rate

2. 97% alcohol removal rate

3. The part in contact with the materials made of SUS304 or SUS316L, and the surface is treated with sanitary grade and no dead angle, easy to clean.

4. The inlet port and outlet port adopt a hygienic quick clamp with a valve.

5. All seals are sealed with PTFE or fluorine rubber, and the main shaft is double-layer fluorine seal water seal/oil seal.

6. Explosion proof motor with 220V 3phase (220V single-phase is optional), PLC and touch screen control, frequency conversion control cabinet.

7. Equipped with two inlet/intake tubes, one vacuum port with valve, one drain port, inlet and outlet port for recirculating chiller.

8. The cylinder is jacketed type, can connect with recirculating chiller for cooling.

9. The base is equipped with four lifting rings for easy loading and unloading.

10. Equipped with 10m cable and control cable, can use it directly after electrical connection.

Extraction cycle:

The LCE series centrifuge extractor offers 3 program cycles: spray wash, stirred wash and spin dry cycle. Each program cycle can be run automatically or manually. The operator loads the ground plant material into a filter bag and places it in a centrifuge, rotating it at different speeds in the system while injecting alcohol at a controlled rate. The centrifuge can also be submerged and stirred in both directions to completely extract the cost of the plant. After washing, the plant material is subjected to high-speed spin-drying to remove 97% of the residue on the plant material, and the active ingredient extraction rate is as high as 98%. The alcohol wash can be recycled 2-3 times or directly for further processing.

1) System loading

Place the filter bag filled with plants into the drum and seal the system.

2) Cleaning cycle

Select the speed and time of forward and reverse rotation in the program menu to perform the spray washing operation.

3) Alcohol filling

A pneumatic pump is used to pass the low temperature ethanol through the inlet pipe into the system.

4) Extraction begins

The plant material in the centrifuge is stirred and washed, and a certain number of two-stage agitation cycles are set, so that 98% of the plant active ingredient can be extracted.

5) System drainage

After the cleaning cycle is complete, open the outlet valve venting system. The alcohol wash is pneumatically pumped to a suitable reservoir for further processing.

6) High speed dehydration

Select the “Dehydration” program on the program menu to start the high speed dehydration cycle. Thoroughly dry the alcohol solution on the wet plant surface.

| Model | HHP-15 | HHP-25 | HHP-45 | HHP-65 | HHP-115 | HHP-145 | HHP-250 |

| Capacity (L) | 15 | 25 | 45 | 65 | 115 | 145 | 250 |

Drum diameter (mm) | 300 | 300 | 450 | 450 | 600 | 600 | 800 |

Drum height (mm) | 250 | 350 | 300 | 400 | 400 | 500 | 500 |

| Rotational speed(RPM) | 2000 | 2000 | 1500 | 1500 | 1250 | 1250 | 1100 |

Motor power (Kw) | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 11 |

Dimension (mm) | 1100*650*1020 | 1100*650*1020 | 1400*850*1080 | 1400*850*1080 | 1600*1060*1250 | 1600*1060*1330 | 1700*1400*1600 |

| Weight(kg) | 240 | 260 | 450 | 470 | 1000 | 1030 | 1350 |

| Motor | Explosion proof motor | ||||||

| Control | PLC controller, LCD touch screen | ||||||

| Material | Stainless steel material | ||||||

WHY CHOOSE US Factory direct sales with competitive price. Premium quality with CE & ISO certification. Strong product OEM & ODM customization capability. Promise production & on-time delivery. Perfect after-sales service, free product accessories. 15 years of experience in R&D and production of centrifugal extractor machine. | |||||||