Shenzhou - PLD series Bottom Discharge Centrifuge Centrifuge & Separator

Technologies are essential to the manufacturing of PLD series Bottom Discharge Centrifuge.After being upgraded for several generations, the newest product has been proved to have more extensive uses in Separation Equipment and other fields.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd conforms to the development trend of the industry, integrates internal superior resources, adopts the industry's cutting-edge manufacturing technology and production technology, and successfully creates PLD series Bottom Discharge Centrifuge with excellent performance and reliable quality. By accurately grasping the pain points of customers, the PLD series Bottom Discharge Centrifuge developed by us has been supported and praised by the majority of customers in the market. In the future, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd will rely on strong R&D capabilities to update and iterate the original products, and strive to provide customers with better quality products. Not only that, the company will also uphold the service concept to Improve services and strive to provide services that exceed customer expectations.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | hot product | Warranty of core components: | 1 Year |

| Core Components: | Motor | Brand Name: | Shenzhou |

| Voltage: | 380V | Power: | MODEL |

| Weight: | 3500 | Dimension(L*W*H): | MODEL |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Hotels, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | United States |

| Certification: | GMP/CE |

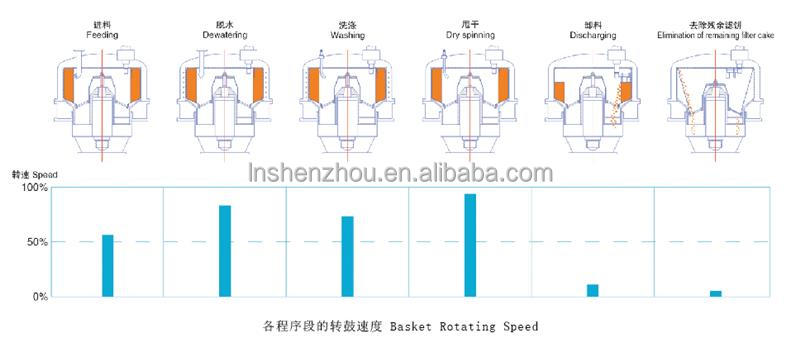

Material to be separated enters into the basket of the centrifuge that is rotating at high speed through a feeding pipe, and under action of the centrifugal field, the material passes through the filter cloth (screen) for filtration. Then the liquid phase

discharges through the discharge pipeline, while the solid phase is retained in the basket. Feeding stops once the basket is filled with the material, then wash the solid cake, and discharge the washing liquid through filtration. The centrifuge continues to rotate to spin-dry the solid cake. After the solid cake meets the requirements for separation, the centrifuge reduces its speed, and removes the cake by means of the scraper, then discharges the cake out of the centrifuge. The centrifuge further reduces its speed so that the pneumatic pulling bag device moves reciprocally to shake off the residual solid cake, thus completely eliminating the solid cake.

Main features of LDP centrifuge:

In addition to all main features of the LGZ series centrifuge, LDP series centrifuge features as follows:

◇Removing the residual solid cake by bag-pulling method. Eliminate all solid cakes left over the process of scraper discharging through reciprocal movement of the pneumatic pulling bag device, to realize complete discharging and filtering cloth regeneration.

◇Design of removable lip ring in the basket with reliable self-locking, which is easy for changing the filter cloth.

◇External cylinder+rod drive design, reliable in work

◇Fully-enclosed discharge hopper design separating the material from the driving components of the centrifuge.

◇ External construction: Multiple constructions including big hinged cover, fully hinged cover and flat cover

◇ Feed type: Inclined feed disk, side feed pipe, middle feed pipe and material level detection device

◇ Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

◇ Motor drive: Common motor, inverter-duty motor and explosion-proof motor

◇ Safety protection: Nitrogen protection (anti-explosion) system, vibration protection, temperature protection,

electric-mechanical interlocking, speed monitoring and overload protection.

◇ CIP system: Cleaning ball and spray pipe

◇ Washing mode: Atomized nozzle rinsing, feed disk washing, pulse type washing

◇ Nitrogen protection system: Automatic control device, hydraulic sealing device and gas-liquid separator.

Rapid replacement of LDP pulling bag:

Step1: open the lid (hydraulic operation)

Step2: Take down the snap ring of basket lip of filter bag and take out the steady pin of liquid interception plate and life out

the liquid interception plate.

Step3: Take down the snap ring under filter bag and take out the old filter bag.

Step4: install the new filter bag and tension the snap ring under filter bag.

Step5: install the liquid interception plate and steady pin of liquid interception plate and tension the snap ring of liquid

interception port of filter bag.

Step6: close the flip and lock it.

Step7: inspect the fitting condition of filter bag and confirm it by pulling bad.

Model | LDP800 | LDP1000 | LDP1250 | LDP1600 | LDP1800 |

Basket Dia (mm) | 800 | 1000 | 1250 | 1600 | 1800 |

Basket Volume (L) | 100 | 175 | 400 | 800 | 1250 |

Max. charge (kg) | 135 | 235 | 500 | 1000 | 1500 |

Rotation Rate of Basket (r/min) | 1200/1500 | 1100/1200 | 1000/1200 | 850 | 800 |

Relative Centrifuge Force | 645/1008 | 677/805 | 700/1008 | 647 | 645 |

Power of Motor (kg) | 7.5/11 | 15 | 22/30 | 37 | 55 |

Overall Dimension (mm) | 2050*1250*2000 | 2350*1450*2350 | 2550*1800*2550 | 3200*2400*3000 | 3500*2500*3300 |

Weight (kg) | 2000 | 3500 | 5000 | 10000 | 15000 |

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian