Our professional employees are skilled at utilizing technical resources. By utilizing technology, we ensure the product manufacturing process goes efficiently.In the application field(s) of Separation Equipment, DHC500 Disc stack Centrifuge separator can play out its greatest effect.

Product Description

Disc stack centrifuge is a kind of vertical centrifuge. As a high-efficiency, high-output, high-automation and high-speed precision separation equipment, it can be divided into solid-liquid two-phase and solid-liquid-liquid three-phase separation. As a two-phase separation disc centrifuge, it can separate most solid particles and liquids. As a three-phase disc centrifuge, it can separate liquid phases of different densities and separate solids at the same time.

The disc centrifuge is equipped with a PLC controller and CIP automatic cleaning system. If there is a risk of explosion in the material handling process, an inert gas device can be used to prevent the leakage of combustible gas and ensure safety, which meets the requirements of explosion-proof standards.

Disc stack centrifuge features:

The separation factor of disc centrifuge is generally 8000 ~ 20000G. It is usually used to process materials that are difficult to effectively separate by conventional centrifuges, such as highly dispersed liquid-liquid two-phase emulsions, slow-settling liquid-solid two-phase suspension with small solid particles, etc. It can separate suspensions with a solid concentration of less than 3%. The technical parameter range of disc centrifuge is relatively large, and the diameter of the drum is generally 150 ~ 1200 mm. The disc centrifugal separator can provide a better result of separation with a clearer centrate, and can be adopted in more areas with its wide range of technical parameters.

Working Principle Of Vertical Disc Centrifuge

Disc centrifuge is a kind of industrial centrifuge used to clarify and separate liquids. It also belongs to vertical centrifuge. Because there is a set of disc-shaped parts (discs) nested together in the drum named disc centrifuge. The drum is driven by a motor through a vertical shaft to rotate at a high speed. The material enters the disc centrifuge drum through the feed pipe, and then enters the disc group. It accelerates in the distribution chamber until synchronized with the speed of the drum. When the suspension (or emulsion) flows through the gap between the discs, the solid particles settle on the discs to form sediment under the action of centrifugal force. The sediment slides along the surface of the disc, then it separates from the disc and accumulates in the part of the drum with the largest diameter - solid slag collection chamber. The solid phase is discharged by controlling the sealing water and slag water, and the separated liquid is discharged from the liquid outlet. The function of the disc is to shorten the settlement distance of solid particles and expand the settlement area of the drum. The installation of the disc in the drum greatly increases the production capacity of the separator.

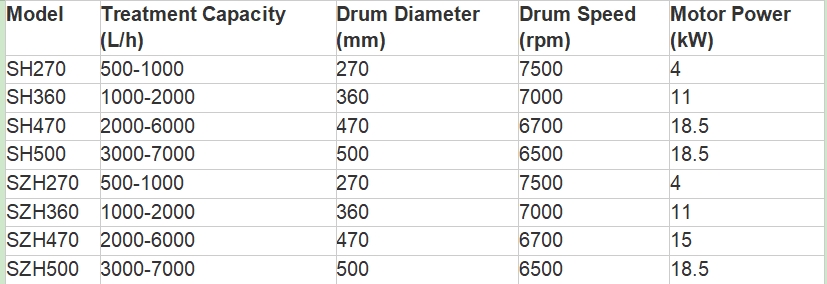

Technical Parameter

Our Customers

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1