LW decanter Centrifuge have large rotating drum and large capacity.This centrifuge L/D ratio is 3.5:1 or 4:1. It's a full frequency centrifuge. All electronic control components are from international famouse brand: ABB/Siemens.

The electronic load sensing and the intelligent control of the feed pump ensure that the feed volume, rotation speed and differential speed of the centrifuge can automatically reach the rated state in the automatic working state. Rotation speed, motor load and bearing temperature state (optional) are directly displayed on the touch screen operating panel, intuitive, to ensure that the centrifuge can reach the rated working state throughout the whole process.

Product Description

LW series decanter centrifuges usually used dewatering and thickening purpose. It is widely used for maximum dewatering requirements of municipal and industrial wastewater sludge.

Large size, medium speed of 2400-2600r/min, large processing capacity and high density difference of solid and liquid, low viscosity, high concentration, high treatment capacity and higher dryness than clarity, users can flexibly select according to their own characteristics. According to the actual use, it can be divided into: clarification type, dehydration type, concentration type, separation type, classification type and extraction type.

ln the actual project, it has been used in the following industries: mono sodium glutamate, oilfield drilling mud, thermo-electric desulfurization, magnetic particle treatment, sewage treatment, pharmacy, food, laboratory, petroleum, new energy, biotechnology, chemical fiber, polymeric materials, leather manufacturing, cosmetics, printing and dyeing, knitting, etc.

Introduce

Shenzhou LW decanter centrifuge is a large rotating drum large capacity centrifuge.This centrifuge L/D ratio is 3.5:1 or 4:1. It's a full frequency centrifuge. All electronic control components are from international famouse brand: ABB/Siemens.

The electronic load sensing and the intelligent control of the feed pump ensure that the feed volume, rotation speed and differential speed of the centrifuge can automatically reach the rated state in the automatic working state. Rotation speed, motor load and bearing temperature state (optional) are directly displayed on the touch screen operating panel, intuitive, to ensure that the centrifuge can reach the rated working state throughout the whole process.

Main Characteristics

1. Continuous working, spiral discharging, high capacity.

2. Compact structure and easy maintenance.

3. Wide applicability for chemical, oil, foodstuff, pharmacy industries and green industry in which solid-liquid separation is required.

4. Suitable for various products, capable for separating wide-ranging solid phase grains( 0.005 - 2mm ), especially when separating solid phase has different size grains.

Main Choices

According to user’s requirement, the product contact parts can be made of austenite stainless (321, 316L….), Haynes alloy, titanic alloy or other anti-erosion materials.

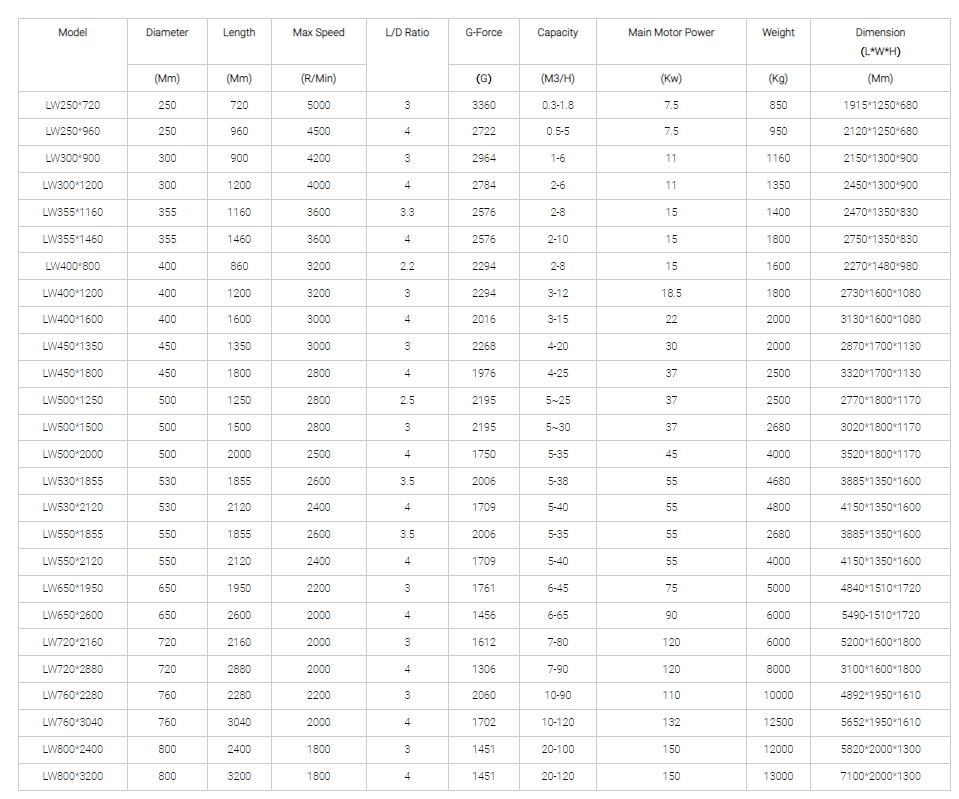

Technical Parameter

Application

● Mud purification treatment of shield piling project

● Channel dredging

● Industrial wastewater treatment

● Solid control of drilling fluid

● Marine oil pollution recovery

● Oil residue separation

● Municipal sewage purification project

● Mining wastewater treatment

Products Packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient shipping packaging services will be provided.

Technical Service

- Technical direction when installation, debugging

- Training for operation and maintain worker

Training

- Separator working principle and structure

- operation regulation and attention

- machine maintains

Customers from other countries visited Shenzhou

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1