Shenzhou decanter centrifuge has huge technical advantages in the recovery process of coal tar solid-liquid separation and dewatering. Because we have more than 40 years of experience and technology precipitation in industrial centrifuges. Shenzhou is the leading decanter manufacturers in China. No other manufacturer of decanter centrifuges has so much experience in tar cleaning as we do.

Shenzhou coal tar decanter centrifuges feature a horizontal bowl with a scroll conveyor inside that rotates at high speeds to generate centrifugal forces. The centrifugal force separates the solid particles from the liquid, which are then discharged through separate outlets. This process is highly effective in achieving coal tar separation, resulting in improved product quality and reduced waste.

Shenzhou--Decanter Centrifuge For Coal Tar Recovery Process

Shenzhou decanter centrifuge has huge technical advantages in the recovery process of coal tar solid-liquid separation and dewatering. Because we have more than 40 years of experience and technology precipitation in industrial centrifuges. Shenzhou is the leading decanter manufacturers in China. No other manufacturer of decanter centrifuges has so much experience in tar cleaning as we do.

Shenzhou centrifuge has the characteristics of compact structure, easy sealing, stable operation, low noise, large processing capacity, low energy consumption, high degree of automation, low labor intensity, convenient operation and maintenance.

How The Coal Tar Decanter Centrifuge Work

The coal tar mixture is fed into the centrifuge, which spins at a high speed to create a strong centrifugal force. This force separates the heavier solids from the lighter liquid, allowing them to be discharged separately.

The decanter centrifuge is particularly useful in coal tar applications because it can handle high volumes of material and can separate solids with a high level of efficiency. This helps to reduce the amount of waste generated during the process and can also improve the quality of the final product.

In addition, the decanter centrifuge can also be used to recover valuable materials from the coal tar, such as coal dust or fines. These materials can be separated from the liquid phase using the centrifuge, allowing them to be reused or sold for other applications.

Product Advantage

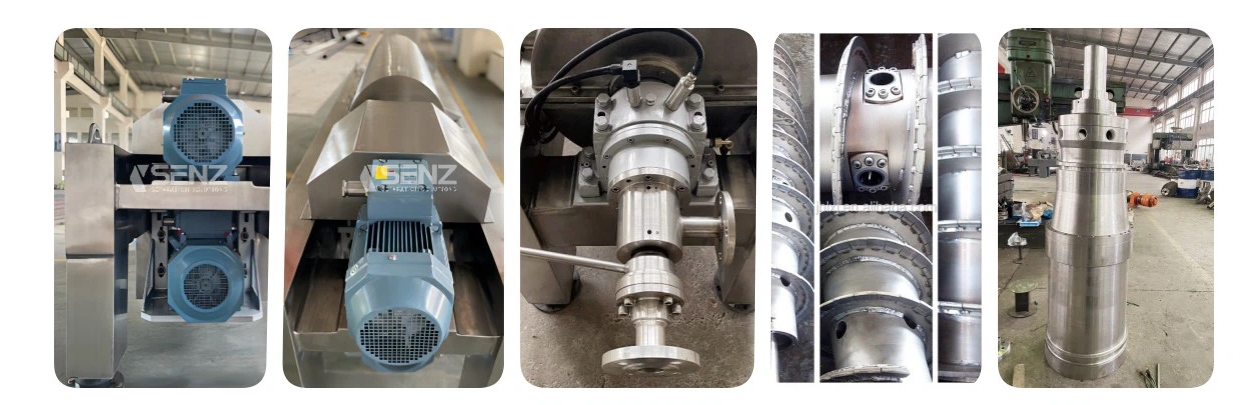

These centrifuges are made from high-quality materials, including stainless steel, and are designed to withstand harsh operating environments. They also feature advanced control systems, including variable frequency drives, automatic lubrication systems, and overload protection devices, ensuring smooth and reliable operation.

Shenzhou coal tar decanter centrifuges are highly efficient, handling large volumes of coal tar quickly and effectively. They also offer a range of marketing advantages, demonstrating a commitment to quality and innovation that customers are sure to appreciate. Additionally, their efficiency and effectiveness can help businesses reduce waste volume and increase production efficiency, delivering significant cost savings over time.

Product Description

Raw tar from coking contains not only water with dissolved ammonia, hydrogen sulphide and aluminium chloride but also coal dust. Cleaning and processing of tar largely separates out the water and solids. The purity of tar has a decisive effect on its market value.

During processing of tar, decanters separate the solid impurities out of the raw tar. The cleaned tar contains less than 0.3% quinolin and insoluble solid particles larger than 50 μm. The separated solid has a total dry solids of approx. 33 - 40% and its consistency is between clumpy and almost solid.

During tar cleaning, Shenzhou decanter centrifuge simultaneously separate out the ammonia water and solid particles. The cleaned tar has a water content of less than two perce

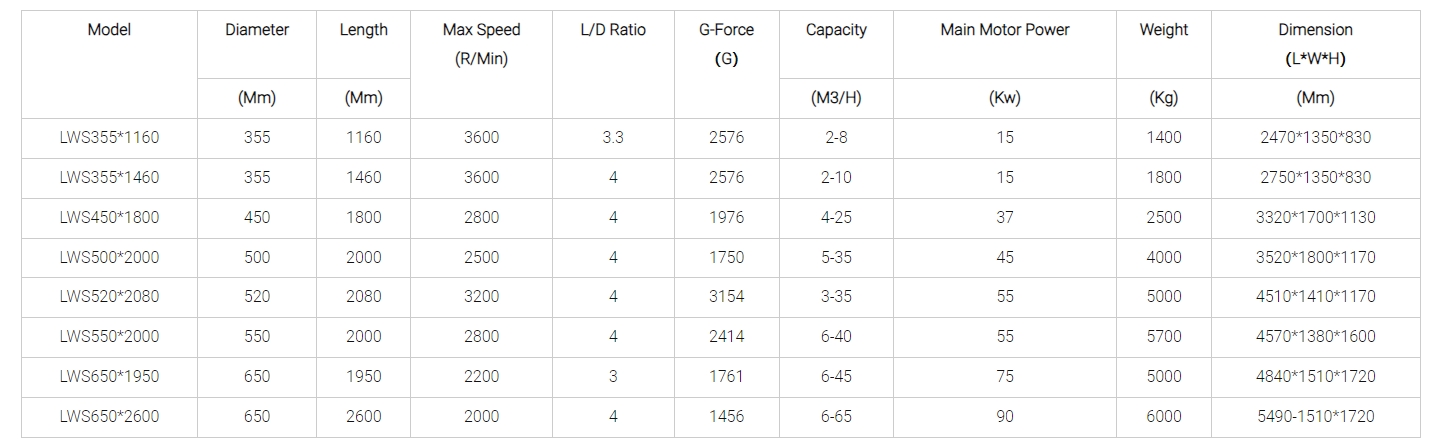

Technical Parameter

Coal Tar Decanter Features And Benefits

● Increasing The Value Of Tar By High Purity

● Reduces Operating Costs

Lower costs for maintenance and servicing due to lower wear on system components such as pumps, valves, etc.

Less contamination of the tar storage facilities leads to lower costs for cleaning

Increasing the value of tar by high purity

● 40 Years Of Technical Experience

● Mobile Separation Systems And Skids

The mobile systems give you increased flexibility and enable you to respond quickly to changing deployments.

● High-Quality Wear Protection

Our decanters are protected against wear by carbide plating, tungsten carbide and silicon carbide ceramics. The service life of the wear protection in our centrifuges for tar cleaning is generally in excess of 15,000 operating hours.

● Shenzhou Drive

The Shen zhou Drive regulates the differential speed according to the scroll torque. The centrifuge automatically adjusts to different load statuses and concentrates the separated solid to achieve the maximum total dry solids.

● Complete Systems

We supply complete centrifuge plants specifically for use in coking plants. These consists of a Shenzhou decanter and Tricanter machine as well as the control unit, explosion-proof switchboard, automatic inflow regulation, mass flow measurement,PLC control, spare parts unit.

Configuration

Customer Photos

Packing & Delivery

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1