Continuous High Flow - Algae Separator Centrifuge compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Shenzhou summarizes the defects of past products, and continuously improves them. The specifications of Continuous High Flow - Algae Separator Centrifuge can be customized according to your needs.

Product Description

Algae harvesting with the SHENZHOU Separator

The algae suspension flows from the photobioreactor directly into the Separator. Then the distributor gently accelerates the suspension to full speed. Due to the high centrifugal force of up to 12,000 g, the separator dewaters the algae suspension producing an algae concentrate with creamy consistency. Thus making the algae concentrate ideal for further processing. Small to medium-sized plant benefit in particular from the low investment and low operating costs of the single-stage process.

1.up to 25 percent lower investment costs

2.lower costs for further processing or drying due to a very high-quality algae concentrate

3.suitable for medium and small businesses

Working Principle

SHENZHOU separator is mainly used to remove water and algae such as Spirulina,green algae etc in the lake and sea. which is very fine even can not be visible by eye. With high G-force during the running, the separator could get the concentration liquid with algae about 10%.

The machine adopts automatic control, it has the advantages of high efficiency, low oil consumption, convenient operation and economic maintenance cost.The sludge is discharged automatically and fully.

The machine is one kind of rotary machine with high speed, After accurate dynamic balancing, it can run for long time with low vibration, safety and security.

6.The design, product and acceptance are conformed to the standard of GB/T5745 “Disc Separator”.

Advantage of Shenzhou alage separator

1.continuously discharge

2.variable discharging means(adopting double small valve variable discharging structure, the partial discharging mode combined with full discharging mode,achieving the variable discharging by changing through electric control parameters to increase separator's discharging reliability.

3.geared drive, bowl,piston and hood are made of high-strength corrosion-resistant stainless steel Cr-Ni-Mo

4.other material contact parts(like discs,cover and machine body) are made of high-quality stainless steel SUS304

5.both vertical shaft and horizontal shaft are made of 20Cr13, all bearings are adopt SKF brand.

6.The equipment has vision glass and sampling export. Machine cover and machine body adopt mezzanine cooling, it can decrease the temperature of shell, also decrease the vibration and noise of the whole machine.

7.The equipment adopt variable frequency starting, it no need to change the friction plate and lubricating oil.

8.The equipment adopt vibration alarm device, in case the vibration strongly exceeds a set value, alarm start, if long time nobody handle, the machine will stop automatically.

9.In case over current or over load, the machine will stop automatically, ensure that the machine safely operation.

10.The equipment is automatic and manual dual operation.

11.The equipment with internal removable form, it can achieve the purpose of clean the inner part which is sealed, ensure the equipment and annex no cleaning dead corner.

12.The equipment's inner part with polishing,outer parts with dull processing, the screws,screw nuts and flat pad are made of SUS304, all interfaces are 1.6MPa flange interfaces or quick chuck.

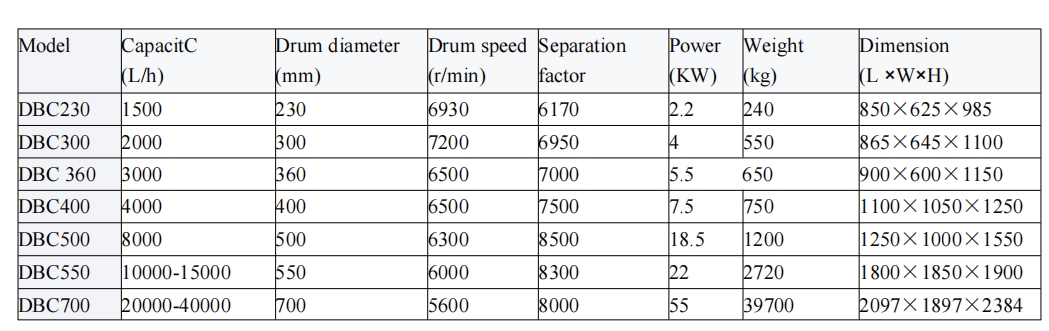

Technical Parameter

customers Visited Shenzhou from other counties:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1