Professional Three phase decanter manufacturers

3 Phase Centrifuge

Product Name:LWS355 Three Phase Centrifuge

LWS355 decanter centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials. With our over 40 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation. It's new, advanced, mature, complete,safe and reliable, and the technical performance meets the requirements in the technical annex. The design, manufacture and quality of the LWS355 centrifuge are better than the standard of JB/T502-2004 spiral discharge sedimentation centrifuge, and the product has passed ISO9001-2000 quality system certification.

Product Description

LWS355 three-phase centrifuge is mainly designed for Solid-liquid-liquid three-phase separation of materials. This machine is a counter current 3-phase horizontal spiral discharge settling centrifuge, consisting of a column cone drum, a spiral discharge device, a differential system, a bearing seat, a base, acover, a main and auxiliary motor, and an electrical system. With our over 40 years of experience in the separation industry, it is the most advanced type machine for 3 phase separation.

The LWS355 decanter centrifuge provided by Jinhua Shenzhou. It's new, advanced, mature, complete,safe and reliable, and the technical performance meets the requirements in the technical annex. The design, manufacture and quality of the LWS355 centrifuge are better than the standard of JB/T502-2004 spiral discharge sedimentation centrifuge, and the product has passed ISO9001-2000 quality system certification.

For some materials that are difficult to separate, in addition to taking corresponding adjustment measures for the separat-ed materials themselves, the centrifuge can also be adjusted and improved accordingly:

1. Increase the length diameter ratio

2. Adjust the rotating speed of the drum

3. Adjust the differential speed between the drum and the discharge screw

4. Change the half cone angle of the drum cone section and adopt multi cone angle sorew

5. Adjust the overflow radius of the liquid phase outlet

6. Change the number of screw heads and screw lifting angle of discharge screw

7. Add BD plate structure

Combined Driving Mode

Single Motor Drive: Single motor drive generally adopts a frequency conversion motor + frequency converter to drive the drum and screw at the same time.

The method is simple, the operation is simple, and the manufacturing cost is low. Single motor drive is mainly used for materials with constant solid content, and there is no strict requirement for the water content of the discharged solid phase. Because there is no necessary differential adjustment mechanism, the differential between the drum and the screw can only be realized by changing the gear transmission ratio or changing the drum speed.

Dual Motor Drive: Dual motor drive generally adopts two frequency conversion motors + two frequency converters tocontrol the dynamic rotation of drum and screw respectively.

ln the dual motor drive mode, the differential speed between the drum and the screw is adjusted by simply adjusting the speed of the motor. This driving mode is applied to materials with variable solid content and strict requirements for discharged solid water content.

Hydraulic Drive: The hydraulic drive generally adopts frequency conversion motor + frequency converter + hydraulic motor to drive the drum and screw respectively.

ln the hydraulic drive mode, the differential speed between the drum and the screw can be adjusted by the hydraulic motor. When moving at very low differential speed, its degree and stability are better than other driving methods.When the drum rotates normally, both the drum and the screw operate at a certain constant speed. Once the load of the screw pusher increases, the hydraulic motor will adjust the screw pusher to accelerate the operation to prevent material blockage.When the machine is stopped for cleaning due to material blockage, the hydraulic system can drive the screw pusher independently to improve the cleaning and maintenance efficiency.

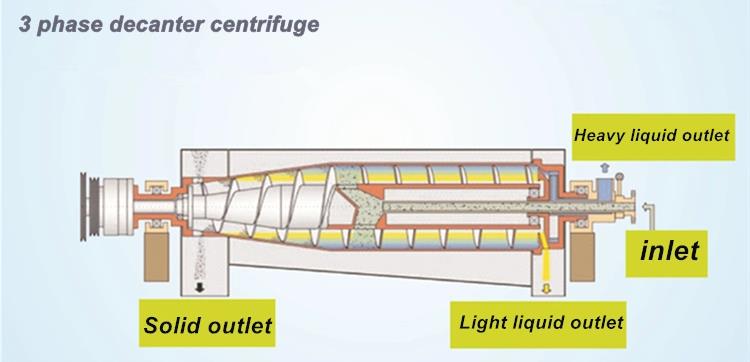

Structure And Working Principle

In the three-phase horizontal screw centrifuge, the materials to be separated enter the acceleration chamber of the screw pusher through the feed pipe and then enter the inner wall of the rotating drum at high speed. Due to the different specific gravity of light liquid phase heavy liquid phase insoluble solid phase in the materials, the centrifugal force on the three-phase materials is different, and the insoluble solid phase is settled to the inner wall (outermost) due to the largest centrifuge with the largest specific gravity, Due to the minimum centrifugal force, the light liquid phase is settled farthest (outermost) from the inner wall of the drum. The heavy liquid phase is in the middle. The insoluble solid phase is discharged from the solid phase outlet through the screw pusher with relative differential speed with the drum. The light and heavy liquid phases are separated by different structures in the machine. The heavy liquid phase is discharged through the centripetal pump and the light liquid phase is discharged by gravity, so as to achieve the purpose of three-phase separation of materials.

The light and heavy liquid phases of our three-phase horizontal screw centrifuges are discharged by gravity and centrifugal force respectively, so as to effectively avoid the incomplete separation of materials caused by the mixing of materials. When working, the ordinary three-phase horizontal screw centrifuges often cause incomplete separation due to the unstable components of light and heavy liquid phases, Our three-phase horizontal screw centrifuge can adjust the interface of light and heavy liquid phases according to the changes of material components, so as to achieve the ideal separation effect.

Advantage

At present, three-phase horizontal screw centrifuges are widely used in chemical industry, light industry, medicine, food, papermaking, mining and other industries. And coal tar industry; Petrochemical industry; Fishing powder industry, swill oil industry, electrolytic copper industry, and the separation of oil, water and slag from waste residues in slaughterhouses.

Material Concentration: the material is required to have good fluidity, subject to not affecting the feed. The weight percentage of mixed liquid and solid concentration is generally ≤ 20% (good fluidity, which can be relaxed appropriately).

Material Temperature: the allowable material temperature of this centrifuge is ≤ 90℃

Separation Range

A. When the liquid viscosity is small and the solid particle size is large, the specific gravity difference between solid, liquid and liquid is required to be ≥ 0.05g/cm3 (solid weight and liquid light).

B. When the liquid viscosity is small and the specific gravity difference between solid and liquid is large (specific gravity difference ≥ 1g / cm3), the solid particle is required to be ≥ 0.005mm and the specific gravity difference between liquid and liquid is required to be ≥ 0.05g/cm3.

C. When the liquid viscosity is large or the specific gravity of solid-liquid is small and the solid particles are very fine, the separation effect will be affected or even not applicable.

D. When the solid particles are easy to be damaged, the separation effect will also be affected.

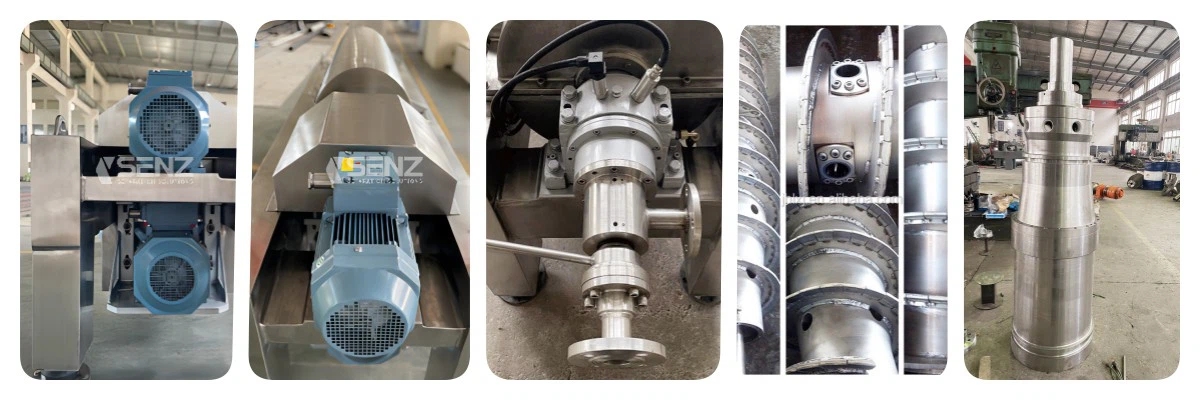

Technical Characteristics

● The centrifuge can clarify, separate and dehydrate 0.002-3mm materials or classify 1um-5um solid particles. It has the characteristics of wide application range, continuous work, large processing capacity, low cost and convenient maintenance. It is the best equipment for solid-liquid separation.

● The differential has high precision, compact structure, stable operation and high safety.

● The main bearing adopts imported bearing to ensure its operation accuracy and convenient operation

.

● The contact parts with materials are made of high-quality stainless steel.

● The whole machine is equipped with a variety of safety overload protection devices to ensure safe production.

● The whole machine system is designed with ordinary type and explosion-proof type to meet different requirements.

● Drum cone structure with large aspect ratio, high speed and multiple angles.

● The screw pusher adopts hard alloy material for hard surface treatment, with strong wear resistance.

● The rack can be designed into low center of gravity, high support and mobile according to the needs of users.

● With BD plate spiral structure, it is suitable for the concentration and dehydration of activated sludge and materials that are difficult to separate.

● According to the actual requirements, it can be equipped with double frequency conversion and intelligent full-automatic control system

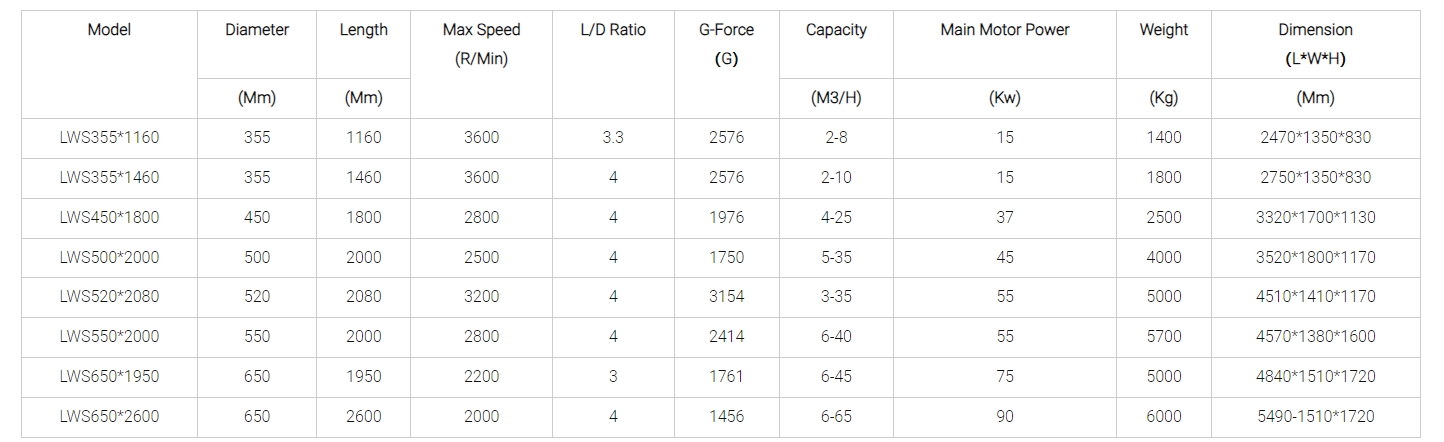

Technical Parameter

Users can reasonably select the working parameters of the centrifuge according to the physical properties of the separated material (suspension), separation requirements, treatment capacity, process requirements and other factors, so as to obtain satisfactory separation effect and economic benefits. Colors and materials can be customized.

Electrical Parts System Description

The main machine of the LW355 centrifuge is composed of a dual motor, dual frequency conversion control, and an energy feedback driven and fully functional control system composed of high-performance frequency converters. The characteristics of this control system are as follows:

a. The main and auxiliary frequency converters are directly connected to the DC bus, which has excellent energy-saving effects and obvious energy-saving effects. When the centrifuge is running, the auxiliarymotor is in a power generation state and operates continuously.

b. The starting is smooth and the speed range is wide, which can meet the treatment of liquids with different solid contents and significantly increase the processing capacity.

c. Both the main and auxiliary motors are controlled by frequency converters, achieving stepless adjustment of the centrifuge drum speed and differential speed within the design range. By adjusting the speed of theauxiliary motor, a reasonable differential speed can be obtained.

Electric Control Functions

→ Startup, shutdown, speed regulation and overload protection of main motor frequency converter ofcentrifuge.

→ Startup, shutdown, speed regulation and overload protection of the frequency converter of the auxiliarymotor of the centrifuge.

→ Automatic protection of centrifuge in case of failure

Control Configuration

a. The main and auxiliary motors of the centrifuge adopt explosion-proof motors, 380V, three-phase, 50Hz.

b. PLC adopts German Siemens products

c. The touch screen adopts German Siemens products

Our Services

Product Consultation:

Expert guidance to help you choose the right Decanter Centrifuge model for your needs.

Customization:

Tailoring equipment to match your specific application requirements.

Quality Assurance:

Ensuring high-quality, reliable Decanter Centrifuges that meet international standards.

Safe Packaging And Timely Shipping:

Secure packaging and timely delivery to your location.

Installation And Commissioning Support:

Assistance with equipment setup and integration into your production process.

Training:

Training sessions for your staff to operate the equipment efficiently.

Spare Parts And Maintenance:

Supply of genuine spare parts and maintenance services for equipment longevity.

Global Reach:

Serving customers worldwide through our network of partners and distributors.

Continuous Improvement:

Commitment to ongoing research and development to enhance equipment performance.

Hot Tags: 3 phase centrifuge, China 3 phase centrifuge manufacturers, suppliers, factory, separate olive oil, spinner 2 oil cleaning centrifuge, Kitchen waste three phase centrifuge, olive oil separation, fat separator, Processing Food Residues Centrifuge