Decanter centrifuges for efficient sludge thickening and dewatering

Handling the 24/7 demanding requirements of modern wastewater treatment plants is a daily challenge. Looking for a well-proven solution which is continuously improved? Wanting to optimize performance while reducing power consumption? Hoping to reduce costs?

Our SHENZHOU decanter centrifuges are the ideal solution for almost all wastewater applications!

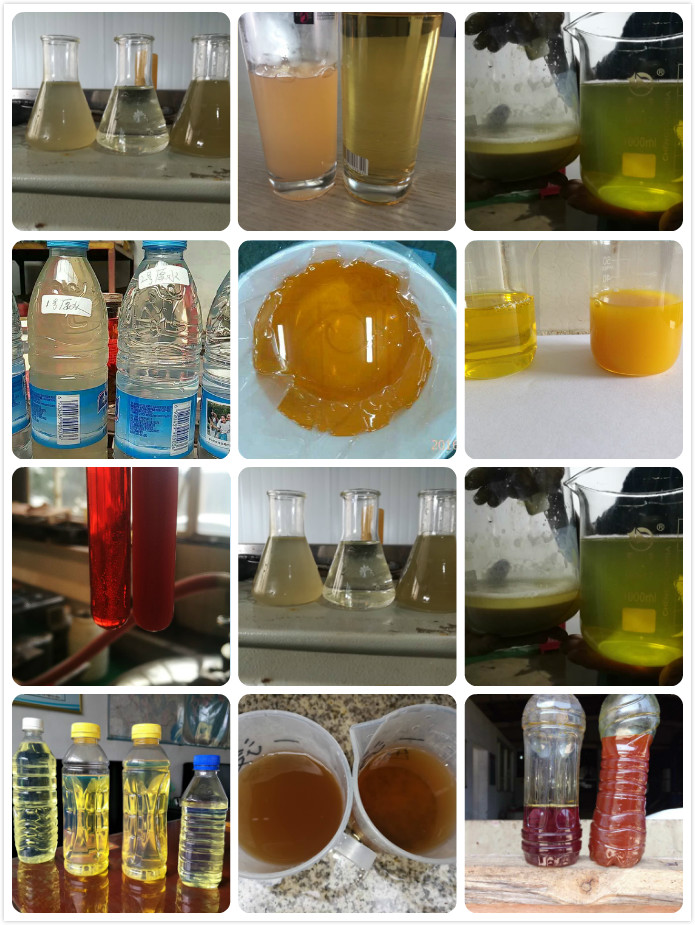

Whatever you are looking for dewatering or thickening, the SHENZHOU decanter centrifuges can handle various flow rates and types of sludge providing you with state-of-the-art separation depending on your input, process and objectives.

SHENZHOU decanter centrifuge range for environment

* SHENZHOU decanter centrifuge LW a reliable solution with high versatility for a wide range of applications.

* SHENZHOU decanter centrifuge LWD, the new decanter which brings best performance in the environmental market.

SHENZHOU decanter centrifuge LW, a reliable solution with high versatility for a wide range of applications!

Decanter centrifuges for efficient sludge thickening and dewatering

Handling the 24/7 demanding requirements of modern wastewater treatment plants is a daily challenge. Looking for a well-proven solution which is continuously improved? Wanting to optimize performance while reducing power consumption? Hoping to reduce costs?

Our SHENZHOU decanter centrifuges are the ideal solution for almost all wastewater applications!

Whatever you are looking for dewatering or thickening, the SHENZHOU decanter centrifuges can handle various flow rates and types of sludge providing you with state-of-the-art separation depending on your input, process and objectives.

* SHENZHOU decanter centrifuge range for environment

* SHENZHOU decanter centrifuge LW a reliable solution with high versatility for a wide range of applications.

* SHENZHOU decanter centrifuge LWD, the new decanter which brings best performance in the environmental market.

* SHENZHOU decanter centrifuge LW, a reliable solution with high versatility for a wide range of applications!

★ High rigidity screw rotor

Centrifuge is a typical double-rotor differential high-speed rotating device. Its separation factor in the protein industry is up

to 3500G, which is the feature of a high-speed centrifuge. The rigidity of the rotor and the control of the unbalance amount are important factors for the stability of operation. [SZ Separation] centrifuge is designed in strict accordance with JB/T 8051-2008 Centrifuge Drum Strength Calculation Specifications. The screw rotor (flexible in high speed state) is put under finite element modal analysis, so that the working speed is far from the first-order and the second-order critical speed to avoid the occurrence of resonance at high speed, ensuring the bearing service life and lowering vibration and noise.

★ Bubble breaker

At the acid-sinking section, the high-speed centrifuge will produce a large amount of bubbles in the separation and liquid

discharging processes. If the bubble is not broken, it is easy to to take out protein. [SZ Separation] centrifuge is internally

set with a bubble breaker, which plays a good role.

★Discharge device for centripetal pump with pressure

The bubble generated during the draining process of the centrifuge is easy to block the drain pipe, causing the fluctuation in the operating current of the centrifuge. [SZ Separation] centrifuge is internally provided with a discharge device for centrifugal pump with pressure to avoid the supernatant being ejected at high speed. The device is particularly suitable for the condition that the liquid phase is directly input into the next section or the next working condition of equipment after separation. For example, in the protein separating process, the soybean milk after first and second extraction enters the acid precipitation tank, and if this device is used, the intermediate transition tank, the transfer pump, and related pipes and instruments are needless.

* Sanitation plan (CIP system)

The centrifuge control system is arranged with a fully automatic cleaning procedure. The multi-step mode of high-speed

cleaning→low-speed cleaning (multi-stage)→high-speed multi-level cleaning ensures that it is thoroughly washed per mechanical cleaning. To avoid human factors, a 360° high-pressure cleaning nozzle is used for the hood, the inner cavity of the base, and the outer surface of the drum.

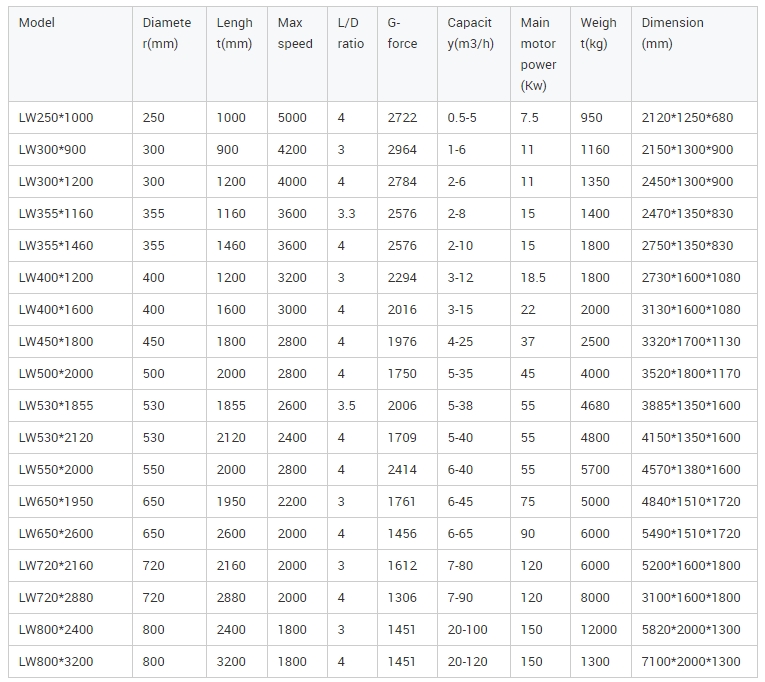

IV. Soybean product high-speed centrifuge parameter table

★ In the industry of soybean products, high-efficiency fully-enclosed high-speed centrifuges are gradually bringing technological innovation in the soybean production line and replacing conventional filter-type equipment. Soybean hulls (similar to medium density) are hard to be removed by common centrifuges. To this end, [SZ Separation] has developed a floating object trap to solve the problem and make the separated soybean milk meet the process production requirements.

Note:The throughput is related to material characteristics;

Control method:

① direct control using an inverter (double-motor double-frequency conversion mode);

② PLO+ touch screen control (intelligent control mode);

Material:AISI321, AISI316, AISI316L SAF2205, etc.

Safety protection:devices for measuring vibration and temperature, emergency stop button, and measures to prevent faulty operation such as hood not being covered.

Main technical features

1. Industrial design

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique technique adopt in main component work-blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-change ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main bearing lubrication system

There are two kinds of lubrication system for specific product models :

A thin oil lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B grease lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1