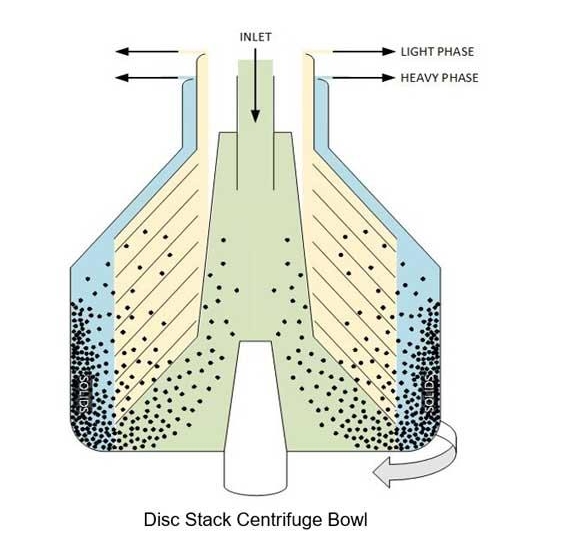

A disc stack centrifuge is a specific kind of centrifugal separator. A set of conical plates (disc stack) is added to the bowl of a centrifugal separator. Addition of the 'disc stack' introduces more settling area. This added surface area speeds up the separation process exponentially.

Industrial Lubricant Recovery Using a Disc Stack Centrifuge

Industrial lubricants - what are they used for?

Oil, grease and other lubricants are used in all types of industries. From lubricating bearings in steel mills, lubricating dies in aluminum wire drawing, lubricating dies in forging, industrial hydraulics and several similar applications.

Causes and types of lubricating oil contamination

There are two types of lubricant contaminants – particle contamination and water contamination. Small particles (< 5µ) in lubricating oil result from metal wear, hard hydrocarbons, combustion residue and airborne dust.

Seepage and condensation cause water contamination. These contaminants affect lubricant properties, its life and can result in high preventive and corrective maintenance costs.

Costs related to lubricant contamination

Broadly, lubricant contamination leads to 3 types of costs.

1. Product quality issues and premature equipment failure.

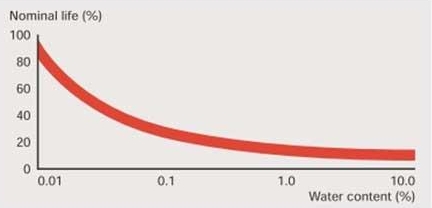

As an example, the following chart shows bearing life as a function of lubricant contamination.

2. High lubricant and disposal costs.

3. Environmental cost of lubricant disposal.

Therefore the reuse of these lubricants is desirable, possible and can prove to be very cost effective. Disc-stack centrifuges are widely used and the machine of choice in industrial lubricant recovery.

Centrifugal Separation - a brief description

Accelerated sedimentation through the use of centrifugal force is Centrifugal Separation. A centrifugal separator multiples the natural force of gravity several thousand times. It uses centrifugal force which is generated by rotation of the fluid.

What is a disc stack centrifuge?

A disc stack centrifuge is a specific kind of centrifugal separator. A set of conical plates (disc stack) is added to the bowl of a centrifugal separator. Addition of the 'disc stack' introduces more settling area. This added surface area speeds up the separation process exponentially.

How does a disc stack centrifuge work?

A disc stack centrifuge separates solids and one or two liquids simultaneously. This is a single continuous process. The centrifuge uses extremely high centrifugal forces to separate the phases.

The denser solids subjected to this force move outwards towards the rotating bowl wall. The less dense liquid phases form concentric inner layers.

The separated solids accumulate around the bowl periphery and are self ejected or manually removed from the bowl.

The separated liquid phase(s) move radially inward towards the bowl center. The liquid(s) overflow through outlet openings in the bowl top.

The clarified liquid phase (or phases) overflow close to the rotating axis, in the outlet area on top of the bowl. In case of 2 liquids, separate outlet chambers let the 2 liquids exit the bowl through independent passages.

In summary, a disc stack centrifuge removes water and solids continuously from the lubricating oil. This means continued production even when large water leaks into the lubricating system. The centrifuge will keep the water content within limits to restore oil properties. Also, it only removes the water without removing the additives.

Disc Stack Centrifuge Performance Data

The following is an example of centrifuge performance on hydraulic oil. This particular oil was in an aluminum extrusion hydraulic press.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1