pore bacteria Tubular Centrifugal Separator.

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

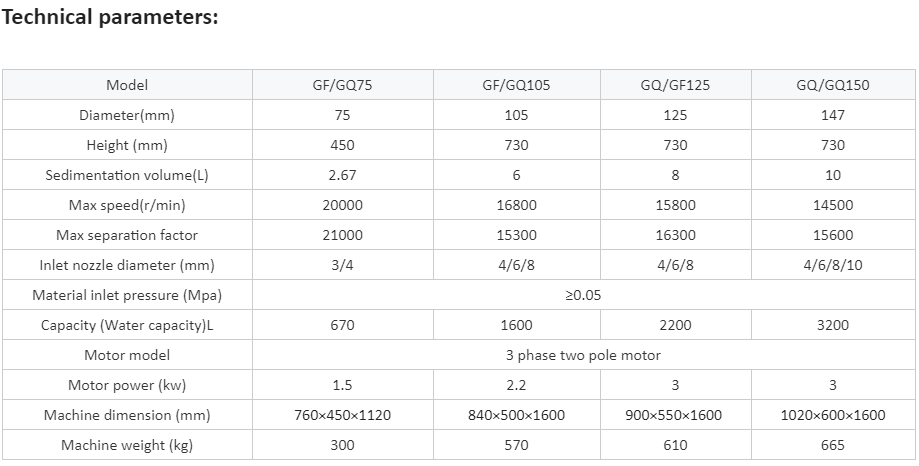

The GQ type is mainly used for a variety of difficult-to-separate suspensions in the separation industry, and is especially suitable for the separation of solid-liquid two-phase separations with thin concentration, fine particles and small specific gravity differences.

The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities.

Tubular separator is a precise separation machinery which fit for the lower solid content suspension liquid and lower small proportion dissolve liquid.It was the key machinery for the pharmaceutical, food, chemical, bio-products and beverage etc.

For various application and machinery operation, the tubular separator is categorized: General purpose, special type (Laboratory model, Chinese Medicine Clarification, Blood separator, Bacteria type, Biodiesel type), Explosionproof type, Fully sealing explosion-proof type, Cooling type, Swing type, Front open type.

Applications:

Tubular Separator is mainly used for separating all kinds of suspension which is difficult to be separated, especially suitable for separation of solid-liquid suspension with light concentration, heavy viscosity, fine particles and very small differential gravity of the two phases.

The possible areas of use are widespread. Tubular centrifuges are used, in the paint and colour industry, in the cooking oil, grease and soap industry, in the chemical pharmaceutical industry(clarification of herbs plants extracts, various medicine liquor, liquid medicine, oral liquid ect).As well as various proteins, algae, fruit gels, and purification of rubber solution, coal tar, graphite, Wax making industry, saponin, pectin, sirup, vaccine mycelia and all kinds of glucose; refining resin.Latex solution, enzyme (SOD) of oxide, various kinds of albumens, the glucoside of the soap, etc. And a specially cooled version of the tubular centrifuge can also be used for the fractionation of human blood.

Working principle:

The liquid (suspension or liquid mixture) is, as a rule, fed in at the bottom, rises in the drum and leaves the upper end of the drum purified (for a suspension) or separated (in the case of a liquid mixture.The centrifugal effect (depending on the diameter of the drum) can be up to 21,000g.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1