Centrifugation, an efficient solution to solve your dewatering and thickening tasks Centrifugation is a mechanical separation process in which two or more materials are separated using centrifugal forces. The demands of a centrifuge depend strongly on the specific application (e.g. flow rates and solids load), the material characteristics (e.g. particle size and abrasion behavior), and the operating environment (e.g. explosion-proof design)

More details you can contact us freely!

Each machine in the SHENZHOU decanter centrifuge family benefits from an application-specific design.

Whether your goal is to separate solids from liquids, two liquids from each other, or even to accomplish both tasks at the same time, our application specialists have an optimal design for you.

Thanks to decades of experience with continuously evolving machine designs, our top-of-the-class decanter centrifuges ensure reliable and efficient performance.

The sedimentation process can also reach higher flow rates in a continuous mode. Wide variations in feeding parameters can also be accepted. In sedimentation processes, consumables, such as filter media in filtration processes, are not used. Better capture rates can be achieved by centrifugal sedimentation as washing cycles in the filtration process could reduce the final product capture rate. Sedimentation processes are better able to handle complex products, especially compressible ones, which are difficult to separate in filtration processes. Washing of sedimentation equipment is easier than with filtration equipment because the filtration equipment’s wash water is under pressure, thus larger quantities are used.

High-performance materials: Best protection against wear for extended decanter life cycle The SHENZHOU decanter centrifuge LWD is manufactured with advanced wear-resistant materials for a long, continuous life cycle. A variety of materials ensures that your operations are able to withstand high temperatures, heavy-duty products, and corrosive products. • To protect the bowl, the inner surface has strips or grooves, depending on machine size and application. Bowl outlets are protected with easily replaceable bushings. • To protect the screw conveyor, the inside of the feed chamber is coated with tungsten carbide spray or protected Inlaid cemented carbide. Feed chamber outlets are equipped with replaceable bushings, and the screw conveyor blade has replaceable tiles made of tungsten carbide.

• Good wear protection is a strategic, long-term investment with a guaranteed return. • To protect the solids casing, the receiving surface is a thick stainless steel plate with polyurethane or tungsten carbide spray coating, depending on the application. • Exchangeable wear parts mean fewer repairs and less downtime, both of which lead directly to reduced maintenance costs

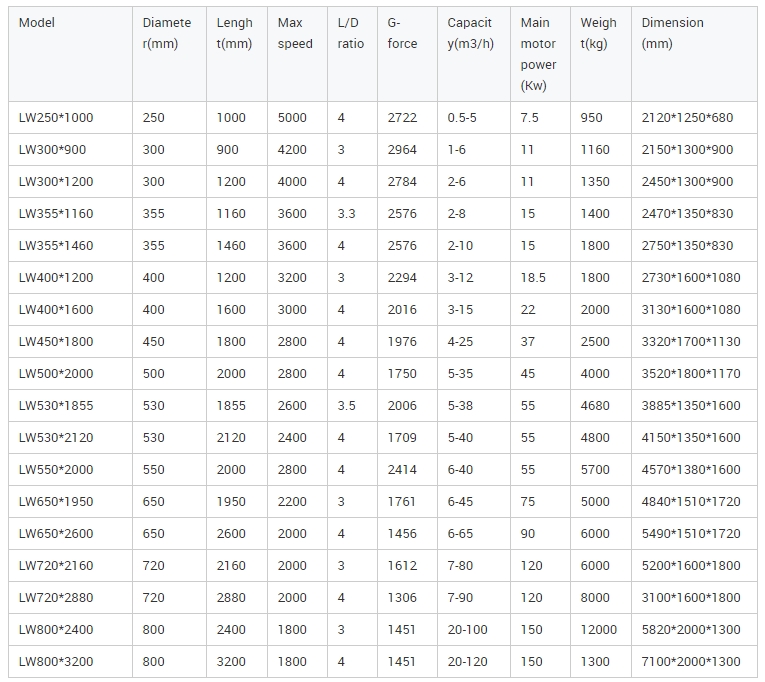

Technical Parameter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1