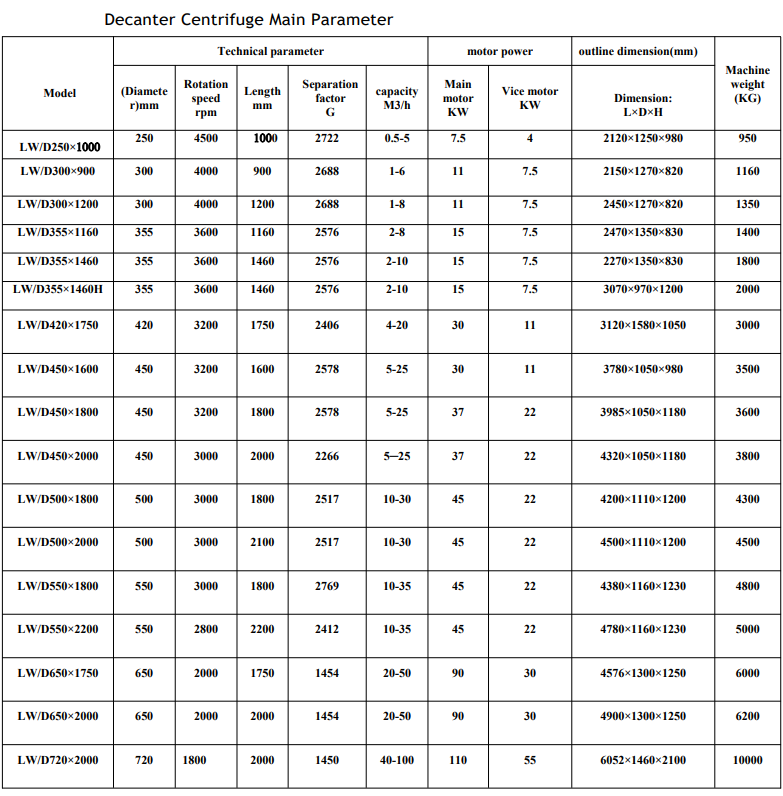

Decanter centrifuge is a kind of horizontal screw discharged, continuous operation settlement equipment. This equipment is mainly used to remove the solid particles in suspension to get clear liquid, or to remove the larger solid particles in the feeding liquid, and to treat the solid particles of materials to get dehydration effect. It is also divided into two-phase separation and three-phase separation centrifuges. Two-phase mainly refers to a liquid and a solid; The three-phases can be liquid-liquid-solid separation or solid-solid-liquid separation.

Decanter centrifuge is mainly composed of rotating parts assembly, power transmission system, overload protection system, frame and shell, feeding pipe and electrical system. The rotating part assembly is composed of bowl, screw conveyor, gearbox and other parts, which is horizontally supported on the base by two main bearing seats.

The screw conveyor assembly is composed of core tube, accelerator, screw flight, welded. It is coaxially placed in the bowl through the bearings on the half shafts at both ends, and connected with the gearbox through the spline shaft.

The power transmission is driven by an electric motor, which drives the bowl to rotate through a belt and a main pulley. The auxiliary drive is driven also by a motor, which is connected by a belt, and the gearbox pulley and overload protection device drive the gearbox input shaft to rotate.

![]()

Working Principle of Horizontal Decanter Centrifuge

The raw materials are pumped or self-flowing into the horizontal decanter centrifuge. Under the centrifugal force generated by high-speed rotation of the bowl, the solid and liquid components are stratified due to different densities, so as to realize solid-liquid separation.

The solid particles with high density settle on the inner wall of the bowl and move towards the outlet of the cone section of the bowl under the push of the screw conveyor. The solid particles are further dehydrated under the bidirectional extrusion between the cone section of the bowl and the spiral blade to reduce the solid moisture content.

The separated liquid phase overflows out of the working chamber and is collected by the collecting chamber and then discharged out of the centrifuge.

In the continuous development and improvement of horizontal decanter centrifuge, there are many advantages: for example, the use of wear-resistant materials and cemented carbide blocks enhances the wear resistance, prolongs the service life and improves the separation effect; A baffle is installed at the transition between the straight section and the cone section of the screw to further compress the solid phase and dry the discharged solid phase. The depth of the liquid pool is deep, the liquid phase in the bowl clarification time is long, and the discharged liquid phase is more clear.

At present, horizontal decanter centrifuges are widely used in various industrial fields, and horizontal decanter centrifuges can be used in many places. Such as petroleum, coal chemical industry, steel, resin, food, kitchen, fermentation, medicine, tunnel engineering, sewage treatment, mining and other fields. Its powerful separation processing capacity and good separation effect have been highly praised by people in the industry!

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1