As a highly precise equipment, it is essential to grasp the selection criteria when choosing a centrifuge. Here we introduce to everyone

The factors to consider when choosing a centrifuge are as follows.

When choosing a centrifuge, the main factors to consider include the following: (1) density, viscosity, and surface tension of the liquid phase material

power. (2) The separation of materials mainly involves solid or liquid phase materials. (3) Particle size, density, and hardness of solid materials

Degree. (4) The flammability and explosiveness of materials. (5) Affinity, concentration, and all charge properties (positive charge) of solid and liquid phase materials

(6) Sludge properties: The higher the organic matter content and oil content of the sludge, the worse the dewatering performance. (7) The material's

rate of recovery. (8) The volatility of materials. (9) The corrosiveness of materials. (10) Speed difference: Its size not only affects processing energy

Strength also affects the processing effect. (11) When solid materials are crystalline products, it is required that the degree of crystal damage during separation be low

There are special requirements for the structure and unloading methods of the equipment. (12) Sludge treatment capacity, for a certain specification of centrifuge, output

The water efficiency changes with the increase of sludge treatment capacity. In order to achieve the expected goal, select the appropriate machine with the appropriate treatment capacity based on the sludge volume

Type is very important.

As long as you can grasp these 12 factors when choosing a centrifuge, you can choose a device that is more suitable for yourself,

It also plays an important role in the development of enterprises

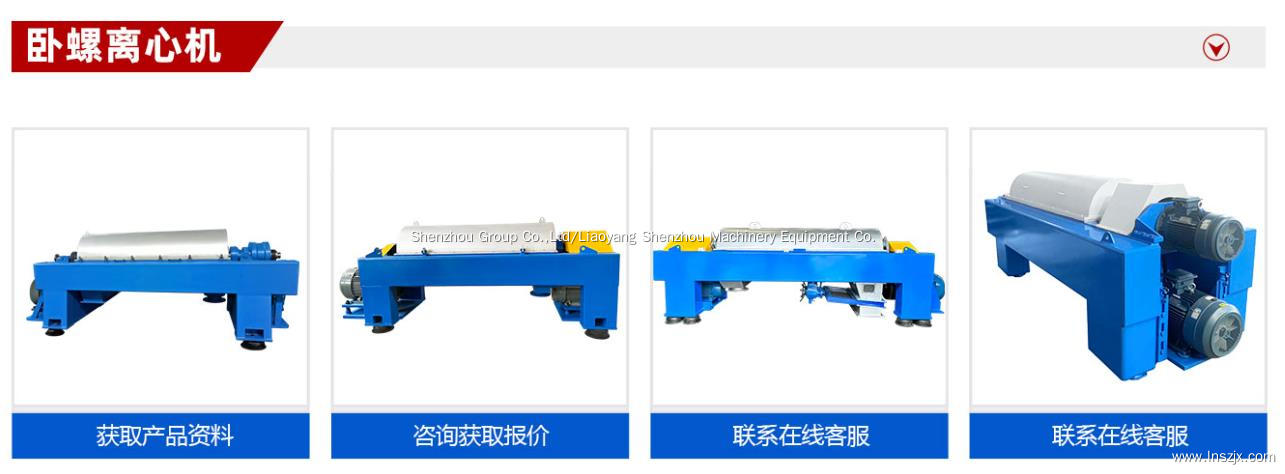

As a highly precise equipment, it is essential to grasp the selection criteria when choosing a decanter centrifuge.

Here we introduce to everyone

The factors to consider when choosing a centrifuge are as follows.

When choosing a centrifuge, the main factors to consider include the following: (1) density, viscosity, and surface tension of the liquid phase material

power. (2) The separation of materials mainly involves solid or liquid phase materials. (3) Particle size, density, and hardness of solid materials

Degree. (4) The flammability and explosiveness of materials. (5) Affinity, concentration, and all charge properties (positive charge) of solid and liquid phase materials

(6) Sludge properties: The higher the organic matter content and oil content of the sludge, the worse the dewatering performance. (7) The material's

rate of recovery. (8) The volatility of materials. (9) The corrosiveness of materials. (10) Speed difference: Its size not only affects processing energy

Strength also affects the processing effect. (11) When solid materials are crystalline products, it is required that the degree of crystal damage during separation be low

There are special requirements for the structure and unloading methods of the equipment. (12) Sludge treatment capacity, for a certain specification of centrifuge, output

The water efficiency changes with the increase of sludge treatment capacity. In order to achieve the expected goal, select the appropriate machine with the appropriate treatment capacity based on the sludge volume

Type is very important.

As long as you can grasp these 12 factors when choosing a centrifuge, you can choose a device that is more suitable for yourself,

It also plays an important role in the development of enterprises

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1