The working principle of the horizontal spiral settling centrifuge is that the slurry mixture enters the drum through the feed pipe and spiral discharge port. Under the centrifugal force generated by the high-speed rotation of the host, solid particles with a high density deposit on the inner wall of the drum. The spiral blades that move relative to the drum continuously scrape off the solid particles deposited on the inner wall of the drum and push them out of the slag discharge outlet. The separated clear liquid flows out of the drum through the opening of the weir plate. The relative motion between the spiral and the drum is achieved by a differential. The differential housing is connected to the drum, the output shaft is connected to the screw, and the input shaft is connected to the auxiliary motor. The main motor drives the rotation of the drum and also drives the rotation of the differential housing. Due to the connection between the input shaft and the auxiliary motor, the auxiliary motor generates braking torque, which drives the planetary gears to operate according to the designed transmission relationship and transmits the torque to the screw in a certain proportion, achieving continuous separation of materials in the horizontal spiral settling centrifuge.

Product Description:

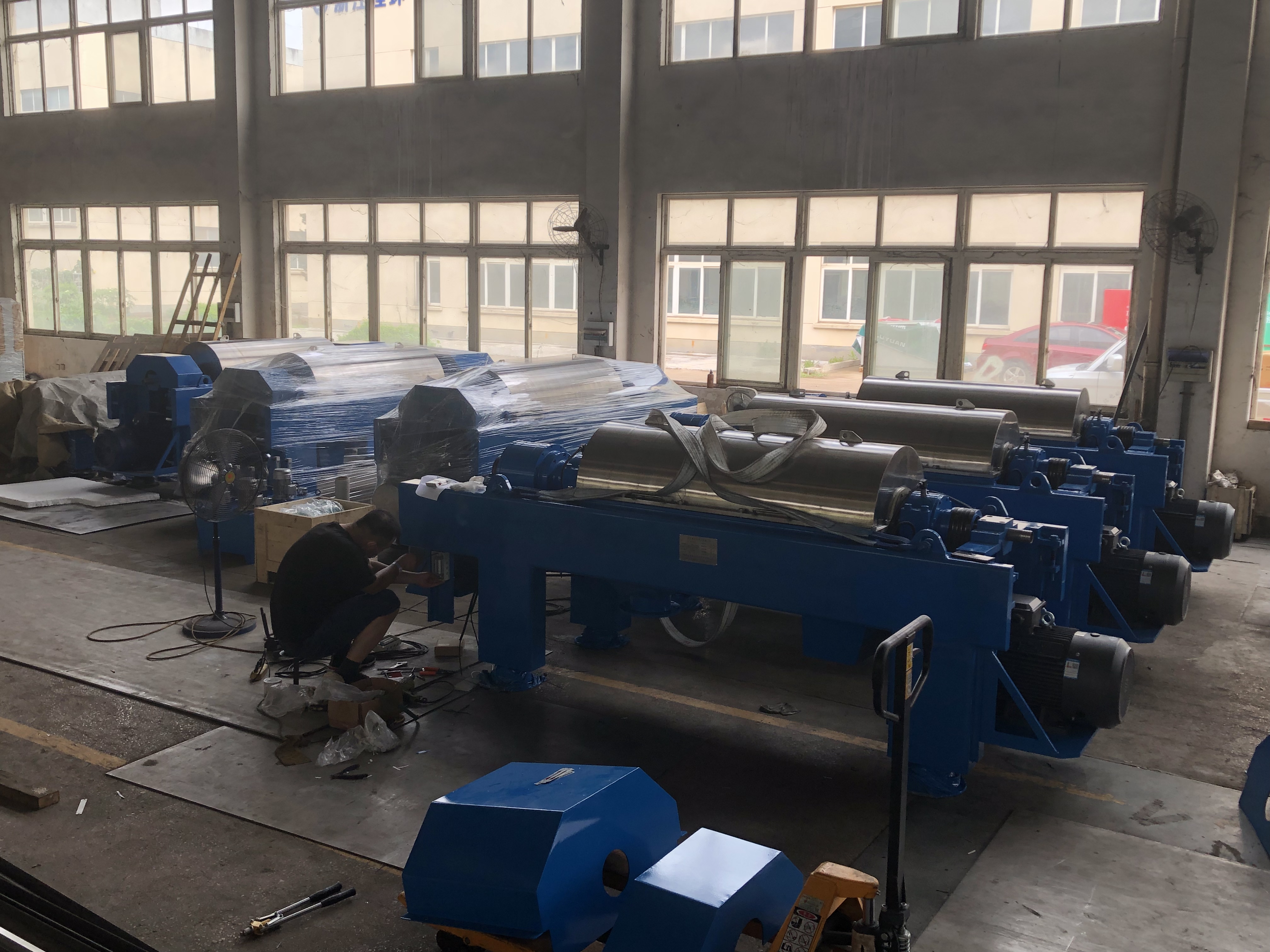

Horizontal spiral centrifuge is one of our company main products. According to the requirement of the material used, we design the horizontal spiral centrifuge with one motor, two motors driving. At the same time, we design two motors separately on both sides of the machine and motors on the same place of the machine. We also develop three column horizontal spiral centrifuge, used in the separation of coal tar oil, water, slag in the industry, in petrochemical in the separation of oil, water, slag.

Main motor drive at full speed rotating drum, material put into spiral continuously by feed tube, evenly distributed to the spiral discharging port. Under centrifugal force, solid content settles to the drum wall and is pushed out cone drum slag notch by the spiral pusher. Liquid is overflow along the spiral to the drum big end. It form big end set out liquid and small end set out solid.

Tenchical parameters:

Type: LW450

Drum diameter: 450mm

Drum speed: 3000r/min

Drum length: 1950mm

Separation factor: 1952

Ratio of L/D: 4.3

Main EL-Motor Power: 22-.37kW

Production capacity 5-50m3/h

Electric control box: PLC double frequency conversion touch screen control

Weight: 2600kg

working principle:

Separation takes place in a horizontal cylindrical bowl equipped with a scroll conveyor. The processing material is fed into the bowl through a stationery inlet tube and is smoothly accelerated in the accelerate chamber. Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl.

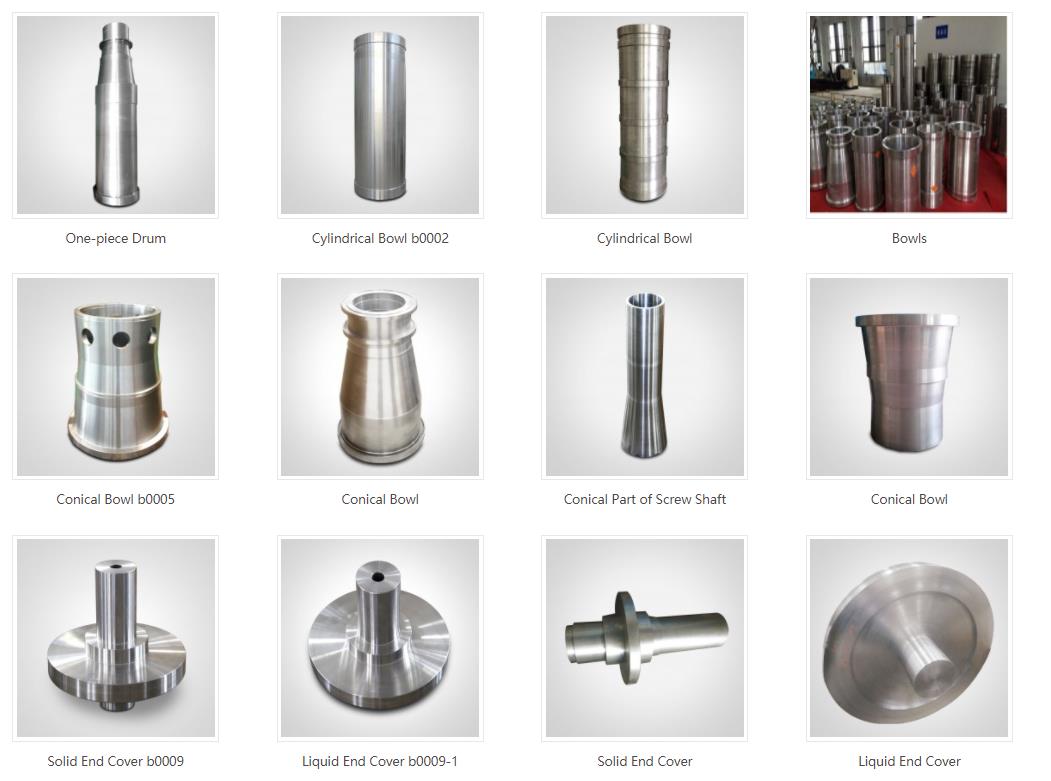

Main parts :

The major parts are: ①rotary drum ②spiral feeder ③engine base ④stainless steel cover ⑤stainless steel cover ⑥absorber ⑦electrical machine.

Application:

Currently, our three-phase decanter centrifuges are used in the separation of olive oil , soybean oil , oils,

water and slags / dregs in the coal tar industry, the petrochemical industry, the fish powder industry, the swill

oil industry, the electrolytic copper industry, and the waste scraps in the slaughter houses.

Packing and shipping:

Machine freight by truck or container. Container machine be fixed by steel wire, to make sure all of them not be damage by transport jolt.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1