LWL series has hundreds of cases in the waste salt treatment industry, including sodium chloride, sodium sulfate, ammonium

chloride, ammonium sulfate, ferric chloride, and ferrous chloride. In addition, we have rich experience in plant extraction (tea,

ginkgo, iron powder, kudzu root, hemp leaves, etc.), magnesium sulfate, copper sulfate, sodium gluconate, sodium metabisulfite,

marine snowmaking, and other industries. Welcome customers from related industries to inquire.

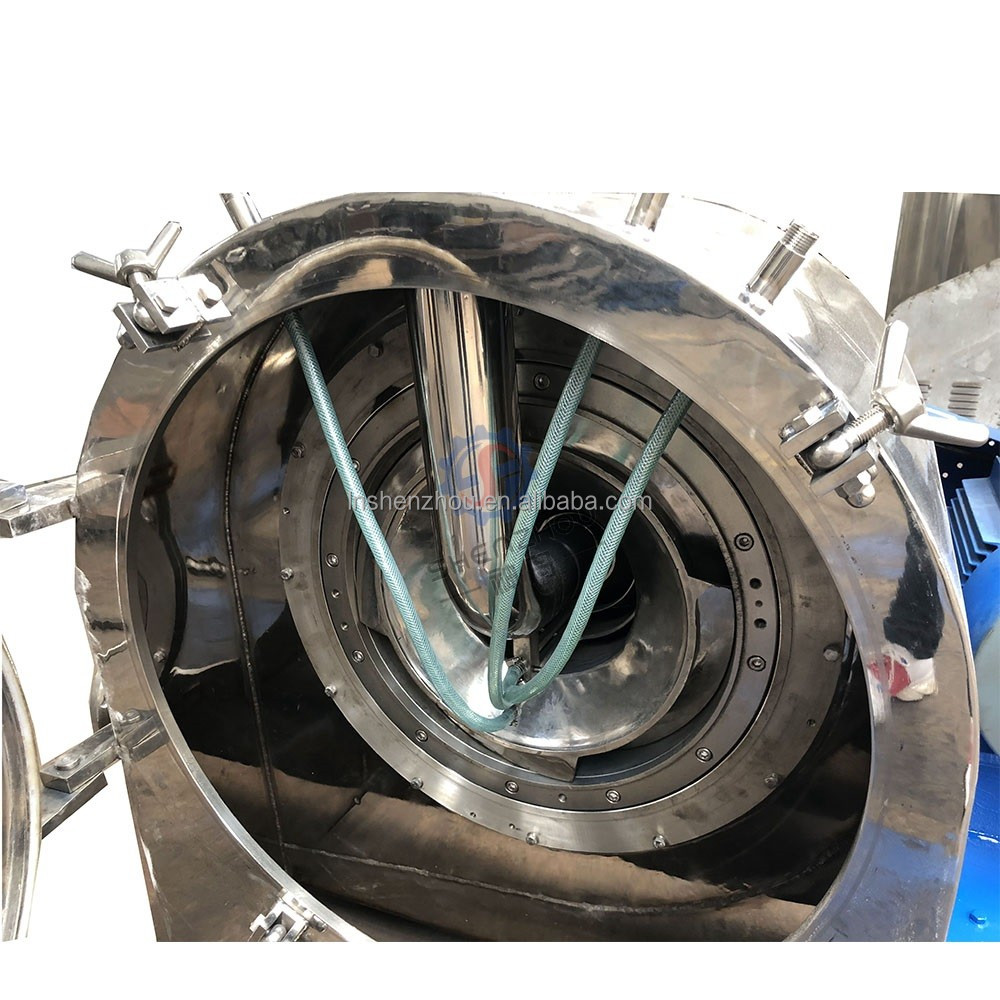

LWL Industrial Horizontal Spiral Screen Worm centrifuge machine

LWL series centrifuge is a horizontal screw discharge and continuous operation filtering centrifuge. Capable of continuous feeding, separation, washing and unloading at full speed.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Main Characteristics

Continuous operation, screw discharging and large capacity. High dehydration rate of solid phase,good washing effect and high efficiency.Tight structure and convenient operation and maintenance.

Processing parameters

Average particle size : 50-1000 um

Feed solid concentration > 5% by weight

Solid throughput : up to 15 t/h

Continuous operation, screw discharging and large capacity. High dehydration rate of solid phase,good washing effect and high efficiency.Tight structure and convenient operation and maintenance.

Processing parameters

Average particle size : 50-1000 um

Feed solid concentration > 5% by weight

Solid throughput : up to 15 t/h

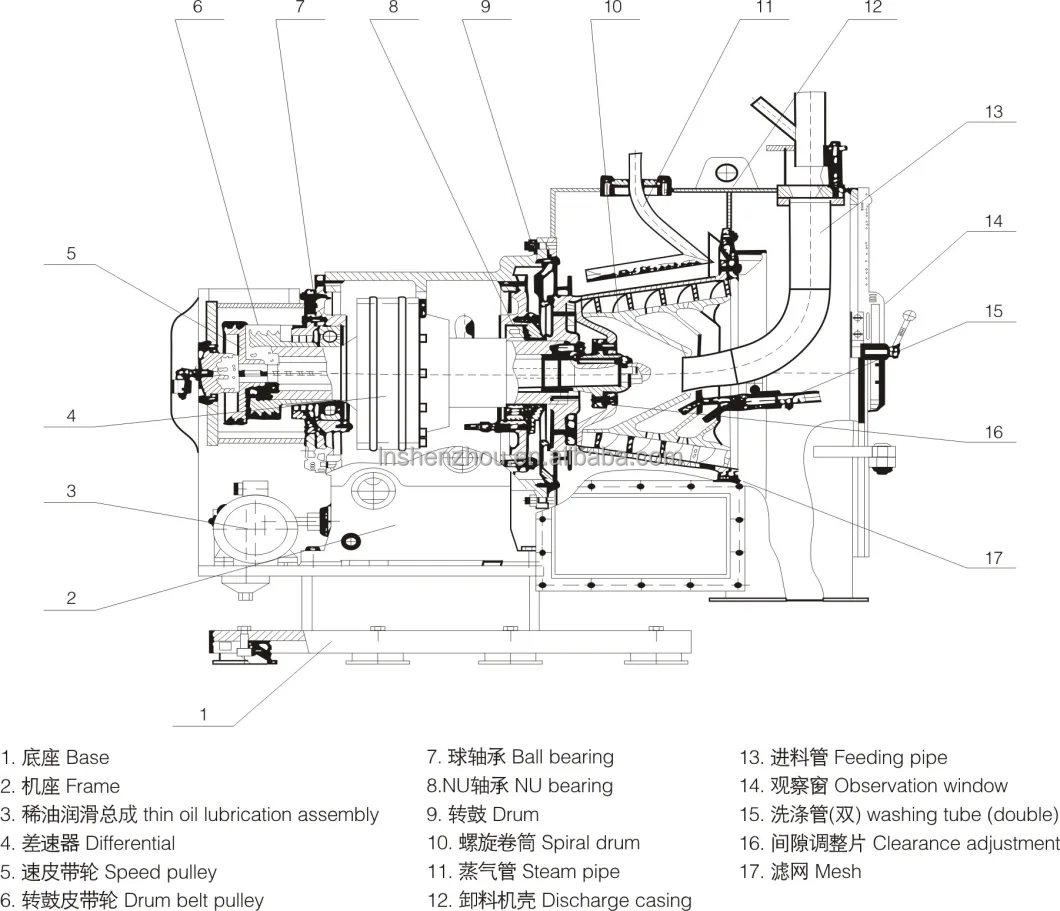

1. Base

2. Frame

3. thin oil lubrication assembly

4. Differential

5. Speed pulley

6. Drum belt pulley

7. Ball bearing

8. NU bearing

9. Drum

10. Spiral drum

11. Steam pipe

12. Discharge casing

13. Feeding pipe

14. Observation window

15. washing tube (double)

16. Clearance adjustment

17. Mesh

2. Frame

3. thin oil lubrication assembly

4. Differential

5. Speed pulley

6. Drum belt pulley

7. Ball bearing

8. NU bearing

9. Drum

10. Spiral drum

11. Steam pipe

12. Discharge casing

13. Feeding pipe

14. Observation window

15. washing tube (double)

16. Clearance adjustment

17. Mesh

Features

1. Strong pertinence to materials, the crystal size is between 0.05-10mm

2. Continuous operation, Screw unloading, Large production

3. The solid phase has a low moisture content, good washing effect, and high separation efficiency

4. Dedicated filter screen, material optional, filter screen thickness up to 0.5mm, longer service life

5. Stepless speed regulation of drum speed

6. Simple and reliable lubrication

7. Compact structure, easy operation, and maintenance

8. Safety protection: speed detection, oil-free protection, motor overload and overheat protection, spiral zero differential

protection.

★LWL series has hundreds of cases in the waste salt treatment industry, including sodium chloride, sodium sulfate, ammonium chloride, ammonium sulfate, ferric chloride, and ferrous chloride. In addition, we have rich experience in plant extraction (tea, ginkgo, iron powder, kudzu root, hemp leaves, etc.), magnesium sulfate, copper sulfate, sodium gluconate, sodium metabisulfite, marine snowmaking, and other industries. Welcome customers from related industries to inquire.

The improvements made by SHENZHOU in ammonium sulfate, ammonium chloride, ammonium thiocyanate, sodium chloride, and other waste liquid salt extraction equipment:

1. The feeding pipe device is improved, the cloth is more uniform, and the equipment operation is more stable;

2. The lubrication system is improved, the lubrication is more adequate and reasonable, and the bearing weight is increased;

3. Improve the bearing sealing system and adopt labyrinth oil seals to prevent mother liquid from entering the lubrication system;

4. The drum spiral is treated with nitriding and wear-resisting, and the service life is longer.

5. The discharging system is improved, and a scraper device is added to prevent the silo from accumulating.

2. Continuous operation, Screw unloading, Large production

3. The solid phase has a low moisture content, good washing effect, and high separation efficiency

4. Dedicated filter screen, material optional, filter screen thickness up to 0.5mm, longer service life

5. Stepless speed regulation of drum speed

6. Simple and reliable lubrication

7. Compact structure, easy operation, and maintenance

8. Safety protection: speed detection, oil-free protection, motor overload and overheat protection, spiral zero differential

protection.

★LWL series has hundreds of cases in the waste salt treatment industry, including sodium chloride, sodium sulfate, ammonium chloride, ammonium sulfate, ferric chloride, and ferrous chloride. In addition, we have rich experience in plant extraction (tea, ginkgo, iron powder, kudzu root, hemp leaves, etc.), magnesium sulfate, copper sulfate, sodium gluconate, sodium metabisulfite, marine snowmaking, and other industries. Welcome customers from related industries to inquire.

The improvements made by SHENZHOU in ammonium sulfate, ammonium chloride, ammonium thiocyanate, sodium chloride, and other waste liquid salt extraction equipment:

1. The feeding pipe device is improved, the cloth is more uniform, and the equipment operation is more stable;

2. The lubrication system is improved, the lubrication is more adequate and reasonable, and the bearing weight is increased;

3. Improve the bearing sealing system and adopt labyrinth oil seals to prevent mother liquid from entering the lubrication system;

4. The drum spiral is treated with nitriding and wear-resisting, and the service life is longer.

5. The discharging system is improved, and a scraper device is added to prevent the silo from accumulating.

Applications:

Mainly used for the separation and dehydration of liquid-solid two-phase suspensions with solid particle size of 0.05-10mm. It is used in chemical industry, food, chemical fiber, mining, metallurgy, light industry and other industries.

Typical application materials: adipic acid, ammonium thiosulfate, fruit stone, mycelium, mirabilite, soda, arsenic azole, oxalic acid, sodium acetate, gunpowder, aspirin, polystyrene, reclaimed rubber, metal slag, cellulose wool, lactose, borax, plastic particles, vegetables, pesticides, zinc sulfate, Date stones,Polyvinylacohol ,Sodium Thiosulphate ,Copper Sulphate ,Potash , Tarteric Acid ,Crystal Soda ,Polash Alum ,Potassium Monochromate Plastic granules, Glacial Acetic Acid ,Potassium Chloride ,Plexig lass Beads,Disodium Phosphate,Dinitro Methylarlin,PVC,Potash Solvent Residue ,Vegetable extractS ,Trisodium ,DMT, DMT from Methanol Dinitro Methlyanilin ,Pesticide ,vegeta bles ,Potassium Pensuphate,Potassium Bicarbonate ,hops from dichlorc methaRe ,sodium ca rbonate,Monosod iumphasphate ,Sodium Nitrate,Finely chopped onions ,Potassium Bichromate ,Potassium Phosphate ,Potassium Sulphate ,Polyethylene,etc.

Specification

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap