2 Phase Centrifuge for Animal Blood Separation Equipment

Product features

The 2 Phase Centrifuge for Animal Blood Separation Equipment is a highly efficient machine designed for separating blood plasma and cells from various animals such as pigs, cows, sheep, and chickens. Made with stainless steel contact parts meeting GMP requirements in the pharmaceutical industry, this high-speed separator features a main body, driving device, bowl collecting pan, and liquid-in bearing seats for optimal performance. The GFXY model effectively separates various emulsions with slight gravity differences, making it ideal for liquid-liquid separation and liquid-liquid-solid separation with minimal foreign matter for applications like plasma and cell separation.

Team strength

Team strength is crucial in the development and success of the 2 Phase Centrifuge for Animal Blood Separation Equipment. Our dedicated team of scientists, engineers, and technicians work collaboratively to ensure the highest quality and efficiency of our product. Their expertise in centrifuge technology, animal blood separation techniques, and product design allows us to deliver a reliable and cutting-edge equipment. With a strong emphasis on innovation and continuous improvement, our team is constantly striving to enhance the performance and capabilities of our centrifuge for the benefit of our customers. Trust in our team's strength to provide you with a superior animal blood separation solution.

Enterprise core strength

Our 2 Phase Centrifuge for Animal Blood Separation Equipment showcases the strength of teamwork in delivering exceptional performance and efficiency. Our product is designed and engineered by a dedicated team of experts who understand the importance of precise blood separation for veterinary medicine. With a focus on quality and reliability, our team works together to ensure the centrifuge meets the highest standards in animal healthcare. From the initial design phase to testing and production, our team collaborates seamlessly to bring you a product that is both innovative and reliable. Trust in our team's strength to deliver top-notch animal blood separation equipment for your veterinary practice.

We are specialized in manufacturing Centrifuge of Animal Blood for Pharmaceutial or Animal Feed Industry, etc. for over many years. Technology is the core competitiveness of a company. Since established, we have been researching and developing high-level technologies to make sure highly efficient manufacturing process.It covers a wide range and is commonly seen in the application field(s) of Separation Equipment. Thanks to the multiple characteristics that have been tested by our QC inspectors,Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge has a wide application in different fields mainly including Tubular centrifuge.We hold a firm belief that the broad application of the product will drive the industry to develop and advance rapidly.

| Place of Origin: | Liaoning, China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Hot Product 2019 | Warranty of core components: | 1 Year |

| Core Components: | Bearing, Motor | Brand Name: | Shenzhou |

| Voltage: | Customerized | Power: | Model choosing |

| Weight: | 460kg | Dimension(L*W*H): | 850*750*1650mm |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops, centrifuge, animal feed factory, Blood plasma factory | Showroom Location: | None |

| After-sales Service Provided: | Video technical support, Online support | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | None | Certification: | GMP/CE |

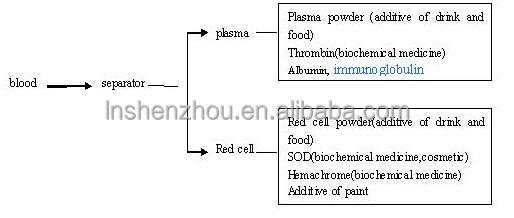

The blood separator is one kind of tubular separator. This machine is the improved one on the base of the original separator and through experiment again and again. This kind of machine can be extensively used in separating blood plasma and cell of pig, cow, sheep and chicken etc.

The main feature of it is the high yield and the rate of broken blood cell can be reduced to the lowest extent. The contact part between the separator and material is made of stainless steel which can meet the requirement of GMP in medicine making industry.

It is high speed separator. It has better separation. The separator is consisted of main body, driving device, bowl collecting pan and liquid-in bearing seats. The upper of the bowl is flexible main shaft and the lower of it is damp floating. The main shaft is connected with a driven wheel by the coupling seat with the buffer. The power is transmitted to the driven wheel by the motor through the transmission belt and the tensioner to make the bowl rotate around its axis at an over speed and form a strong centrifugal force field. The product sprays into the liquid inlet from the bottom and liquid is forced to flow upward along the inner wall of the bowl and then is separated into different layers according to different density.

GFXY model is a separating equipment where there the liquid phase of large density is formed into outer ring and the liquid phase of small density is shaped into inner ring, to flow to the top of bowl, to be discharged out from their respective liquid outlets.

The micro solids settle on the wall of the bowl and are to be manually dumped after the machine is shut down.

GFXY: It is used for separating various emulsion, especially adaptable for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as separation of various oil and micro powder, extract liquid from plants, separation of plasma and cell.

Model | GFXY1 | GFXY2 |

Diameter(mm) | 105 | 112 |

Height (mm) | 730 | 730 |

Sedimentation volume(L) | 6 | 7 |

Max speed(r/min) | 16800 | 15800 |

Max separation factor | 15300 | 16300 |

Inlet nozzle diameter (mm) | 4/6/8 | 4/6/8 |

Material inlet pressure (Mpa) | ≧0.05 | ≧0.05 |

Capacity of fresh blood(L/H) | 300-400 | 400-600 |

Motor model | 3 phase two pole motor | 3 phase two pole motor |

Motor power (kw) | 2.2 | 3 |

Machine dimension (mm) | 600*1000*1600 | |

Machine weight (kg) | 490 | 510 |

We can provide CE, ISO 9001, etc

2. What is the warranty period of the equipment?

Normally 1 year warranty.

3. Can we visit your factory?

Of course, we sincerely invite you to visit, If it's not convenient for you to come to our factory, you can also visit by

telephone video conference.

4. What's payment you accept?

A4: T/T, Western Union, L/C, Ali Pay, etc

5. Can it be customized?

Of course, our equipment can be customized according to the actual requirements of customers.