Our 2 Phase Centrifuge offers a high-efficiency manufacturing solution with its advanced technology and cutting-edge design. Its superior performance and precision ensure optimal results in various industries, saving time and resources. The product features include a user-friendly interface, high-speed operation, and durable construction, making it a top choice for companies looking to streamline their production processes.

At the heart of our 2 Phase Centrifuge is a team of dedicated engineers and technicians who have collaborated to create a high-efficiency manufacturing solution. Our team's strength lies in their collective expertise in centrifuge technology, process optimization, and customer satisfaction. With a focus on innovation and continuous improvement, our team is committed to delivering a product that meets the highest standards of quality and performance. By leveraging our team's knowledge and experience, we are able to provide a solution that streamlines manufacturing processes, increases productivity, and maximizes efficiency for our customers. Trust in our team's strength to propel your business forward.

Team Strength: Our 2 Phase Centrifuge is backed by a team of skilled engineers, designers, and manufacturing experts who work seamlessly together to deliver a high-efficiency solution for your manufacturing needs. Our team's strength lies in their collective experience, innovative thinking, and commitment to quality, ensuring that every component of our centrifuge is designed and manufactured to the highest standards. With a focus on collaboration and communication, our team is dedicated to providing you with a reliable and cost-effective manufacturing solution that will help streamline your processes and improve your overall productivity. Trust in our team's expertise to take your manufacturing operations to the next level.

Product Description

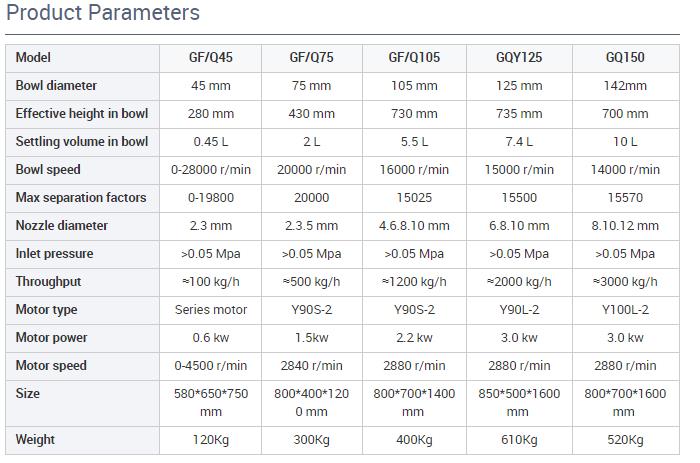

Product parameters

service

fAQ

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1