The 2 Phase Centrifuge: High-Performance Pectin Extraction Machine is designed with advanced technology to efficiently extract pectin from fruits. Its high-performance capabilities allow for quicker and more precise extraction, saving both time and resources. The machine's reliable and durable design ensures consistent results, making it a valuable tool for businesses in the food processing industry.

We serve you with our 2 Phase Centrifuge, a high-performance pectin extraction machine designed to streamline your production process. Our advanced technology ensures efficient separation of solids and liquids, resulting in increased productivity and higher quality pectin extract. With precision engineering and user-friendly operation, we prioritize your operational needs, delivering a reliable and cost-effective solution for your business. Trust in our commitment to excellence and let us serve you with a product that exceeds expectations. Experience the difference with our 2 Phase Centrifuge and elevate your pectin extraction process to new heights.

At our company, we serve our customers with the highest quality 2 Phase Centrifuge for high-performance pectin extraction. Our cutting-edge machine is designed to deliver efficient and effective results, allowing you to extract pectin with ease. We understand the importance of delivering top-notch performance and reliability in our products, which is why our centrifuge is built to last. With a focus on customer satisfaction, we are dedicated to providing excellent service and support to ensure that your extraction process runs smoothly. Trust us to serve you with the best extraction machine on the market.

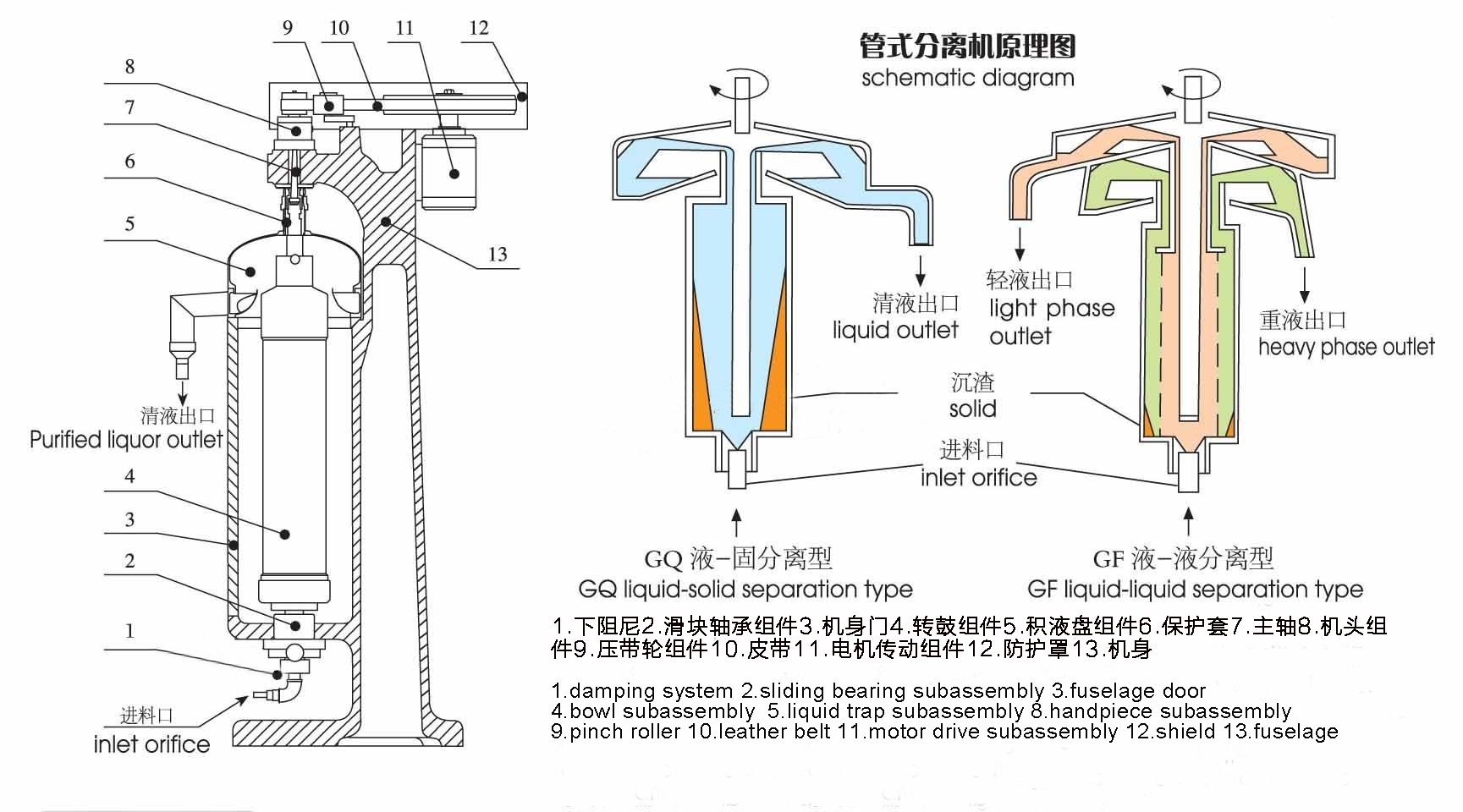

The Feature of Tubular centrifuge

The centrifuge has high performance of separate factor, high capacity, and account for small area and easy to handle, it has t types, one is GQ two phase that can separate solid from the liquid, another is GF series, which can separate the water, solid from the oil.

GF model: Liquid with big density forms the outer liquid circle, while liquid with small density forms the inner circle. Then liquid will flow out of the upper outlet accordingly, and those little solid will be deposited on the drum wall, and be removed by manual after machine stops.

GQ model: Solid particles with big density are gradually deposited on the drum's inner wall, and forms sediment layer, after machine is stopped, is removed by manual. While the clarified liquid flows out through the outlet on the upper of the drum.

Product application

The tubular centrifuge is suitable for solid-liquid separation with small concentration, high viscosity, fine solid phase particles and small difference in solid-liquid gravity. It is mainly used in biomedicine, traditional Chinese medicine preparation, fermentation bacteria liquid separation, health food, beverage, animal and plant. Protein pectin extraction separation, liquid-solid separation of food health products, plant pigments, fine chemicals,ink and other industries. It is an ideal equipment for dynamic continuous separation by centrifugation. The separation factor of high-speed tubular centrifuge is 15900~16700xg, and the diameter of separated small particles is 0.5μm. Therefore, the difference in weight between liquid and solid is small, the solid particle size is fine, the content is low, the medium is corrosive and the materials are extracted and concentrated. Clarification is more applicable.

Blood separation, ink separation, Natural pigment separation, Chemical separation, medicine separation, Escherichia coli separation, Biological vaccine separation, Microalgae separation

Product working principle:

On the top of drum is the flinch axis, under is the damp drift bearing. Main axis linked by buffer and passive wheel,via conveyor belt, fasten wheel, the dynamic is transmit to drum and it will rotate axes to run at rapid speed.

The stuff is ripped into via liquid inlet, under the centrifuge force, the stuff along the wall of drum flow upward.

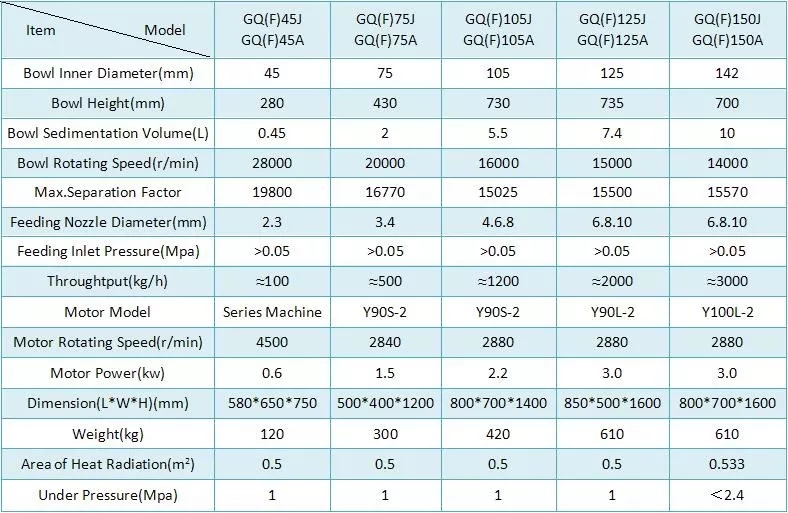

Product Parameters:

Product application case

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1