Decanter centrifuges have become more important for increasingly complex solid-liquid or solid-liquid-liquid separation processes. Sometimes processed industrial or metalliferous minerals are abrasive or are treated with corrosive chemical agents. Traditional mining applications include the processing of coal, gravel and other products, where low-speed decanters, as well as screen bowl decanters and filters, dominate. These have been increasingly replaced by high-speed decanters during the last decade. Decanter centrifuges also started to play a key role in applications such as drilling muds, processing carbonates and separating SX crud in copper platinum ore concentrations of nickel and gold. Communication between machine producers and mineral processing engineers is vital for the right choice of materials and the design of the right decanter centrifuge for the individual process.

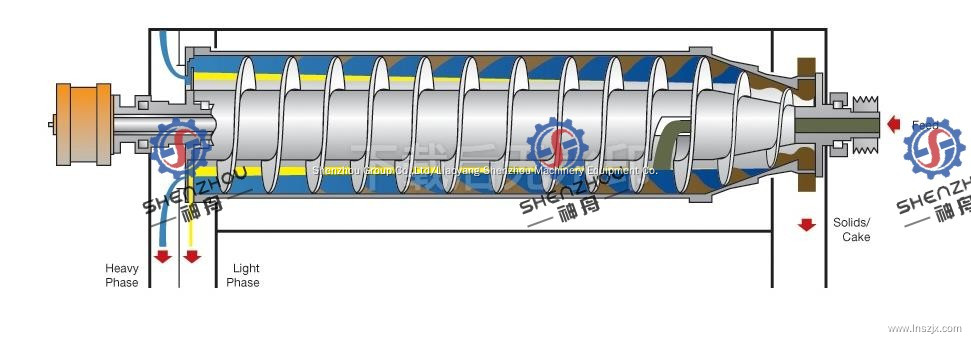

The 2 phase centrifuge offers rapid solid-liquid separation using high-speed and continual rotational processes, making it ideal for industries such as chemical, food, oil, and mining. With a gravitational force well in excess of three-thousand times greater than gravity, this centrifuge reduces the separation process from hours to seconds. Featuring a counter-current type technology, solid particles are compacted and settled out in the inner drum and transported for removal via the solids discharge end, while the centrate is removed from the opposite end.

Team strength is at the heart of our 2 Phase Centrifuge, ensuring rapid solid-liquid separation with maximum efficiency. Our team of experienced engineers and technicians have meticulously designed and tested this innovative device to guarantee seamless operation and reliable results. With a strong emphasis on collaboration and expertise, we have created a product that exceeds industry standards and meets the demands of modern businesses. Trust in the strength of our team to deliver a centrifuge that will revolutionize your solid-liquid separation processes, making your workflow more efficient and productive than ever before.

Our 2 Phase Centrifuge boasts unparalleled team strength, with a robust design and powerful performance that highlights our dedication to rapid solid-liquid separation. Our expert team of engineers has meticulously crafted this innovative product to deliver exceptional efficiency and precision, ensuring seamless operation and consistently high-quality results. From our skilled technicians to our knowledgeable customer support team, our commitment to excellence shines through in every aspect of this centrifuge. With unparalleled team strength backing our product, you can trust that you are investing in the best equipment for your separation needs.

What is a Decanter Centrifuge?

Definition of a Decanter Centrifuge

A decanter centrifuge, also known as a horizontal bowl centrifuge, solid bowl centrifuge or scroll centrifuge, is a machine used to separate a solid material from a liquid(s) using a high-speed and continual rotational process. While wastewater treatment of biosolids is a primary application, the separation of one solid material from one liquid (2-phase dewatering) in a slurry is also important for a number of industries including chemical, food, oil, and mining to name a few.

How A Decanter Centrifuge Works

The separation of a solid and liquid(s) in a decanter centrifuge system work on the principle of gravitational forces. Whereas it takes considerable time for the gravitational separation of a muddy mixture (to fall to the bottom) and water (to rise to the top) in separation technologies based on 1xG separation such as,a static container, clarifier or lamal separator, the rapid rotation of a centrifuge greatly speeds up this gravitational principle.

In fact, the G-force generated by a decanter centrifuge can be well in excess of three-thousand times greater than gravity reducing the separation process from hours to mere seconds. Today's centrifuges are a counter-current type technology. The separation process in a 2-phase decanter centrifuge results in the denser solid particles to be compacted and settled out in the inner drum and then transported and removed via solids discharge end of the decanter. The centrate is routed to the opposite end of the centrifuge and removed via the centrate outlet. In a 3-phase centrifuge, the baffle system is built inside the centrifuge. The baffle system blocks the oil from being discharged with the water. The oil (the lighter phase fluid) is collected between the two baffles and skimmed off the top.

The Sample Analysis and Pilot Testing Advantage

The basic operation includes the following centrifuge parts and how they function:

The feed material enters the centrifuge via the feed pipe inlet on one end of the centrifuge

Due to centrifugal force, the heavier particles are pushed through the liquid and collected on the inner wall of the bowl; the high speed rotation of the bowl separates the solids and liquid materials

The continuous rotation of the bowl can be accomplished by a VFD (Variable Frequency Drive)

The scroll conveyor (scroll) inside the bowl rotates at a slightly different speed than the bowl (differential speed)

The scroll conveyor continuously scrapes the solids off the inner bowl wall and moves the solids in the direction of the centrifuge conical's solids discharge area

The liquid (centrate) moves in the opposite direction from the solids due to Pascal's Law (or a system of combined piping) and because the solids discharge end is sealed by the solids

The differential speed of the centrifuge controls the solids retention time; the longer the solids are under g-force the drier the solids become in the dewatering process

Types of Sludge

Waste Activated Sludge (WAS) / Secondary Sludge – (0.8-1.3% TS)

Has natural separation of free water (floc) and is easily settable

Little to no polymer is required. (*)(**)

* Traditional decanter centrifuges used for sludge thickening can work using little to no polymer but require higher energy consumption or the capacity of the equipment is limited. Other thickening technologies (rotary drum, gravity belt, DAF) need polymer to produce 4-5% solids concentration.

**The Centrisys THK Sludge Thickener will achieve 4-5% solids concentration using no polymer, with 50% less energy consumption and increased capacity compared to traditional decanter centrifuges.

Primary Sludge - (1.5-5% TS)

Solids are heavy and settable but laden with colloidal material (hazy)

Hard to remove fine particles

Polymer is usually required

Digested Sludge – (1.5-3% TS)

Not easily settable;

Polymer is usually required

Transportation costs based on tonnages

Landfill percent of solids concentration requirements

Whether the sludge can be disposed in a sludge lagoon

Sludge thickening using a decanter centrifuge before a digestion treatment process will reduce the size of the digester, and can be used before sludge storage and liquid land applications. Depending on the utilization of the sludge product (landfilled, land applied or dried) the drier the product the more cost effective it will be for storage, transportation and disposal.

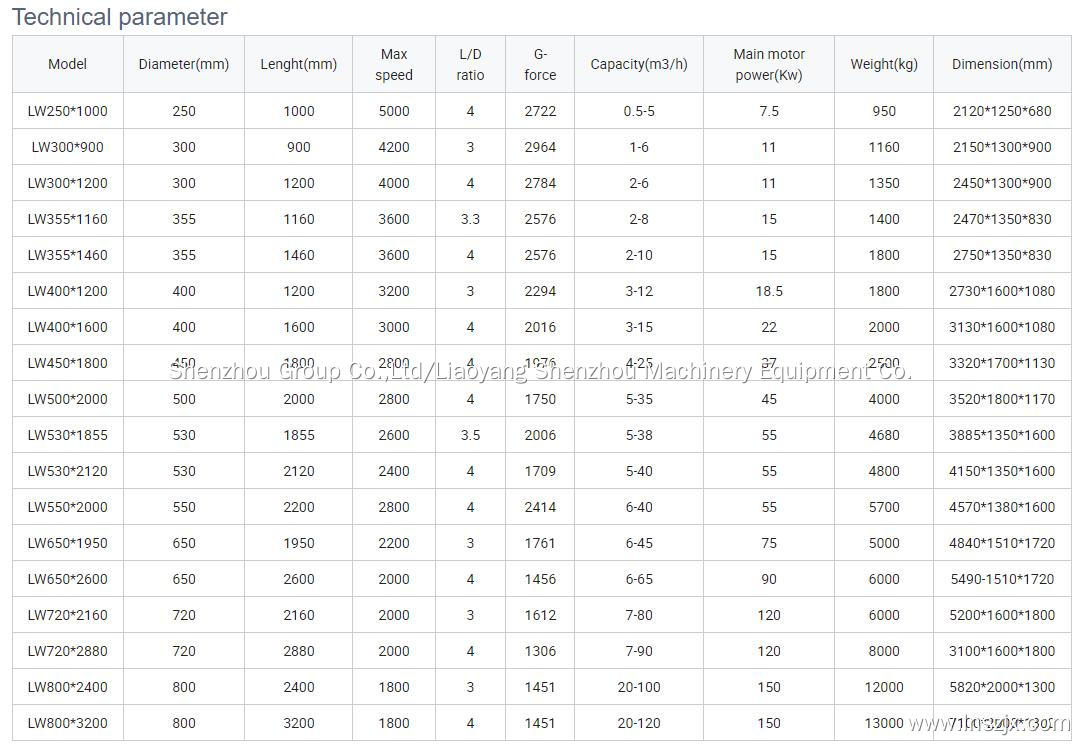

Technical Parameters:

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Decanter Centrifuge and an unforgettable experience of partnering with us.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

In essence, a long-standing 2 phase centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the 2 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The buyers of 2 phase centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1