2 Phase Disc Centrifuge for Beverage Separation

Product advantages

Our 2 Phase Disc Centrifuge for Beverage Separation offers efficient separation of liquids and solids, resulting in higher product quality and reduced production time. With a compact design and easy operation, this centrifuge is perfect for beverage processing plants looking to streamline their production processes. Its innovative features such as adjustable speed settings and automatic cleaning make it a must-have tool for any beverage manufacturer.

Company profile

Company Profile: With a history of excellence in the field of separation technology, our company is a leading provider of 2 Phase Disc Centrifuges for beverage separation. Our advanced equipment is designed to efficiently separate liquids of varying densities, ensuring the highest quality end products. We are dedicated to innovation, quality, and customer satisfaction, with a team of experienced professionals committed to providing top-notch service and support. Trust in our expertise and industry knowledge to meet your beverage separation needs with precision and efficiency. Experience the difference of working with a trusted leader in the industry.

Why choose us

Our company specializes in providing high-quality separation solutions for various industries, including the beverage industry. Our 2 Phase Disc Centrifuge is designed specifically for efficient separation of beverages, ensuring optimal quality and taste. With advanced technology and precise engineering, our centrifuge is reliable and easy to operate, making it a valuable asset for any beverage production process. We are committed to providing top-notch customer service and innovative solutions to meet the unique needs of our clients. Trust us to deliver superior performance and exceptional results with our cutting-edge centrifuge technology.

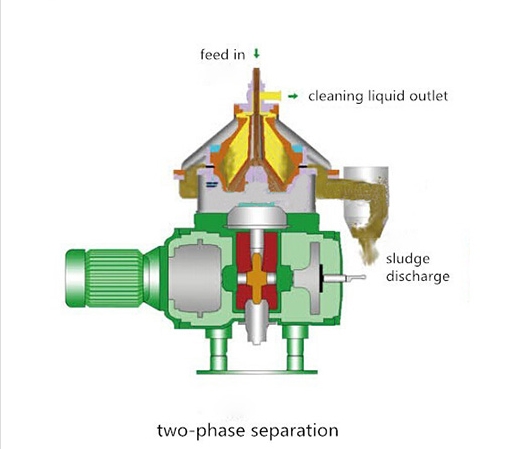

Product Description

Shenzhou group juice disc centrifuge separator speciallu used for Juices, colorings, beverage separator is mainly used for apples, pears, peaches, sea buckthorns, sweet potatoes, fruits and vegetables processing, also used for beer and malt clarification. It can be used for sparkling wine, wine, juice, beverage and other similar materials concentration, clarification and purification. If processing muddy juice, you can select decanter centrifuge, if processing juice, you need to use the disc centrifuge.

Product features:

1. Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise

and vibration, the installation path is very easy to operate.

2. The bearings use imported FAG, transducer using Japan brand “ Fuji”, the main strengthen parts of Roller body and Roller cover use 2Cr13,and the other parts of contacted materials such as Disc all use 304L.

3. The Stainless steel cover use SUS304

4. The base use casting steel, coating does the same way as ship bottom.

Function:

the disc centrifuge separates solids and one or two liquid phases from each other in one single continuous process, using extremely high

centrifugal forces. When the denser solids are subjected to such forces, they are forced outwards against the rotating bowl wall, while the less

dense liquid phases form concentric inner layers. The area where these two different liquid phases meet is called the interface position.

This can be easily varied in order to ensure that the separation takes place with maximum efficiency. Inserting special plates (the “disc stack”)

provides additional surface settling area, which contributes to speeding up the separation process dramatically. It is the particular configuration,

shape and design of these plates that make it possible for a disc stack centrifuge to undertake the continuous separation of a wide range of

different solids from either one or two liquids. The concentrated solids phase formed by the particles can be removed continuously,

intermittently or manually, depending on centrifuge type and the amount of solids involved in the specific application.

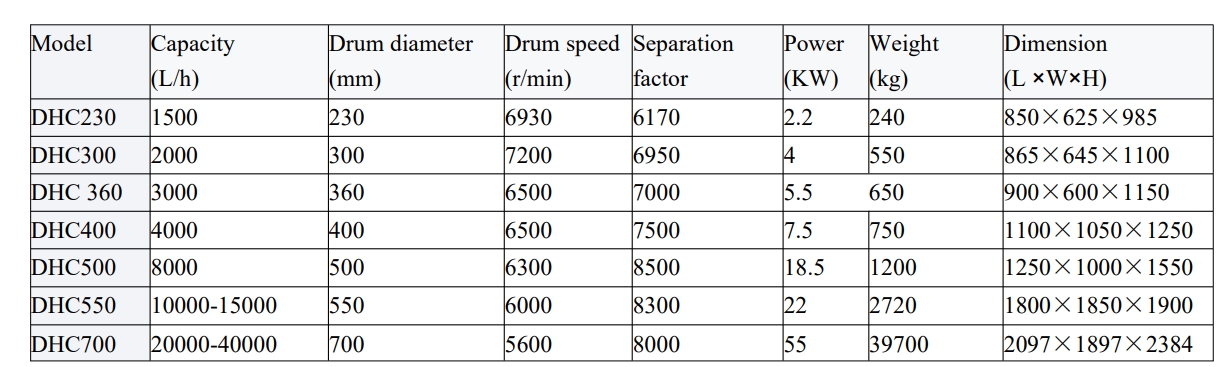

Technical Parameter

customers from other countries visited Shenzhou Group