3 Phase Centrifuge for Efficient Oil Separation1

Product advantages

Our 3 Phase Centrifuge offers efficient oil separation through its advanced technology and robust design. With a high-speed spinning action, it quickly separates oil, water, and solids, increasing productivity in various industries. Its compact size and easy operation make it a versatile and convenient solution for oil separation needs.

Team strength

At our company, we believe that our team strength sets us apart in delivering the most efficient 3 Phase Centrifuge for oil separation. With a diverse group of experts in engineering, technology, and operations, we have the knowledge and experience to develop cutting-edge solutions for our customers. Our team's dedication to quality and innovation ensures that our centrifuge not only separates oil efficiently but also performs reliably in all conditions. By leveraging our collective expertise and collaborative approach, we are able to provide the best possible solution for oil separation needs. Choose our centrifuge and experience the power of our team strength.

Why choose us

At the core of our 3 Phase Centrifuge for Efficient Oil Separation is a team of dedicated engineers, designers, and technicians who have worked tirelessly to develop a machine that exceeds industry standards. Our team's expertise in centrifugal technology, oil separation processes, and mechanical engineering ensures that our centrifuge is not only efficient and reliable but also ahead of the competition. By combining our collective knowledge and skills, we have created a product that delivers exceptional results, saves time and money, and ultimately helps our customers achieve their oil separation goals with ease. Choose our centrifuge and experience the strength of our team first-hand.

Bowl Type Industrial Oil Separator Machine For Vegetable Oil Refining is a hot seller well recognized by users around the world. We pride ourselves on our personalized and efficient service. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd will continue to gather more industry elites and improve our technology to upgrade ourselves. We hope to achieve the goal of realizing independent production without relying on others' technologies.

Product Description

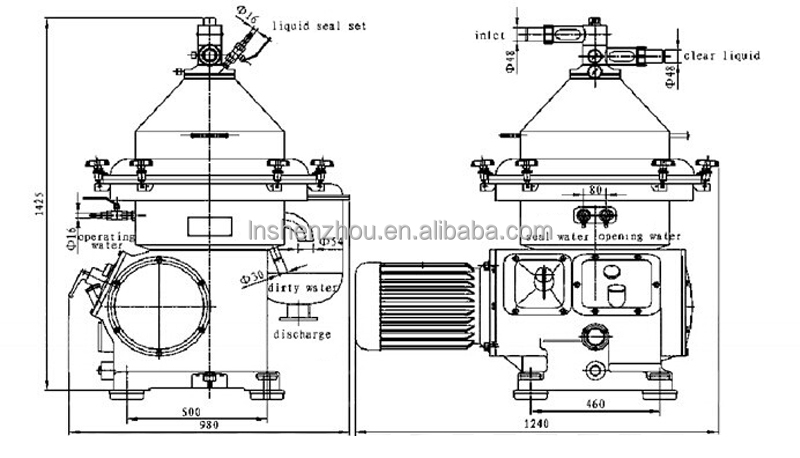

Model | Treatment capacity (L/H) | Inlet Pressure (Mpa) | Outlet pressure (Mpa) | Motor power (Kw) | Weight (Kg) | Outline dimension (mm) |

DHN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1530*1150*1500 |

DHN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1750 |

DHN550 | 10000-20000 | 0.05 | 0.1-0.4 | 22 | 2300 | 1950*1550*1960 |

DHN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3000 | 2185*1728*2082 |

Model | DHNZ360 |

Treatment capacity (L/H) | 2000-5000 |

Inlet Pressure (Mpa) | 0.05 |

Outlet pressure (Mpa) | 0.1-0.35 |

Motor power (Kw) | 7.5 |

Weight (Kg) | 1200 |

Outline dimension (mm) | 1530*1150*1500 |

* 1Warm milk separation

* 2 Cold milk separation

* 3 Whey separation

* 4 Buttermilk separation

* 5 Milk and whey clarification

* 6 Milk standardisation

Bowl Type Industrial Oil Separator Machine For Vegetable Oil Refining

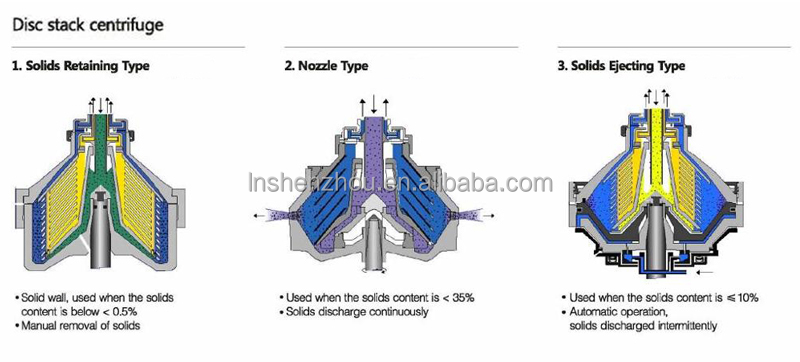

Besides, some nozzles is mounted around the drum to spray slurry sediment, whose number and aperture are determined on the properties of the suspension, the degree of concentration and the amount of treatment.

In order to improve the slag concentration, recovery device is configured with this disc separator to the discharged sediment for reuse. For the solid concentration of the slag can be increased by 5~20 times than that of the feeding materials.

The processing capacity of the separator is up to 30t/h, which is suitable for suspension with solid phrase in diameter of 0.1~100 microns and concentration less than 10% (maximum to 25%).

We are based in Liaoning, China, start from 1980 sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian