Our 3-Phase Disc Centrifuge with PLC Control is manufactured using high-quality stainless steel, ensuring durability and longevity. With its advanced PLC control system, this oil separator provides precise and efficient separation of oil, water, and solids. The cost-effective design of this centrifuge makes it a practical and reliable solution for a wide range of industrial applications.

With over 20 years of experience in manufacturing high-quality industrial equipment, our company prides itself on providing top-of-the-line solutions for separating oil from water in various industries. Our 3-Phase Disc Centrifuge with PLC Control is built with durable stainless steel materials, ensuring longevity and efficiency. Designed to meet the highest standards, our product offers cost-effective solutions without compromising on quality. With our commitment to innovation and customer satisfaction, we strive to deliver reliable and high-performance equipment that exceeds expectations. Trust in our expertise and experience to supply you with the best oil separator on the market.

Company Profile:

As a leading provider of industrial separation solutions, our company specializes in manufacturing high-quality and cost-effective equipment such as the 3-Phase Disc Centrifuge with PLC Control. With a strong focus on innovation and customer satisfaction, we ensure that our products are made from premium stainless steel for durability and efficiency. Our expertise in producing oil separators has earned us a reputation for delivering consistent and reliable performance in various industries. By combining cutting-edge technology with expert craftsmanship, we are committed to providing top-of-the-line solutions that meet the needs of our clients while exceeding industry standards.

Product Introduction

Disc separator is a 3-phase vertical centrifuge, mainly used for coconut water purifying. It is also used for similar materials for the Liquid-Liquid-Solid three-phase separation, such as milk, etc.

The machine is one kind of rotary machine with high speed. After accurate dynamic balancing, it can run for a long time with low vibration, safety, and security.

Application of shenzhou disc separator

Animal and vegetable oil separation

Beverage industry

Pharmaceutical industry

Plant extraction and separation

Chemical industry separation

Fuel and marine oil industry

Environmental protection industry

Working Principle Of disc stack centrifuge

Disc Stack Centrifuge is also called Disc Centrifuge or Disc Separator or Conical Plate Centrifuge, which can be used to separate solid and liquid under high-speed centrifugal force.

Disc Stack Centrifuge is Vertical centrifuge, it is driven by one motor that rotates at high speed. Inside the rotating bowl of the disc Centrifuge is a set of disc-shaped parts nested with each other-commonly known as discs. A small gap among the discs, which are used for centrifugal sedimentation of materials.

Suspension liquid (or emulsion) is feed by gravity usually or a feeding pump into the bowl of the disc Centrifuge. When the suspension liquid (or emulsion) flows through the gap between the discs, solids (or droplets) are settled on the disc and become sediment (or liquid layer), the sludge slides along the surface plate of the disc to separate from the disc and accumulates in the inner bowl where the diameter is large, and the separated liquid is discharged from the bowl through the liquid outlet.

For the 3-phase disc Centrifuge, there are two centripetal pumps inside, which can discharge the two immiscible liquid phases having difference densities. The function of the discs in the disc Centrifuge is to shorten the settling distance of solid particles (or droplets) and enlarge the effective settling area of the bowl in order to greatly improve the production efficiency. The solids accumulated in the bowl can be discharged through the automatic slag discharge mechanism without disc centrifuge stopping. Solid-liquid-liquid 3-phase separation or solid-liquid separation can be achieved by using Disc Stack Centrifuge.

All contacting parts of the Disc Stack Centrifuge is made of high-grade stainless steel, which effectively reduces the chemical interaction between the separated material and the surface of the contacting part. The separated light and heavy phase liquid materials are output by two centripetal pumps of different sizes. This machine adopts upper feeding, which has lower inlet pressure on the material. Hydrodynamic coupling and a pair of helical gears or belt drive are used in the power transmission. The speed increase is stable and overload protection can be performed.

The slag discharge action of the sliding piston is automatically controlled by a PLC fully automatic control cabinet specially designed with safety protection devices. It is high level automation, strong adaptability for process adjustment, and convenient adjustment, low noise and good separation effect.

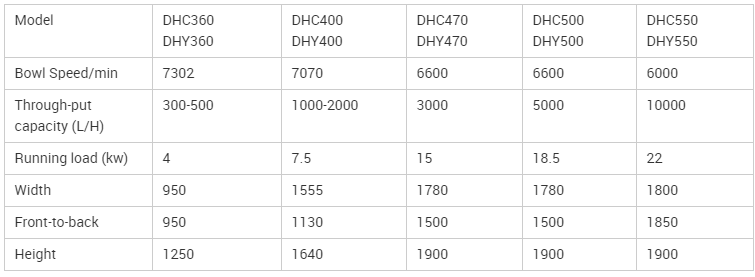

Tehcnical Parameter of disc stack centrifuge from Shenzhou

guarantee of Shenzhou disc separator

1. 12 months guarantee period from machine arrival date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4. 7*24 hours technical consultation.

5. Your workers could get trained both in our factory and yours.

6. Routine tracing till the machine work properly will be done timely.

7. We will remind you to do normal maintenance.

8. Your suggestions or any comments & reflection would be treated as a priority.

9. Marketing team will visit you during our visit to your country if you require.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1