3 Phase Tubular Centrifuge - High-Tech Fish Oil Separator

Product advantages

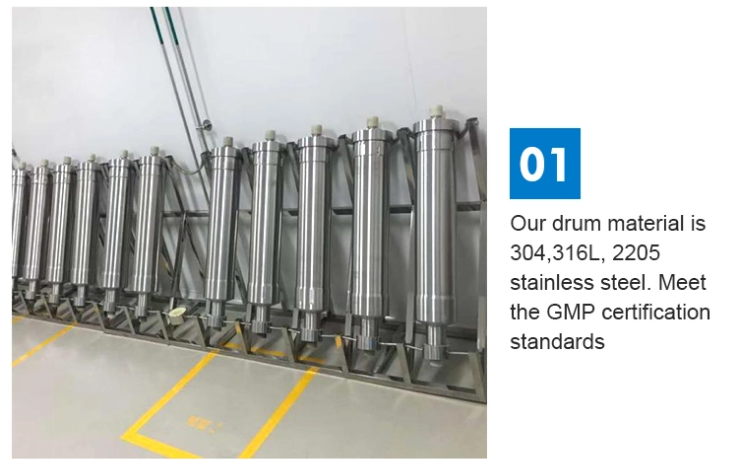

The 3 Phase Tubular Centrifuge - High-Tech Fish Oil Separator offers advanced separation technology, allowing for efficient extraction of fish oil with minimal waste. Its compact design and robust construction make it a reliable and long-lasting solution for fish oil production processes. With high-speed rotation and precise control mechanisms, this centrifuge ensures high purity and quality of the extracted fish oil.

We serve

At our company, we serve customers in need of high-quality separation equipment with our cutting-edge 3 Phase Tubular Centrifuge. This high-tech fish oil separator is designed to efficiently separate liquids of different densities, making it ideal for the pharmaceutical, food, and chemical industries. With a focus on precision and reliability, our centrifuge ensures maximum productivity and product quality. We strive to ensure customer satisfaction by providing superior technical support and personalized service. Trust us to serve your needs with top-of-the-line technology and expertise in centrifugal separation. Experience the difference with our 3 Phase Tubular Centrifuge today.

Enterprise core strength

At our company, we serve our customers with cutting-edge technology in the form of our 3 Phase Tubular Centrifuge - High-Tech Fish Oil Separator. This innovative machine is designed to efficiently separate fish oil from other liquids, providing a high-quality end product for our customers. We pride ourselves on our commitment to serving the needs of our clients by offering reliable and high-performance equipment. With our expertise in e-commerce product operations, we ensure a seamless purchasing experience for our customers. Trust us to serve you with top-of-the-line equipment that delivers exceptional results every time.

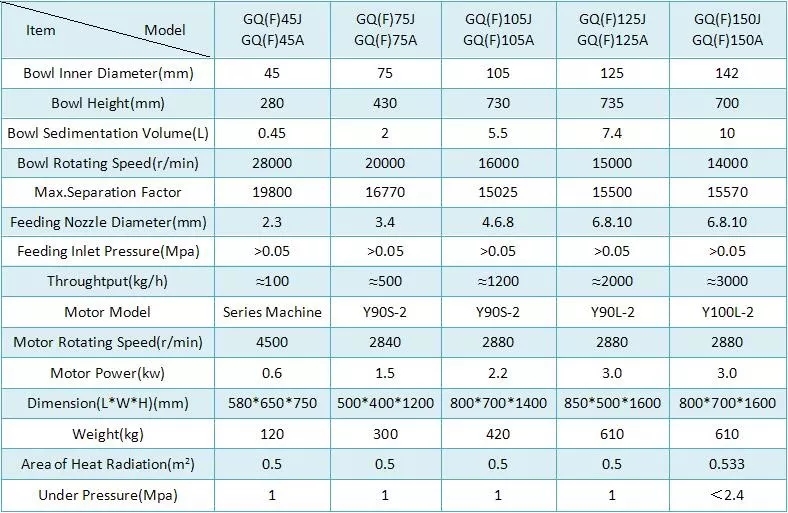

Product Description

GF SERIES: used for separating various emulsions, especially for liquid- liquid separation with a small proportion of two-phase and liquid-liquid- solid separation with a small amount of impurities, such as transformer oil, turbine oil,lubricating oil, fuel oil, dye, grease, saponification, all kinds of powder materials, all kinds of oral liquid, all kinds of pharmaceutical liquid, 920

separation; Separation of plasma biological drugs and extraction of plasma from animal blood; Edible oil, CAI pan soak liquid, tea Phenol, soybean concentrated phospholipid refining, oil and water separation and sewagetreatment.

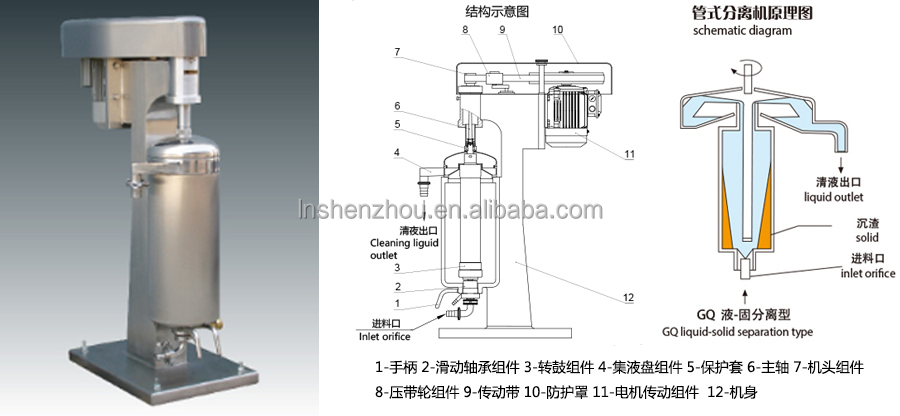

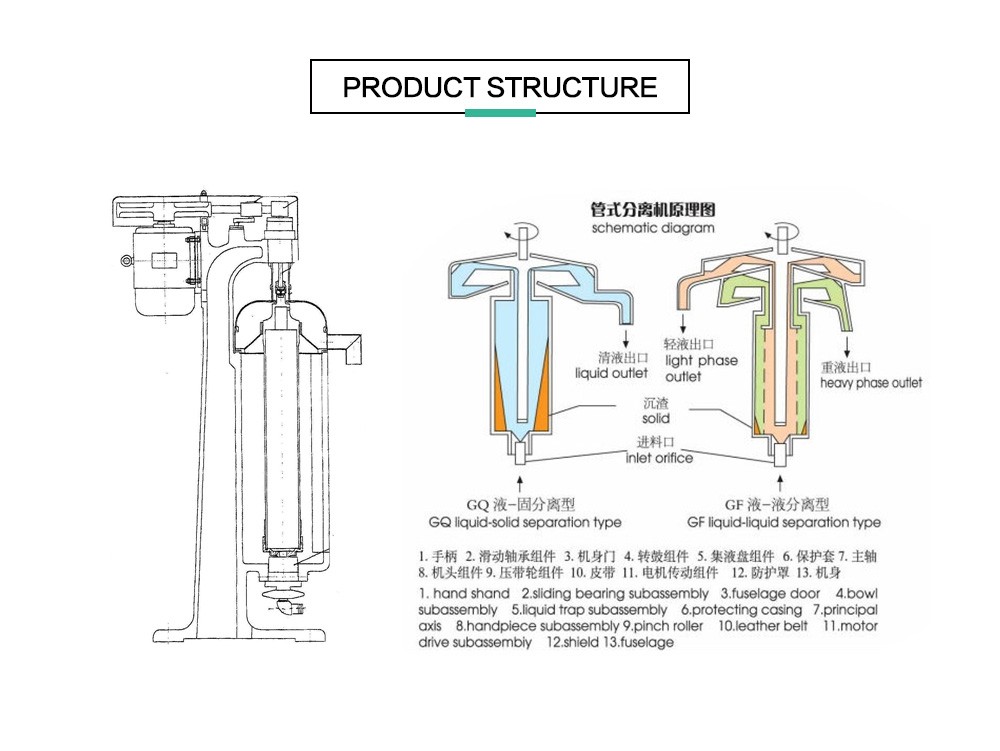

Consist of the machine cover, driving device, drum, liquid catch tray, the liquid inlet and bearing seat, this separator with high running speed, belongs to sedimentation separator. The upper drum is a flexible shaft, while the lower is damping floating bearing. The main shaft is connected by a coupling buffer and a passive wheel. Motor transmit power from the transmission belt and tension wheel to passive wheel, to drive the drum rotate around its own axis with high-speed, and thus form a strong centrifugal force field. All the materials are fed from liquid inlet under the bottom, and flow upward along the drum wall by centrifugal force fluid. During this process, the dense liquid phase forms the outer ring, and the small liquid phase forms the inner ring, which separately flow to respective liquid outlet mounted on the upper drum.

When the thickness of the sediment affect the liquid phase clarification or the capacity of the rated slag weight in the drum, the dregs of the drum wall should be removed manually after the shutdown.

GF-for separation:

GQ-for clarification:

1. Provide 24-hour technical consulting reply;

2. Provide professional quoted price;

3. Provide detailed product performance specification;

4. According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper

product types;

5. Provide other corollary equipment according to client requirements.

In-sale Service

1. Begin to supervise from raw material, its qualified rate can reach to 100%;

2. Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach to 100%;

3. Provide product’s inspection record of key junctures to customers;

4. Provide production schedule photos to customers at regular intervals;

5. Package and transport products strictly accordance with export standard;

6. Provide transportation schedule information to clients timely.

1. Provide targeted installation video;

2. Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

3. When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

4. During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

5. If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour

and provide solution or send staff to spot within 24 hours after receiving maintenance notification.

6. Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

7. Provide assistant service if product is damaged during transportation.

FAQ

We can provide CE, ISO 9001, etc

2. What is the warranty period of the equipment?

Normally 1 year warranty.

3. Can we visit your factory?

Of course, we sincerely invite you to visit, If it's not convenient for you to come to our factory, you can also visit by

telephone video conference.

4. What's payment you accept?

A4: T/T, Western Union, L/C, Ali Pay, etc

5. Can it be customized?

Of course, our equipment can be customized according to the actual requirements of customers.