The Cost-Effective 3 Phase Tubular Centrifuge is a high-speed separation equipment suitable for suspensions with thin concentration, fine particles, and small density differences for solid-liquid or liquid-liquid-solid separation. With a square or round enclosure shape, stainless steel 304 and 316L construction, and a door-opening design for easy disassembly, this centrifuge offers convenience and durability. Optional VFD control cabinet with PLC and touch screen, explosion-proof and cooling options, and a mobile integrated base provide versatility and enhanced functionality for various industrial applications.

Our company, a leading manufacturer in the industrial machinery sector, is proud to present our cost-effective 3 Phase Tubular Centrifuge. With years of experience and expertise in the industry, we are committed to delivering high-quality products that meet the needs of our customers. Our centrifuge is designed to provide efficient separation of liquids, making it ideal for a wide range of applications. Built with durability and reliability in mind, our centrifuge offers exceptional performance at an affordable price point. Trust in our company for all your centrifuge needs and experience the difference in quality and value.

Company Profile:

Our company is a leading provider of cost-effective industrial equipment, including our innovative 3 Phase Tubular Centrifuge. With a focus on superior quality and cutting-edge technology, we strive to meet the needs of our customers by providing reliable and efficient solutions. Our team of dedicated experts ensures that each product we offer meets the highest standards of performance and durability. By choosing our company, you can trust that you are investing in a product that will deliver excellent results and help streamline your operations. Experience the difference with our cost-effective 3 Phase Tubular Centrifuge.

Product Description of tubular bowl separator from Shenzhou

High Speed Tubular Centrifuge, also called Tubular Bowl Separator, is a kind of fine separation equipment suitable for suspensions with thin concentration, fine particles, and small density difference solid-liquid separation, or liquid-liquid-solid separation. It is indispensable equipment for pharmaceutical, food, chemical, biological product, fermentation broth, beverages, blood products and other industries. High Speed Tubular Centrifuge working principle is that materials with different specific gravity are subject to different centrifugal forces when rotating at high speed, so as to achieve the purpose of separation.

Product Description of GF Tubular centrifuge

GF Separation Tubular Centrifuge

(Light liquid-heavy liquid-solid phase)

The GF type is mainly used for various difficult-to-separate suspensions in the separation industry, and is especially suitable for liquid-liquid separation with small specific gravity differences and liquid-liquid-solid three-phase separation with a small amount of impurities.

GF Working Principle

1.The centrifuge rotates at a high speed to reach a suitable working speed (the speed can be adjusted control panel), and the mixed suspension is continuously fed from the bottom, and the suspension are layered under the action of centrifugal force;

2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet;

3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, need to re-install the rotor, and then start the next separation process

Product features of high speed tubular centrifuge

The enclosure shape is of square shape and round shape.

Stainless steel 304 is used for the surface wrapping of the enclosure.

Stainless steel 316L for the parts in contact with the suspension.

The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

According to the field of use, explosion-proof type and cooling type with cooling coil are available.

Mobile integrated base is available.

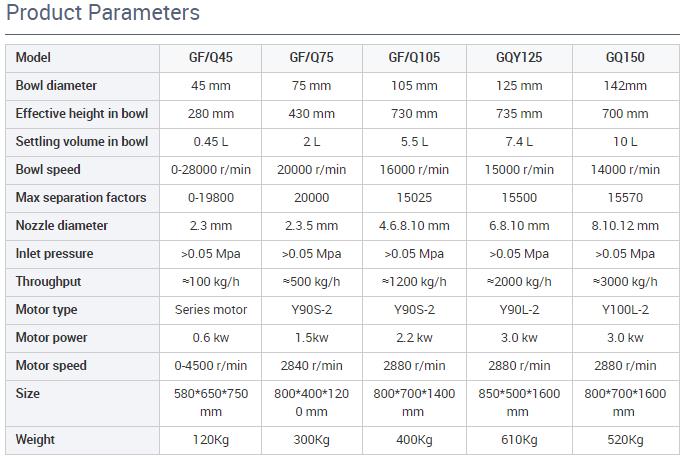

Technical Parameter

Our Customers

Regarding the attributes and functionality of the 3 Phase Tubular Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 3 Phase Tubular Centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 3 Phase Tubular Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing 3 Phase Tubular Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

In China, ordinary working time is 40 hours for employees who work full time. In Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality GK & GKH centrifuge and an unforgettable experience of partnering with us.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1