Efficient 2 Phase Tubular Centrifuge for Juice Clarification

Product advantages

Our Efficient 2 Phase Tubular Centrifuge for Juice Clarification utilizes innovative technology to quickly and effectively separate juice from pulp, resulting in a clearer and more refined product. Its high-speed operation ensures maximum efficiency, saving time and energy in juice production processes. With easy-to-use controls and durable construction, this centrifuge is a reliable and essential tool for any juice processing facility.

Company profile

With a rich history of innovation and expertise in centrifuge technology, our company is a leading provider of efficient 2 phase tubular centrifuges for juice clarification. Our state-of-the-art equipment is designed to provide maximum efficiency and clarity in the juice clarification process, helping to ensure a higher quality end product for our customers. We are dedicated to providing reliable and effective solutions for our clients in the food and beverage industry, helping them to streamline their operations and achieve their production goals. Trust our company for top-notch equipment and superior customer service.

Why choose us

With a strong emphasis on innovation and efficiency, our company specializes in providing high-quality 2 phase tubular centrifuges for juice clarification. Our cutting-edge technology ensures maximum productivity and minimal waste, resulting in cost savings for our customers. We prioritize customer satisfaction and strive to exceed expectations with our superior products and unparalleled customer service. Our dedicated team of experts is committed to delivering top-of-the-line solutions that meet the unique needs of our clients. Trust in our company for all your juice clarification needs, and experience the difference of working with a reputable industry leader.

With the effort of excellent designers,centrifugal clarifier for juices has unique style in its shape and appearance. We have been constantly developing new technologies to manufacture value-added centrifugal clarifier for juices.It can be widely found in the application field(s) of Separation Equipment. In the future,centrifugal clarifier for juices will increase more capital and technology investment to continuously improve the comprehensive competitiveness of the enterprise, and strive to remain invincible in the market forever.

| Place of Origin: | Liaoning, China | Type: | Centrifuge |

| Product Type: | Soap | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Hot Product 2021 | Warranty of core components: | 2 years |

| Core Components: | Bearing | Brand Name: | LYSZ |

| Voltage: | Customized | Weight: | 220 |

| Dimension(L*W*H): | 580*650*750 mm | Warranty: | 2 years |

| Key Selling Points: | High Productivity | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location: | None |

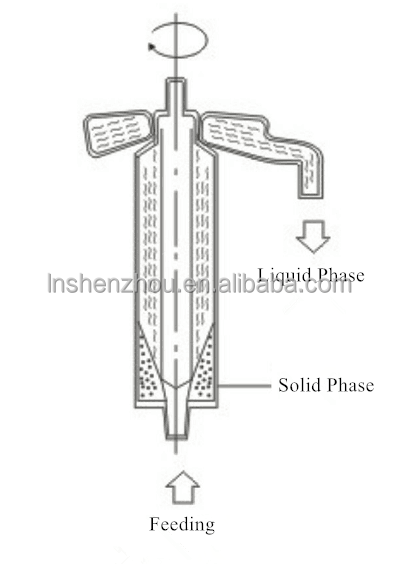

SZGQ Clarification Tubular Centrifuge

(Liquid phase-solid phase)

2. The density of the liquid in the suspension is relatively small, and it spirally rises gradually from bottom to top and then continuously discharges from the clear liquid outlet on the upper part of the rotor;

3.The solid phase is relatively heavier, and it will settle inside the bowl. After the solid is collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, you need to reset the rotor installation, and then start the next separation process.

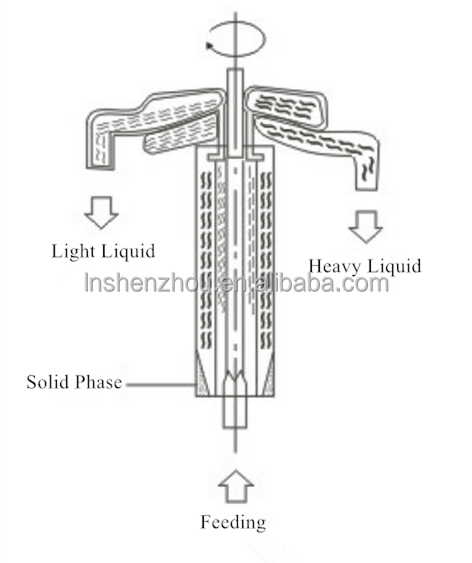

SZ GF Separation Tubular Centrifuge

(Light liquid-heavy liquid-solid phase)

2.The two liquids in the suspension have a difference in density and are incompatible with each other. The liquid phase spirally rises gradually from bottom to top to the upper part of the rotor. The liquid phase with a smaller density is discharged from the light liquid outlet, and the liquid phase with a larger density is discharged from the heavy liquid outlet;

3.The solid phase density is the largest, and it will settle inside the bowl. After the solids are collected, turn off the centrifuge, and manually remove the rotor for slag cleaning;

4. After cleaning the slag, need to re-install the rotor, and then start the next separation process.

Model | GF/GQ75 | GF/GQ105 | GQ/GF125 | GQ/GQ150 | |||

Diameter(mm) | 75 | 105 | 125 | 147 | |||

Height (mm) | 450 | 730 | 730 | 730 | |||

Sedimentation volume(L) | 2.67 | 6 | 8 | 10 | |||

Max speed(r/min) | 20000 | 16800 | 15800 | 14500 | |||

Max separation factor | 21000 | 15300 | 16300 | 15600 | |||

Inlet nozzle diameter (mm) | 3/4 | 4/6/8 | 4/6/8 | 4/6/8/10 | |||

Material inlet pressure (Mpa) | ≥0.05 | ||||||

Capacity (Water capacity)L | 670 | 1600 | 2200 | 3200 | |||

Motor model | 3 phase two pole motor | 3 phase two pole motor | 3 phase two pole motor | ||||

Motor power (kw) | 1.5 | 2.2 | 3 | 3 | |||

Machine dimension (mm) | 500*700*1300 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | |||

Machine weight (kg) | 260 | 490 | 510 | 550 | |||

* Stainless steel 304 is used for the surface wrapping of the enclosure.

* Stainless steel 316L for the parts in contact with the suspension.

* The enclosure body with door-opening design is convenient for disassembly and assembly of the bowl, reduces labor intensity and the separation effect is not affected.

* Optional VFD control cabinet, start by inverter, adjustable speed, reduce the starting current and the degree of damage to the transmission components and wear parts, and improve the service life of the equipment and the motor.

* The control cabinet is optionally equipped with PLC and touch screen to display the speed and temperature.

* According to the field of use, explosion-proof type and cooling type with cooling coil are available.

* Mobile integrated base is available.

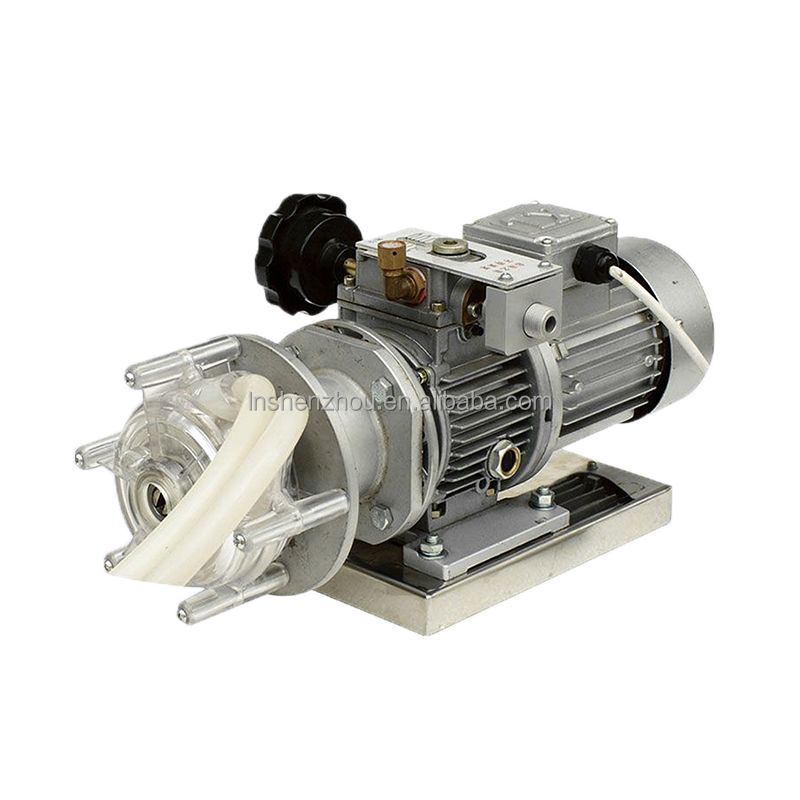

Model | SZRB-10 |

Speed (RPM) | 200-700 |

Flow (L/min) | 4-10 |

Pressure (kg) | 1.5 |

Motor Power (w) | 220 |

Hose inner/outer Dia. (mm) | Φ10x16.5 |

Weight (kg) | 12 |

Dimension (mm) | 460x200x210 |

The material of the hose is strictly selected and made of non-toxic silicone rubber or polychloroene material, which meets the hygienic standards in biochemical and medical fields. This kind of pump is with novel design, simple structure, step-less speed change to adjust the flow, suitable for working in humid environment, easy to operate, and easy to clean and disinfect.

Peristaltic pump is widely used in hospitals, biochemistry and other industries to pump blood and other liquids. It can also be used for transporting liquids in other industries. It is suitable to be used as a feed pump for high-speed tubular centrifuges.

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian