Product advantages

Our High-Speed 3 Phase Centrifuge offers automatic slag discharge and separation, making it incredibly efficient and user-friendly. With a powerful three-phase motor, this centrifuge can quickly separate substances of different densities for a wide range of applications. Its advanced features provide optimal performance and excellent results, making it a must-have for anyone in need of high-speed centrifugation.

Team strength

At our company, our team's strength lies in our expertise in designing high-speed 3 phase centrifuges with automatic slag discharge and separation capabilities. With years of experience in the industry, our engineers and technicians work closely together to ensure the efficiency and reliability of our products. Our dedication to innovation and constant improvement drives us to deliver top-of-the-line equipment that meets the needs of our customers. By focusing on teamwork and collaboration, we are able to provide cutting-edge solutions that set us apart from our competitors. Trust in our team to deliver exceptional performance and quality with every centrifuge we produce.

Enterprise core strength

At High-Speed 3 Phase Centrifuge, our team strength lies in our unwavering dedication to innovation and efficiency. With automatic slag discharge and separation capabilities, our centrifuge ensures optimal performance and productivity in industrial processes. Our skilled engineers and technicians work collaboratively to design and produce top-of-the-line equipment that exceeds industry standards. With a strong emphasis on quality, reliability, and customer satisfaction, our team is committed to providing superior solutions for all your centrifugation needs. Trust in our expertise and experience to elevate your operations to new heights of success.

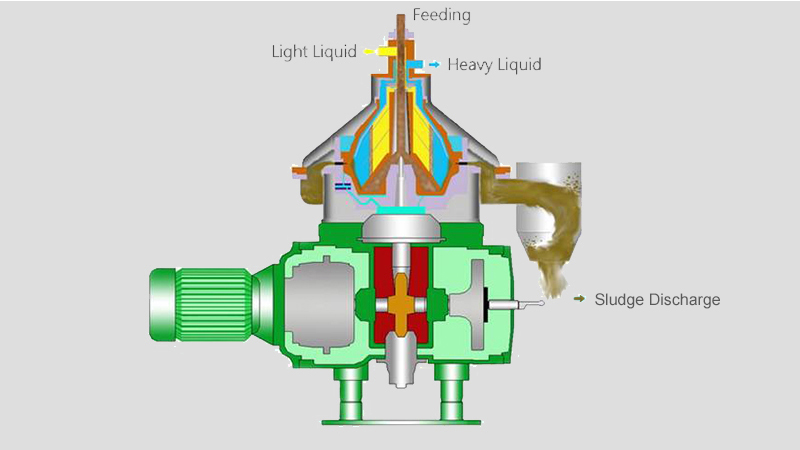

3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation. The 2-phase solid-liquid separation disc separator has only one liquid discharge port and one slag discharge port, while the 3-phase disc separator has two liquid discharge ports and one slag discharge port, which can separate two liquids with different specific gravity at the same time. It can also discharge solid phase materials. Compared with the 3 phase decanter centrifuge, the 3 phase disc separator has larger rotation speed and G force. The 3 phase decanter centrifuge usually has a separation factor of about 3000G, while the 3 phase disc stack separator G force is up to 12000G. Therefore, the 3 phase disc separator can more thoroughly separate liquids with different specific gravity and the liquid phase discharged is more clarified. However, compared to 3 phase decanter centrifuges, 3 phase disc separator is more used to separate materials containing fine particles, with less solids content. So before entering the 3 phase disc separator, the material can separated by the decanter centrifuge for pre-stage separation to reduce the solids content and remove big particles.

Product Introduction

3 PHASE DISC STACK SEPARATOR WORKING PRINCIPLE

The separated material enters into the heart of the machine, that is, the inside of the bowl. Under the action of strong centrifugal force, the material passes through a set of disc bundle separation intervals. With the neutral holes of the disc as the interface, the liquid with larger specific gravity moves along the disc wall towards the outside the neutral hole, where heavy slag accumulates in the sediment area, and the heavy phase liquid flows upward to the centripetal pump; the lighter liquid with a smaller specific gravity moves along the disc wall into the neutral hole and converges to the lower centrifugal pump. The light and heavy liquid phases are discharged by the lower centrifugal pump and the upper centripetal pump respectively; the heavy slag is regularly discharged; continuous production is implemented.

Company Advantages

Its thermal resistance meets the American ASTM standard.

We have always followed the standardization rules for a rigorous production process, saving time and cost for both parties and bringing maximum benefits to you.

Its size accuracy conforms to GB/T14846-1993.

Frequently Asked Questions about separator suppliers

Q:What's payment you accept?

A:T/T, Western Union, L/C, Ali Pay, etc

Q:Do you have technicians for installation?

A:We are responsible for the installation in your country, you can also arrange your staffs to our factory to learn how to operate the machines, after purchased ,we offer English manual book and operation videos.

Q:Where is your factory? How can I visit there?

A:We have two factories,one is in Zhejiang ,one is in Liaoning ,So you can fly to Shanghai airport or Shenyang Air port.

Q:Can you offer oversea service?

A:Yes, if request. But we suggest online problem solving at first. If the problem still shows we can arrange an engineer to go to your factory personally to solve the issue.

Q:What's your advantages compared to your competitors?

A:Quality and experience, as evidenced by 40 patents and over 35 years of experience.