3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation.

Our high-speed 3 phase centrifuge offers efficient separation of liquid, liquid, and solid materials, providing optimal performance in industrial settings. Its advanced design and technology ensure maximum separation efficiency, saving time and resources. With its high rotor speed and precise control system, this centrifuge delivers superior results for a wide range of applications.

Our company is a leading manufacturer of high-speed 3 phase centrifuges, designed for efficient separation of liquid, liquid, solid mixtures. With a focus on innovation and quality, we strive to provide top-of-the-line equipment that meets the needs of various industries such as food processing, pharmaceuticals, and chemical manufacturing. Our centrifuges are known for their reliability, durability, and superior performance, making them a valuable asset for businesses looking to optimize their production processes. Trust in our expertise and commitment to excellence for all your liquid-solid separation needs.

Our company is a leading manufacturer of high-speed 3 phase centrifuges, specializing in efficient liquid-liquid-solid separation solutions for a wide range of industries. With a focus on quality, reliability, and innovation, we are dedicated to providing our customers with top-of-the-line equipment that maximizes productivity and ensures superior results. Our team of experts is committed to delivering cutting-edge technology and exceptional customer service, making us the preferred choice for businesses worldwide. Trust in our company for all your centrifuge needs and experience the difference that our expertise and dedication can make in your operations.

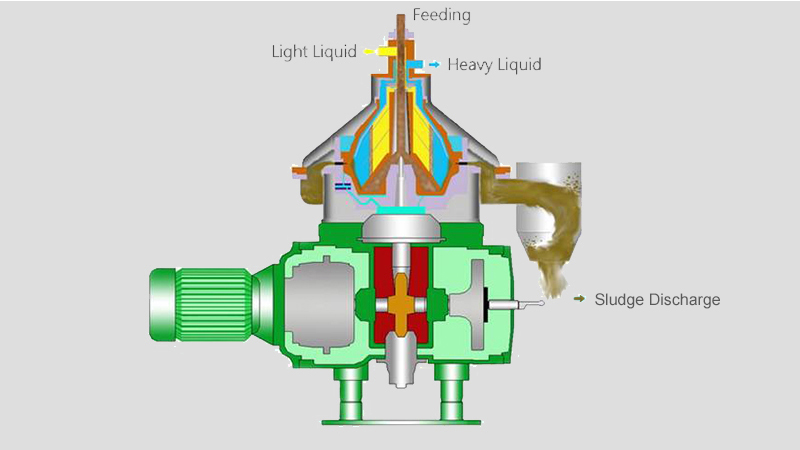

3 PHASE DISC STACK SEPARATOR WORKING PRINCIPLE

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 3 phase centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 3 phase centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The buyers of 3 phase centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1