3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation.

The high-speed 3 phase disc centrifuge separator is a stable, efficient, and automatic slag discharge equipment. With two liquid discharge ports and one slag discharge port, this disc centrifuge can separate two liquids with different specific gravity simultaneously, as well as discharge solid phase materials. Compared to decanter centrifuges, the 3 phase disc separator has a larger rotation speed and G force, allowing for more thorough separation of liquids with different specific gravity and more clarified liquid phase discharge.

In the world of industrial machinery, our High-Speed 3 Phase Disc Centrifuge Separator stands out for its unparalleled team strength. With a powerful trio of separation discs, this centrifuge offers unmatched efficiency and reliability in separating liquids and solids. The robust design and engineering expertise behind this product ensure seamless operation and maximum productivity for your business. Our dedicated team of experts is committed to delivering top-notch performance and support, making us a trusted partner for your separation needs. Invest in our High-Speed 3 Phase Disc Centrifuge Separator and experience the strength of our team in action.

Team strength is at the core of the design and functionality of the High-Speed 3 Phase Disc Centrifuge Separator. Our team of experts in engineering, manufacturing, and customer support have come together to create a state-of-the-art product that delivers exceptional performance and reliability. With years of experience and a shared passion for innovation, our team ensures that every aspect of the separator is built to the highest standards. From the precision-engineered disc stack to the user-friendly control interface, each detail reflects our commitment to quality and customer satisfaction. Trust in our team's expertise to provide you with a high-speed separator that exceeds your expectations.

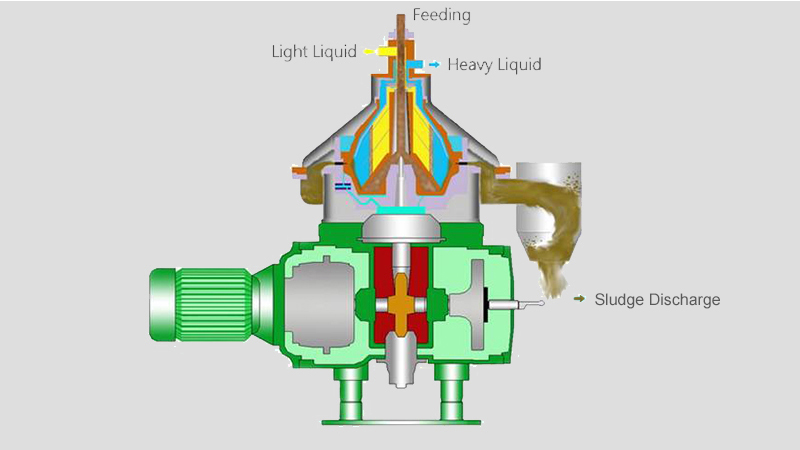

3 PHASE DISC STACK SEPARATOR WORKING PRINCIPLE

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the disc centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing disc centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. disc centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1