Product Description

This type centrifuge is to be added such function as to remove the residual solid cake by pulling filter cloth with the removal rate higher than 99%, highly automated, has large capacity and can be remote-controlled.It is mainly used in the solid-liquid separation process of crystallized materials in such industries as pharmacy, food, gourmet power and chemistry.

The mini plate spinner centrifuge features an automatic scraper device for easy discharge of filter cake, ensuring efficient operation. With a full close structure and multiple safety protections in place, this centrifuge guarantees the safety of personnel and prevents material contamination. Additionally, the unit's easy-to-maintain design, low noise levels, and stable operation make it a reliable choice for a variety of applications.

Team Strength:

Our Highly Automated Plate Spinner Centrifuge is a testament to the strength of our dedicated team. With years of experience in the field of laboratory equipment design and production, our team has worked tirelessly to create a cutting-edge centrifuge that offers unparalleled performance and efficiency. From our skilled engineers to our knowledgeable technicians, every member of our team plays a vital role in ensuring that our centrifuge meets the highest standards of quality and reliability. When you choose our plate spinner centrifuge, you're not just getting a superior product – you're also benefiting from the expertise and teamwork of our exceptional team.

Our Highly Automated Plate Spinner Centrifuge showcases unparalleled team strength in its cutting-edge design and functionality. With a team of skilled engineers and technicians behind its development, this centrifuge boasts superior precision and efficiency in separating liquids and solids. The seamless collaboration between our technical experts ensures optimal performance and reliability, giving you peace of mind in your laboratory operations. Our team's commitment to innovation and quality shines through in every aspect of this centrifuge, making it a top choice for laboratories looking for advanced centrifugation solutions. Trust in our team's strength to deliver exceptional results every time.

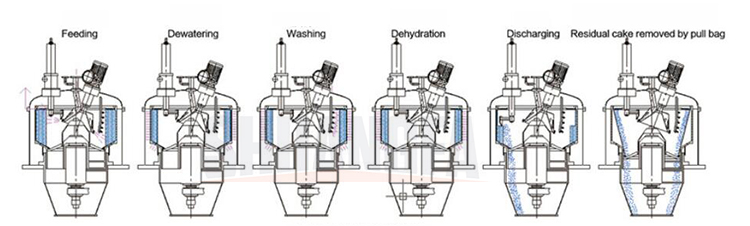

Working Principle of Automatic Scraper Bottom Discharge Centrifuge:

The liquid material feeded into the basket of the centrifuge that is rotating at high speed through a feeding pipe, and under action of the centrifugal field, the material passes through the filter cloth (screen) for filtration. Then the liquid phase discharges through the discharge pipeline, while the solid phase is retained in the basket. Feeding stops once the basket is filled with the material, then wash the solid cake, and discharge the washing liquid through filtration. The centrifuge continues to rotate to spin-dry the solid cake. After the solid cake meets the requirements for separation, the centrifuge reduces its speed, and removes the cake by means of the scraper, then discharges the cake out of the centrifuge. The centrifuge further reduces its speed so that the pneumatic pulling bag device moves reciprocally to shake off the residual solid cake, thus completely eliminating the solid cake.

Structure of Automatic Scraper Bottom Discharge Centrifuge, Bag-pulling Centrifuge:

Structure of Automatic Scraper Bottom Discharge Centrifuge, Bag-pulling Centrifuge:

Features of Products

1, Easy to replace the filter bag, with reliable self-locking. 2, Meet the GMP specifications and ant-explosion requirement, Large turnover or overall turnover cover+CIP online cleaning system. 3, Automatic scraper device, easy to discharding filter cake. 4, Small vibration, low noise and stable operation, convenient to maintenance. 5, Adopt the cake layer control device, effectively control the feeding amount of material, prevent the overload of centrifuge. 6, The basket, 100% weld flaw detection, high precision, large filtering area. 7, Full close structure, effectively prevent material from contamination, and ensure the safety of personnel. 8, Uniform distribution, reduce the distribution vibration. 9, Multiple safety protection, for example, overvibration protection, overcurrent protection, temperature control protection etc. 10, Cake removal rate higher than 99%.

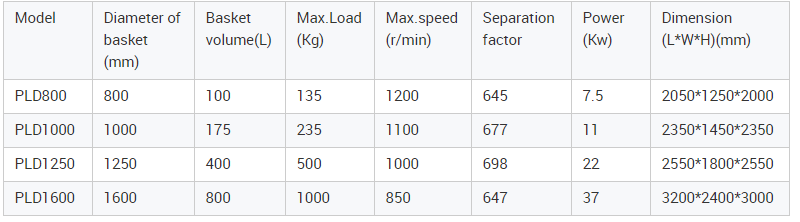

Paramter:

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1