Algae harvesting centrifuge | Chlorella harvesting tube centrifuge | Microalgae harvesting centrifugeAlgae harvesting tube centrifugeMicroalgae are a type of autotrophic plant widely distributed on land and in the ocean, with abundant nutrients and high photosynthetic efficiency. They belong to lower aquatic plants, with an average size of only about 5 micrometers per microalgae. Microalgae have a wide variety of species, usually referring to microorganisms that contain chlorophyll A and are capable of photosynthesis.

Classes are raw materials in many industrial branches. SHENZHOU provides an innovative process for efficient algae harvesting. The microalgae concentrate can be dehydrated to a solid content of 22-25% using a microalgae harvesting tube centrifuge. And this special dehydration tube separator can efficiently concentrate fine and soft algal cells without causing cell rupture.

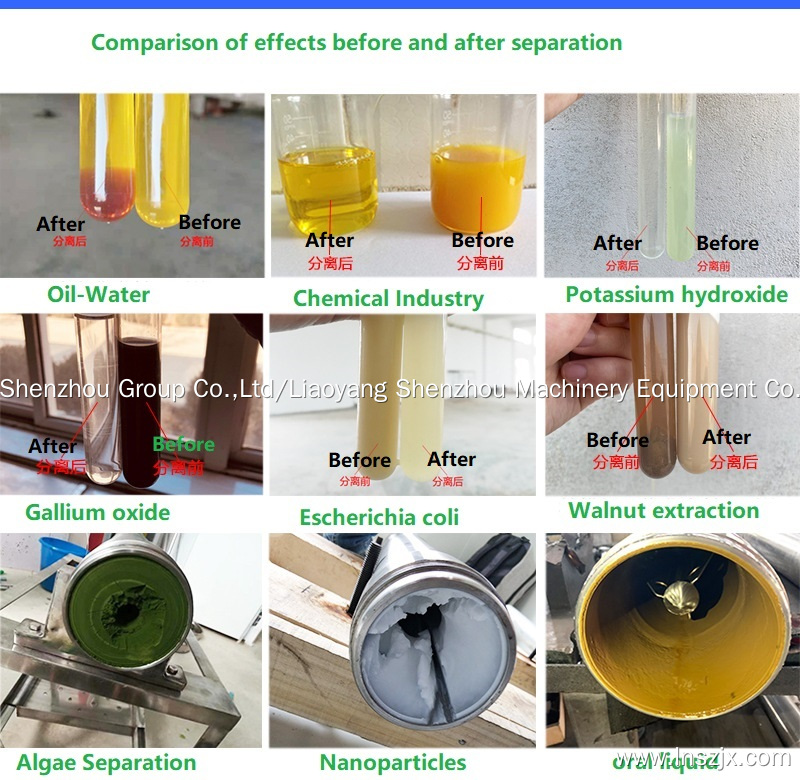

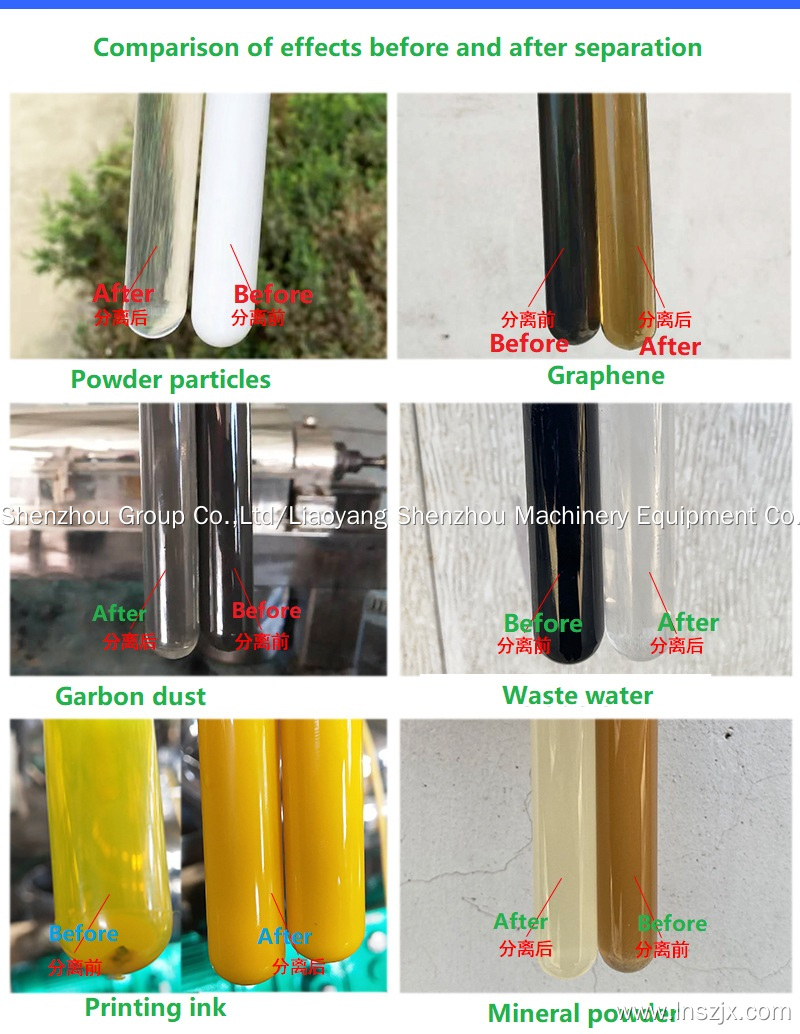

The 2 Phase Centrifuge is designed for efficient microalgae harvesting, offering a core attribute of fast and thorough separation of algae from water. With its advanced technology, this centrifuge provides value attributes of high oil production efficiency and environmentally friendly operation. Its product function attributes include the ability to purify wastewater, produce single-cell protein, and manufacture renewable energy using microalgae biomass.

At Microalgae Technologies, our team strength lies in our expertise in centrifuge technology and sustainable practices. Our team of engineers and researchers are dedicated to developing innovative solutions for efficient microalgae harvesting. With a deep understanding of the unique challenges in the industry, we work together to optimize the design and functionality of our 2 Phase Centrifuge, ensuring maximum yield and minimal energy consumption. Our commitment to teamwork and collaboration allows us to deliver high-quality products that meet the needs of our customers and contribute to a more sustainable future. Trust in our team's strength to provide you with reliable and effective microalgae harvesting solutions.

At the heart of our Microalgae Harvesting Centrifuge | 2 Phase Centrifuge lies our unparalleled team strength. Comprised of industry experts and specialists, our team is dedicated to providing top-notch centrifuge technology that revolutionizes microalgae harvesting processes. With years of experience and a passion for innovation, our team ensures that every product is meticulously designed and manufactured to meet the highest standards of quality and efficiency. By leveraging our team's collective expertise, we are able to deliver a centrifuge that not only simplifies the harvesting process but also maximizes productivity and performance, setting a new standard in the industry.

The application of microalgae in foodThe production of algal protein is rapidly developing, with Chlorella vulgaris, Scenedesmus obliquus, crescentia, and spirulina already being used as protein sources. Chlorella vulgaris, spirulina, and Dunaliella salina are also released in the health product market or used as food additives in the form of powders, pills, extracts, etc.

|  |

Animal feedArtificially cultivated as bait for planktonic animals, successfully used for feeding fish or as animal plankton (such as red worms, oysters, scallops, shrimp, etc.)

Environmental purificationCombining wastewater treatment with the production of single-cell protein (SCP), the treatment of pig manure wastewater from biogas anaerobic fermentation resulted in a spirulina production of 5g/m2/d. The use of reactor membrane technology can solve the problem of subsequent separation of algae and water. Microalgae grow to remove nitrogen and phosphorus, recalcitrant organic matter, and heavy metal ions such as Co, Mn, and Hg. Microalgae can also absorb certain concentrations of NOx, SOx, and H2S, and research on cultivating microalgae for environmental protection has already begun in domestic universities.

Renewable energy manufacturingMicroalgae are a type of biomass energy source Microalgae are excellent raw materials for preparing liquid fuels. The biomass fuel prepared by microalgae pyrolysis has a high calorific value, which is 1.4-2 times that of wood or crop straw. Compared with other biomaterials, microalgae have a relatively high oil production efficiency. The principle of microalgae oil production is actually to use photosynthesis to convert carbon dioxide into microalgae's own biomass, thereby fixing carbon elements. Then, through induction reactions, microalgae's own carbon substances are converted into oil. Finally, physical or chemical methods are used to convert the oil inside microalgae cells into extracellular oil, which is refined and processed to produce biodiesel

|  |

In essence, a long-standing 2 Phase Centrifuge organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of 2 Phase Centrifuge come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. 2 Phase Centrifuge QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the 2 Phase Centrifuge, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

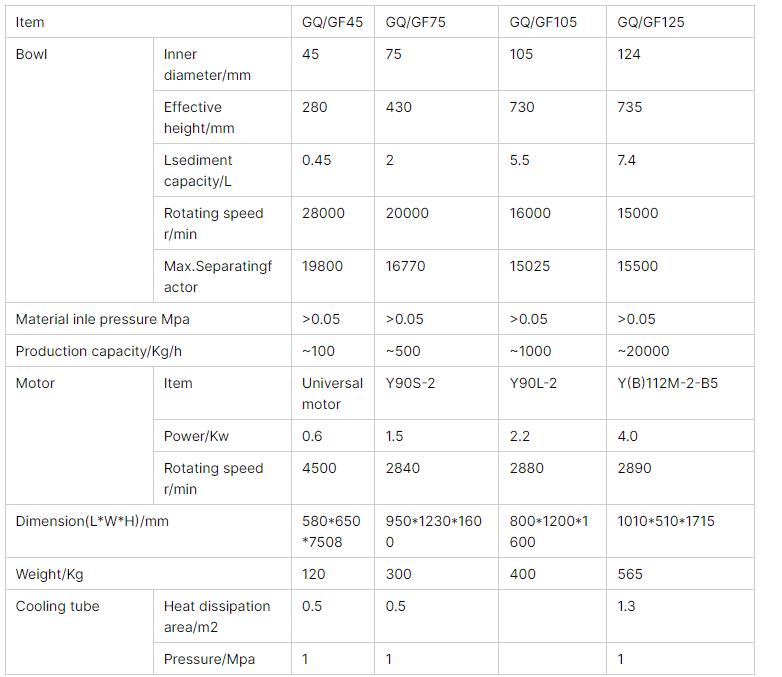

Yes, if asked, we will supply relevant technical details regarding Shenzhou. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1