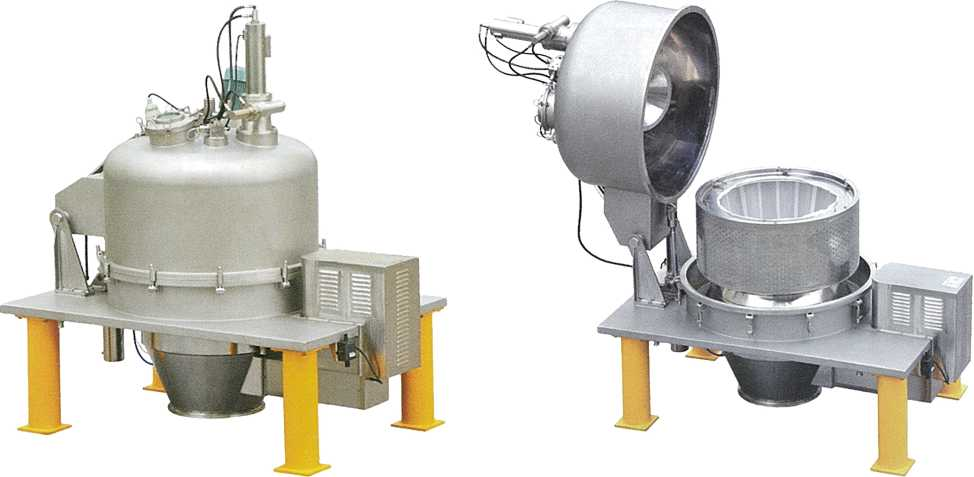

PLD Series Bottom Scraper Discharge Centrifuge - Superior Performance

Product advantages

The PLD Series Bottom Scraper Discharge Centrifuge offers superior performance with its efficient and reliable bottom scraper discharge mechanism that ensures thorough and consistent separation of solids and liquids. The centrifuge is equipped with advanced features such as variable speed control and automatic process monitoring, providing precise and customizable operation for different applications. Its robust design and high-quality components make it a durable and long-lasting solution for various industrial processes.

Team strength

Team strength is a core attribute of our PLD Series Bottom Scraper Discharge Centrifuge, offering superior performance in industrial applications. Our dedicated team of engineers and technicians have collaborated to design and develop a centrifuge that exceeds industry standards. With their collective expertise and innovative approach, we have created a product that is robust, reliable, and efficient. Our team's commitment to quality ensures that the centrifuge operates with precision and consistency, providing exceptional results for our customers. Trust in the team strength behind our PLD Series Bottom Scraper Discharge Centrifuge for unparalleled performance and reliability.

Enterprise core strength

At the core of our PLD Series Bottom Scraper Discharge Centrifuge is a team of dedicated engineers and designers working together to create a superior performance product. Our team strength lies in our deep understanding of centrifuge technology and our commitment to continuous innovation. By collaborating and leveraging each team member's expertise, we are able to deliver a high-quality product that exceeds customer expectations. In addition to our technical capabilities, our team strength also encompasses a strong customer focus and a dedication to providing excellent service and support. Choose our centrifuge for reliable results backed by a strong team behind the scenes.

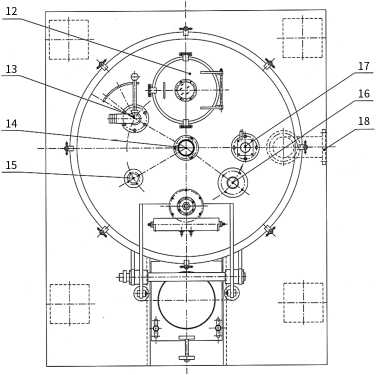

Product Description

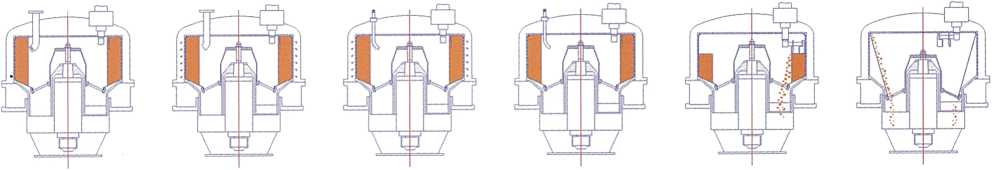

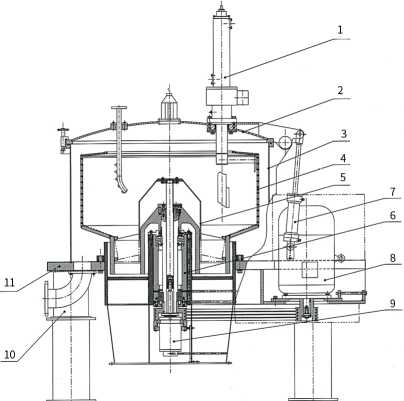

OPERATING PRINCIPL

* Removing the residual solid cake by bag - pulling method. Eliminate all solid cakes left over the process of scraper

discharging through reciprocal movement of the pneumatic pulling bag device, to realize complete discharging and filtering cloth regeneration.

* External cylinder+rod drive design, reliable in work

* Fully-enclosed discharge hopper design separating the material from the driving components of the centrifuge.

Feed type: Inclined feed disk, side feed pipe, middle feed pipe and material level detection device

Scraper discharge: Pneumatic, hydraulic and liquid-phase skimming disc

Motor drive: Common motor, inverter-duty motor and explosion- proof motor

Safety protection: Nitrogen protection (anti-explosion) system, vibration protection, temperature protection, electric-mechanical interlocking, speed monitoring and overload protection.

CIP system: Cleaning ball and spray pipe

Washing mode: Atomized nozzle rinsing, feed disk washing, pulse type washing

Nitrogen protection system: Automatic control device, hydraulic sealing device and gas -liquid separator.

Product parameters

Items | Model | ||||||||

PLD1000 | PLD1250 | PLD1400 | PLD1600 | PLD1800 | |||||

Basket Dia(mm) | 1000 | 1250 | 1400 | 1600 | 1800 | ||||

Basket Volume(L) | 180 | 400 | 600 | 800 | 1250 | ||||

Max. load(kg) | 230 | 500 | 700 | 1000 | 1500 | ||||

Max.Rotating speed (r/min) | 1100 | 1000 | 950 | 850 | 800 | ||||

Centrifuge force | 677 | 700 | 700 | 647 | 645 | ||||

Motor (kw) | 15 | 22 | 30 | 37 | 55 | ||||

Dimension (LxWxH) (mm) | 2210*1530*2200 | 2550*1800*2550 | 3020*2100*2720 | 3200*2400*3000 | 3500*2500*3300 | ||||

Weight (kg) | 3500 | 5000 | 9000 | 12000 | 17000 | ||||

Product service

2. Supply reference process flow chart .

3. Supply on-site installation and operation test

4. Integration for control system and process

5. Customized size and structure

6. 12 Months guarantee period from machine arriving date.

7. Sufficient spare parts in stock are available .

8. Technicians are available for overseas service.

9. 24 hours technical consultation.

10. The customer could get trained by our experienced technician.

FAQ

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team.More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famous good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.