Shenzhou | Bulk buy 2 phase Centrifuge manufacturers

Guided by scientific and technological innovation, Shenzhou always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. 2 phase Centrifuge Shenzhou have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Bulk buy 2 phase Centrifuge manufacturers, or would like to partner up, we'd love to hear from you.The product has been approved to meet with the industry-recognized quality standards.

Product Introduction

A disc stack centrifuge is a specifically designed industrial centrifuge with a stack of cone-shaped discs. The additional surface increases the settling area multi-fold and reduces the settling distance.

A disc-stack centrifuge separates immiscible liquids and suspended solids from contaminated fluids. G-forces up to 10,000 Gs cause the particles’ sedimentation on the disc surface where they flocculate and move toward the centrifuge bowl periphery.

The accumulated solids are self-ejected or manually removed from the disc centrifuge bowl.

Think of the discs in the centrifuge bowl splitting the liquid column into thin slices between the inter-disc space. The rotating discs impart the rotational velocity to the incoming stationary (non-rotating) fluid quickly due to the liquid’s viscosity.

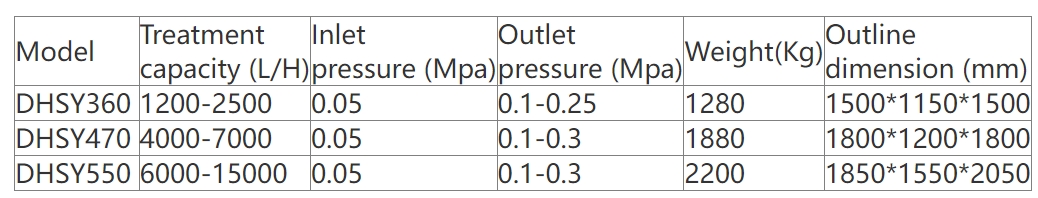

technical Parameter:

FAQ

FAQ

How does a disc stack centrifuge work?

A disc stack centrifuge has a rotating bowl with closely spaced conical discs. These discs split the incoming fluid into thin layers, imparting the bowl's rotation to the process fluid instantaneously. The fluid's rotation generates high centrifugal forces causing the heavier solids to separate from the fluid causing separation.

What is the purpose of the conical discs in a disc stack centrifuge?

The conical discs partition the fluid column into layers. The process fluid passes radially between these discs. The close proximity of these discs decreases the settling distance for the sediment, thus enhancing settlement speed and efficiency.

What is the design of a disc stack centrifuge?

The design features of a disc stack centrifuge feature a rotating bowl with a set of thin, closely spaced conical discs within. The fluid to be separated passes through the inter disc space causing the fluid to also rotate. The centrifugal force generated by the rotation causes the solids of higher density to settle on the disc surface while the separated fluid flows out of the bowl. This separation of the solids from fluid is the primary function of the disc stack centrifuge.

What exactly is the disc stack in a disc stack centrifuge?

A set of conical plates (discs) that are vertically stacked is the disc stack in a disc stack centrifuge. The centrifuge bowl houses this stack of thin plates. Each disc has thin metal strips attached to it, and these strips act as vertical spacers creating a space between the discs.

What is the particle size efficiency of a disc stack centrifuge?

A disc stack centrifuge has a particle size efficiency of 0.5-microns for metal particles and 1-micron for non-metal particles.

Advantage

As with all separation equipment, disc centrifuges have a specific niche area of application where they deliver the optimum solution for separating solids from liquids or liquids from solids and liquids.

However, they also have limitations to their applications, and we have discussed the disadvantages of disc centrifuges in a different article.

Disc centrifuges are capital-intensive equipment. However, reduced maintenance costs and higher production levels quickly make up for initial expenses. Typically the upfront cost is recovered within 1 to 2 years of operation.

A disc centrifuge has several benefits compared to filters. The following list highlights some of these benefits.

Particle and water separation in a single operation

Removal of particles down to a 1-micron level

Consistent throughput without flow reduction (filters clog)

Water separation is continuous

Minimized O&M cost (Operation and Maintenance)

Negligible disposal costs (no filter or membrane media to dispose of)

No loss of lubricant additives