Yeast Centrifuge Separator: 2 Phase Disc Centrifuge

Product features

The Yeast Centrifuge Separator: 2 Phase Disc Centrifuge offers high separation efficiency with a maximum speed of 10000rpm, allowing for complete yeast separation and a production capacity of up to 20000L/H. Its fully enclosed design and carbon dioxide protective gas interface help maintain low oxygen content in the beer, preserving its flavor. With autonomous control and adjustable parameters, this centrifuge ensures stable operation and precise separation based on the desired product taste.

Company profile

With a rich history in manufacturing specialized centrifuge equipment, our company is a trusted leader in the industry. Our Yeast Centrifuge Separator is a top-of-the-line 2 Phase Disc Centrifuge, designed for efficiently separating yeast in food and beverage production processes. Our team of experts ensures that each centrifuge is of the highest quality, providing reliable performance and optimal results for our customers. With a commitment to innovation and excellence, we strive to continuously improve and enhance our products to meet the evolving needs of our clients. Trust in our expertise and experience to deliver exceptional centrifuge solutions for your business.

Why choose us

Our company specializes in the manufacturing and supply of high-quality yeast centrifuge separators, such as the 2 Phase Disc Centrifuge. With years of experience and expertise in the industry, we are dedicated to providing top-of-the-line equipment that meets the needs of our customers. Our products are designed to efficiently separate yeast from various liquid solutions, ensuring optimal performance and productivity. The precision and reliability of our centrifuge separators make them an essential investment for any business in the food and beverage or pharmaceutical industries. Trust our company to deliver top-notch equipment that drives success and efficiency in your operations.

Product Description

Yeast Centrifuge Separator is widely used in brewery for separation of yeast and clarification of beer. The liquid seal technology may functionally prevent from loss of carbon dioxide and avoid mixing of air during separating beer. The model is also used to separate similar material (e.g. Juice, beverage etc.)

The machine adopts automatic control, and has the advantages of high efficiency, low material consumption, convenient operation and economic maintenance cost. It adopts small piston structure for gaining variable discharging capacity, and PLC control both partly and fully discharging in order to get rid of sediment. The clear liquid is pumped out by centripetal pump, the sludge is discharged automatically and partly. The machine is one kind of rotary machine with high speed. After accurate dynamic balancing, it can run for long time with low vibration, safety and security.

Centrifugal separation technology for beer

With the continuous improvement of people's living standards, the requirements for beer flavor, taste and type are getting higher and higher. Huading separator has more than 60 years of manufacturing experience, which can help you improve the production process and save production costs. Whether it is industrial beer production or craft beer, Huading centrifuges can help you stand out in the beer field.

Product description

The BRSX series beer disc separator adopts the upper feeding method, the separated beer is discharged from the upper end of the machine, and the separated yeast is discharged from the middle of the machine. The entire process is autonomously controlled by the system without manual intervention. This equipment adopts a fully enclosed design and is equipped with a carbon dioxide protective gas interface. In the production and operation process, the air is isolated, and the dissolved oxygen content is extremely low, which greatly protects the flavor of the beer; at the same time, in the separation process, it can be based on the needs of the product taste. , Adjust the parameters of the centrifuge to decide whether to completely separate the yeast or leave a small part.

Benefits

-High separation efficiency: up to 10000rpm, complete yeast separation, and production capacity up to 20000L/H.

-Low oxygen content: After the separation, the dissolved oxygen content in the beer is low, which protects the flavor of the beer.

-Stable product operation: Huading centrifuge product design is reasonable, with low operating noise.

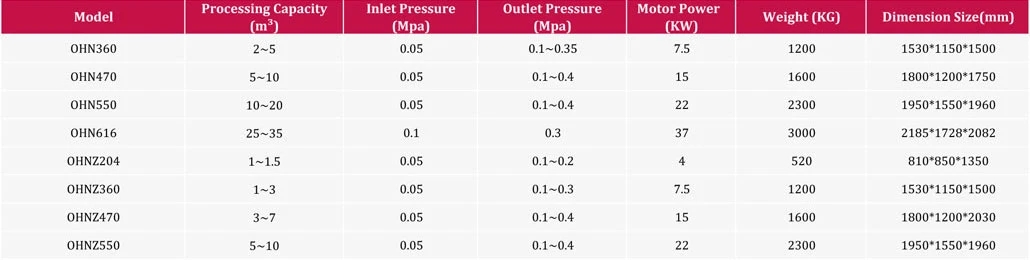

Technical Parameter