What's decanter centrifuge?

A decanter centrifuge is a device that employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge (also known as solid bowl centrifuge) separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries. There are several factors that affect the performance of a decanter centrifuge, and some design heuristics are to be followed which are dependent upon given applications.

The operating principle of a decanter centrifuge is based on separation via buoyancy. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation, producing a g-force equivalent to between 1000 and 4000 G's. This reduces the settling time of the components by a large magnitude, whereby mixtures previously having to take hours to settle can be settled in a matter of seconds using a decanter centrifuge. This form of separation enables more rapid and controllable results.

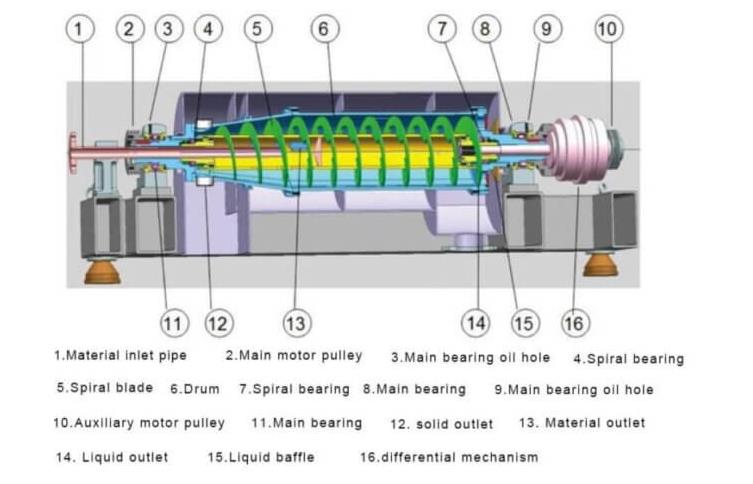

The feed product is pumped into the decanter centrifuge through the inlet. Feed goes into a horizontal bowl, which rotates. The bowl is composed of a cylindrical part and a conical part. The separation takes place in the cylindrical part of the bowl. The fast rotation generates centrifugal forces up to 4000 x g. Under these forces, the solid particles with higher density are collected and compacted on the wall of the bowl. A scroll (also screw or screw conveyor) rotates inside the bowl at a slightly different speed. This speed difference is called the differential speed. This way the scroll is transporting the settled particles along the cylindrical part of the bowl and up to the end conical part of the bowl. At the smallest end of the conical part of the bowl, the dewatered solids leave the bowl via discharge opening. The clarified liquid leaves through a paring disc (internal centripetal pump).

With a 3 phase decanter centrifuge, it is possible to separate 3 phases from each other in one process step only. For example, two liquids which cannot be mixed because of different densities (e.g. oil and water) are separated from a solids phase. The heavy liquid (water) collects in the middle between the oil and the solids layer. Thus the two liquids separated from each other can be drawn off from the decanter. The solids are transported via the scroll to the discharge openings as it happens also in 2-phase separation.[2]

Typical applications of 3-phase separation are the production of edible oils such as olive oil, oil sludge processing, the production of biodiesel etc.

Through the feed, the separation medium to be processed can be input into the centre of the infeed chamber of the scroll, where it is accelerated. The throughput will have an influence on the residence time.[3]

The separation medium reaches its maximum speed in the decanter bowl, causing the solids to settle on the bowl inner diameter. A characteristic feature of the bowl is its cylindrical/conical shape.

There is a differential speed between the decanter bowl and the scroll, which is created by a gear unit on the industrial decanter centrifuges. The differential speed determines the solid content in the outfeed.

Pond depth / Weir discs

The clarified liquid flows to the cylindrical end of the bowl in the decanter centrifuFood processingge, from where it runs out through openings in the bowl cover. These openings contain precisely adjustable weir discs/weir plates by means of which the pond depth in the bowl can be set. The weir discs determine the filling volume of the bowl.

The main application of decanter centrifuges is to separate large amounts of solids from liquids on a continuous basis. They are also used to wash and dry various solids in industry, such as polystyrene beads, clarify liquids and concentrate solids. Table 1.0 displays various examples of the utilisation of decanter centrifuges in various industries.

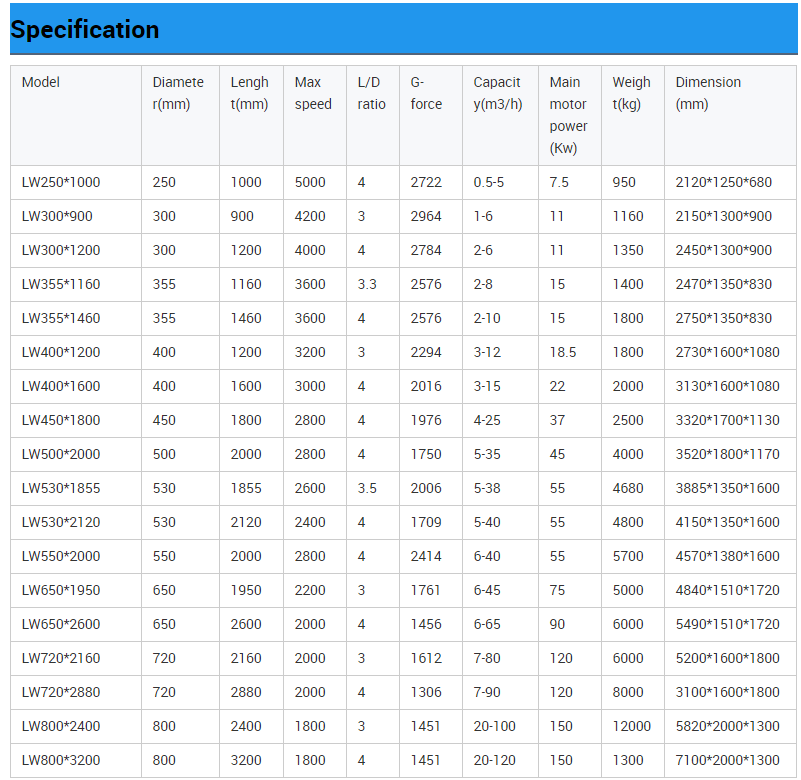

Technical Parameter of decanter centrifuge 2 phase :

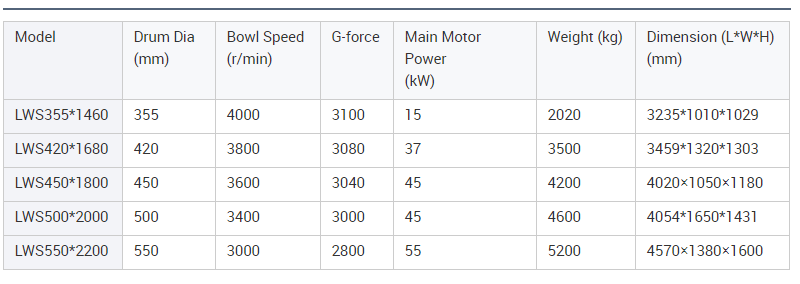

Technical Parameter of decanter centrifuge 3 phase :

Industries with corresponding examples that use decanter centrifuges

Food processing:

Edible animal fat

Animal protein

Protein recovery

Plant oils such as olive oil and vegetable oil

Wine (clarification)

Fruit, berries and vegetable juice

Soy protein

Dairy (recovery of lactose, whey fines and cheese fines)

Coffee and tea

Pectin

Petrochemical/oil:

Refining

Dewatering

Oil well drilling

Lubricating oil additives

Waste oil stream recycling

Waste recycling:

Municipal wastewater

Cleaning of wash water

Fish processing

Fish meal

Fish oil

Chemical:

Herbal medicines

Chemical extraction

Mineral processing:

Bentonite and titanium dioxide manufacturers

Kaolin clay and calcium carbonate processing

Organic chemical industry

Organic intermediate and end products

Polymer industry:

Thermoplastics for example PVC, synthetic rubber and fibres

Inorganic chemical industry:

Bleaching agents

Acids

Silica products

Fertilisers

Advantages of decanter centrifuge

Decanter centrifuges have a clean appearance and have little to no odour problems.

Not only is the device easy to install and fast at starting up and shutting down but also only requires a small area for operation compared to other competitive processes.

The decanter centrifuge is versatile as different lengths of the cylindrical bowl section and the cone angle can be selected for different applications. Also, the system can be pre-programmed with various design curves to predict the sludge type, while some competitive processes, such as a belt filter press, cannot change the belt type to operate for different sludge types. Its versatility allows the machine to have various functions such as operating for thickening or dewatering.

The machine can operate with a higher throughput capacity than smaller machines. This also reduces the number of units required.

The device is simple to optimise and operate as it has few major variables and reliable feedback information.

The decanter centrifuge has reduced labour costs compared to other processes, as it requires low continuous maintenance and operator attention.

Compared to some competitive process such as the belt filter process, the decanter centrifuge has more process flexibility and higher levels of performance.

The main types of decanter centrifuges are the vertical orientation, horizontal orientation and Conveyor/Scroll.

In vertical decanter centrifuges, the rotating assembly is mounted vertically with its weight supported by a single bearing at the bottom or suspended from the top. The gearbox and bowl are suspended from the drive head, which is connected to the frame.[5] The vertical decanter allows for high temperature and/or high-pressure operation due to the orientation and the rotational seals provided at one end. However, this makes the device more expensive than the horizontal decanter centrifuge, which is non-pressurised and open. The advantage of the vertical machine over the horizontal machine is that the noise emitted during production is much lower due to less vibration.

In horizontal decanter centrifuges, as shown in figure 1, the rotating assembly is mounted horizontally with bearings on each end to a rigid frame, which provides a good sealing surface for high-pressure applications.The feed enters through one end of the bearings, while the gearbox is attached to the other end and is operated below the critical speed. Capacities range up to 40,000 pounds (18,000 kg) of solids per hour with liquid feed rates of up to 300 US gallons (1.1 m3) per minute.The horizontal machine is arranged in a way that slurry can be introduced at the centre of a rotating horizontal cylindrical bowl.The scroll discharge screw forces the solids to one end of the bowl as it is collected on the walls. This orientation is the most common design implemented in the industry.

In conveyor decanter centrifuges the conveyor or scroll fits inside a rotating bowl and carries the solids settled against the wall, pushing them across a beach towards the underflow where the solids discharge. The conveyor allows for an increase in separation efficiency and feed capacity.

The separation process in a decanter centrifuge relies on a few process characteristics such as centrifugal force or G-force, sedimentation rate and separating factor, differential speed between the conveyor and bowl, and clarity of the liquid discharge.

Decanter centrifuges require a centrifugal force for the separation of the solids from the liquid. This characteristic is dependent on the radius of the centrifuge and its angular rotational speed. A decanter centrifuge applies a force equivalent to several thousand G's, which reduces the settling time of the particles. It is also favoured to maintain a large G-force, which will result in an improved separation.

The rate at which sedimentation occurs is an important characteristic of the decanter centrifuge separation process. The sedimentation rate is influenced by the particle size, the shapes of the particles, their density differential between solid and liquid and the viscosity of the liquid. This process characteristic can be improved by utilizing flocculating agents. The sedimentation rate is also dependent on the separating factor of the decanter centrifuge, which is related to the centrifugal force.

The exterior bowl and the scroll conveyor rotate at different high speeds. This differential speed between the two is accountable for the sedimentation throughout the decanter centrifuge cylinder. A high differential speed results in a smaller residence time of the cake settlement, so it is necessary to keep the cake thickness to a minimum to avoid impairing the discharge quality. Keeping the cake thickness to a minimum also aids in the improvement of the cake dewatering process. For this reason, it is necessary to obtain an optimal differential speed to balance the cake thickness and quality.

The characteristic above all affects the clarity of the liquid output which is dependent on the volumetric throughout rate,[5] where a higher flow rate will result in a poor liquid clarity. Another characteristic that influences the clarity of the liquid output is the differential speed. A low differential speed results in a better clarity, therefore, aiding in the separation process. The G-Force also plays a role in the clarity of the liquid discharge. Higher G-force results in an increase in the separation of the solid particles from the liquid and yields a better clarity.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1