Decanter centrifuge for extracting fruit- or vegetable juice was shown to be applicable to juice extraction from sweet and sour cherries, apricots and peaches. The machine was fed fruit mash at incrementally higher flow rates and the suspended solids in the output juice were measured with a high-speed laboratory centrifuge. Accepting 3% (w/w) suspended solids as an acceptable level, machine capacity was about 0.36 kg/s (2800 lb/h), 0.38 kg/s (3000 lb/h), 0.23 kg/s (1800 lb/h), and 0.1 kg/s (790 lb/h) for peaches, sour cherries, apricots and sweet cherries, respectively. Peaches required pectolytic enzyme treatment for extraction of low suspended solids juice but sour cherries could be processed with or without enzyme treatment. Apricot proved more difficult to juice than peaches, requiring pectinase treatment and slower feed rates to achieve juice separation. Sweet cherries proved difficult to juice, requiring both low feed rates and extensive enzyme digestion for extraction. Nevertheless, with all fruit tested, yields of juice exceeded 80% (w/w) and were usually between 90 and 95%.

Decanter centrifuge for extracting fruit- or vegetable juice

II. Decanter centrifuge for extracting fruit- or vegetable juice characteristics

1.Unparalleled equipment investment costs and later-stage operation costs

2.Extremely low infrastructure investment and good on-site 3.operating environment

4.Diversified models, wide selection range, and complete engineering project

5.Modular design, easy to operate

6.Operator configuration and labor intensity

III. Technical characteristics of the Decanter centrifuge for extracting fruit- or vegetable juice

1.Not only equipment manufacturer but also system engineering service provider

2.Eddy current type spiral outlet

3.BD board technology

4.More economical in equipment investment and later-stage operation

5.High performance wear-and corrosion-resistant cemented carbide

6.High performance stainless steel

7.High-dryness screw conveyor and drum structure

8.High torque involute planetary gear differential

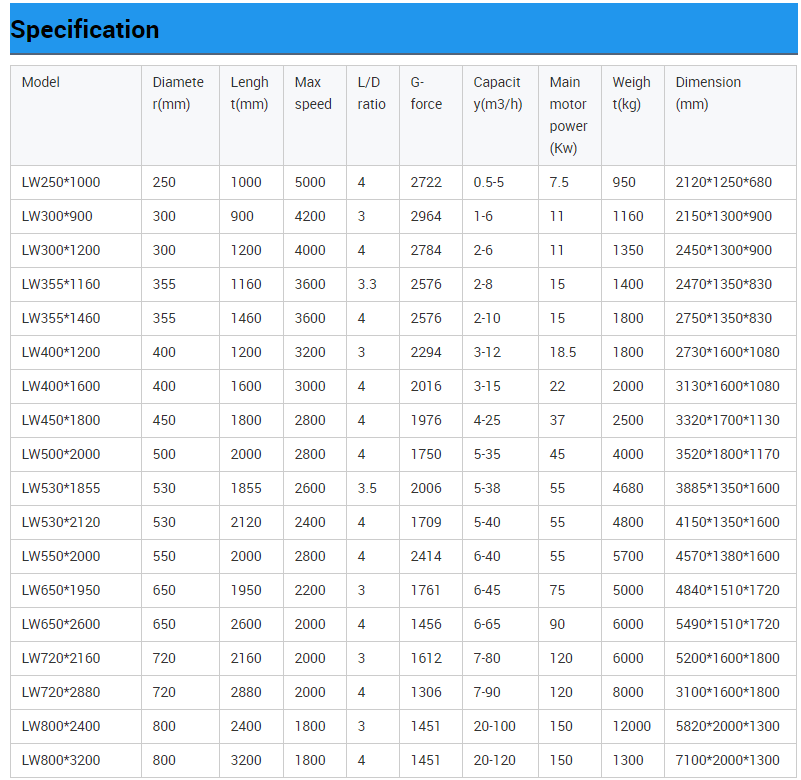

Decanter centrifuge for extracting fruit- or vegetable juice model and technical parameters

Outlet position local

1.CIP washing system

The fully automatic control system is equipped with a CIP washing system, which can effectively solve the problem that it is not completely cleaned during the shutdown process and effectively avoid the equipment troubles caused by artificial factors.

2.Humanized centrifuge configuration

a.Spiral bearing (in the drum, concealed) lubrication technology: the lubricant is filled from the outside of the hood.

b.The hood adopts a hinged opening structure and is equipped with a high-pressure gas strut to assist the opening.

3.Variable pitch technology

4.High rigidity screw rotor technology

Decanter centrifuge for extracting fruit- or vegetable juice parameter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1