When you need to separate solid / liquid mixtures with high solids content, you can choose a decanter centrifuge. In contrast to chamber filter presses, these solid vortex centrifuges or decanter centrifuges operate continuously. High centrifugal forces separate finely divided solid particles from the suspension.

Our decanter centrifuges are modular in design and can be used in a wide range of industries. Centrifuges can be optimally adjusted for specific applications. Applications range from sludge dewatering to classification or wet classification to solid classification.

Working Principle of High Dryness Decanter

•

Working Procedure

High dryness decanter can use limit space to fit together different stages of separation.

•

Mixing and Accelerating Stage

Sludge and chemical mixes in the specially designed feed chamber and accelerates together. This prepares the sludge for best separation.

•

Clarifying Stage

The flocculants sediments inside the bowl under centrifugal force, the clear liquid flows out of the weir at the end of the bowl.

•

Pressing Stage

Conveyor pushes the solid toward the discharge end. The sludge is further pressed by centrifugal force and the water comes out of the small holes of the sludge.

•

Double-direction Pressing Stage

In the conical part of the bowl wall, the sludge is pressed by specially designed double direction pressing effect. The specially designed conveyor produces axial pressing force and water comes out of the tiny holes of the sludge.

Control the Staying Time of Solid

In order to achieve best dewatering effect when flow rate or character of sludge changes, the solid content inside the bowl should be continuously controlled.This is controlled by the drive system of the conveyor. The drive system of the conveyor can measure real-time the solid content inside the bowl and adjust automatically, solid discharge torque automatically compensated.

Drive Technology

The reliable and excellent operation needs good cooperation of bowl drive and conveyor drive. SHENZHOU researches good drive combination, which can be recommended as best design to suit different applications.

Bowl Drive System

Alternatives includes: - AC Motor + Frequency Converter

- AC Motor + Hydraulic Coupling

- Other Special Ways

Conveyor Drive System

Alternatives includes:

Frequency converter back of forward drive

DVF multi-level planet control

-

Hydraulic motor with individual hydraulic pump

Other Special Ways

Introduction

Sludge dehydrator-horizontal solid bowl decanter, is key equipment of sludge dewatering unit. It uses centrifugal force to sediment solid content in the mixture. It is fit for liquid solid separation of suspension liquid with solid particle equipment diameter≥3μm, solid liquid density difference ≥0.5g/cm3,and weight concentration ≤10% or volume concentration ≤70%.

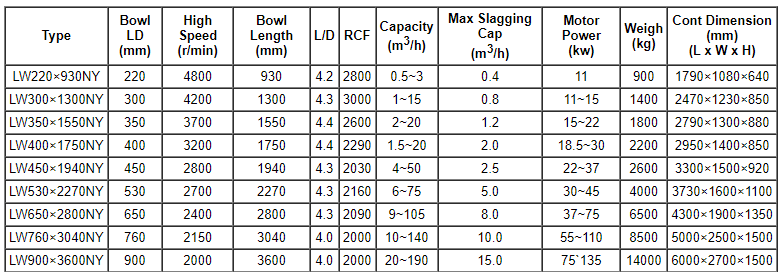

Our product includes 9 series (LW220, LW300, LW400,LW450, LW530, LW650, LW760, and LW900)of more than 100 machine types.

The machine can also be sorted by bowl type, such as thickening, dewatering, classifying, clarifying and etc, to fit different kinds of separation.

Our institute can also design, configure and manufacture different equipment. The Mobile sludge dewatering truck can also perform test on customer site. Customers are also welcomed to bring sample to our institute for testing.

In recent years, our company has been cooperating with world-famous centrifuge company. SHENZHOU has developed decanter series with bigger length/diameter ratio. The sedimentation zone of bowl of this decanter series is longer and the separation effect is enhanced. For more than seven years, this decanter series has been exported to developed countries in Europe and America.

Notes:

1.Actual capacity depends on character of mixture and treatment requirement.

2.Maximum solid discharge capacity is calculated assuming that the differential speed is 10r/min and the sludge is pressed in two directions.

3.Sludge feed concentration range is 0.5~0.6%.

4.Parts contacting the mixture are made from AISI321 or AISI316 stainless steel.

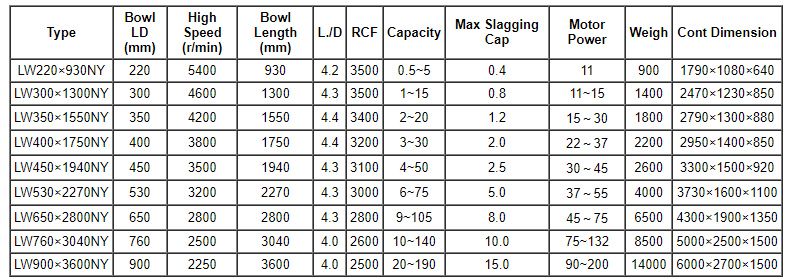

High Speed High Dryness Solid Bowl Decanter Specifications

Notes:

1.Actual capacity is related to character of mixture and treatment requirement.

2.Maximum solid discharge capacity is calculated assuming that the differential speed is 10r/min and the sludge is pressed in two directions.

3.Sludge feed concentration range is 0.5~0.6%.

4.Bowl material of above centrifuges is AISI329 stainless steel (centrifugally cast). Parts contacting the mixture are made from AISI321 or AISI316 stainless steel.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1